A road paving material using ceramic waste and construction waste and its preparation method

A technology of construction waste and ceramic waste, applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., can solve environmental pollution, secondary pollution and other problems, and achieve the effect of solving environmental pollution and preventing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

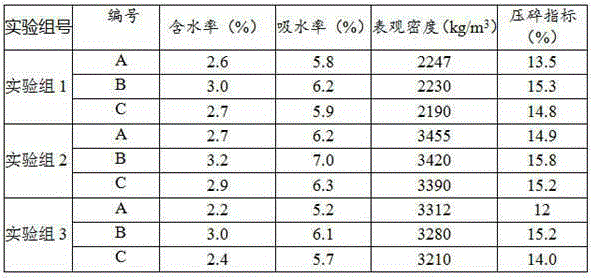

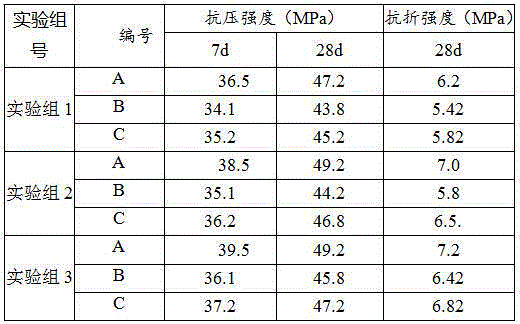

Embodiment 1

[0029] 1. Raw material ratio:

[0030] Portland cement 30 parts, ceramic waste fine aggregate 50 parts, construction waste coarse aggregate 120 parts, zeolite powder 15 parts, organic fiber 1 part, sodium sulfate 1 part, water reducer 1 part, polyurea gelling agent 1 part part, 0.5 part of inositol phosphate, 20 parts of water;

[0031] Among them, the ceramic waste fine aggregate is a fine aggregate with a particle size of 0.75 mm, which is produced by sorting, crushing, magnetic separation to remove waste metal, and spraying esterification after the waste produced in the ceramic production process is ground. particles;

[0032] The construction waste coarse aggregate is the particle size obtained after sorting, crushing, magnetic separation to remove waste metals and esterification spraying of concrete, waste concrete walls, and waste stones in construction waste. 5mm coarse aggregate particles;

[0033] The polyurea gelling agent is composed of epoxy resin, epoxy reactiv...

Embodiment 2

[0047] 1. Raw material ratio:

[0048] Portland cement 50 parts, ceramic waste fine aggregate 90 parts, construction waste coarse aggregate 160 parts, zeolite powder 20 parts, organic fiber 10 parts, sodium sulfate 5 parts, water reducing agent 2 parts, polyurea gelling agent 3 parts 1 part, 1 part of inositol phosphate, 40 parts of water;

[0049] Wherein, the ceramic waste fine aggregate is a fine aggregate particle with a particle size of 1 mm, which is made by grinding the waste produced in the ceramic production process after sorting, crushing, magnetic separation to remove waste metal, and esterification spraying. ;

[0050] The construction waste coarse aggregate is the particle size obtained after sorting, crushing, magnetic separation to remove waste metals and esterification spraying of concrete, waste concrete walls, and waste stones in construction waste. 20mm coarse aggregate particles;

[0051] Described polyurea gelling agent is made up of epoxy resin, epoxy ...

Embodiment 3

[0065] 1. As a preferred embodiment, the paving material is made of the following raw materials in weight ratio:

[0066] 35 parts of Portland cement, 70 parts of ceramic waste fine aggregate, 90 parts of construction waste coarse aggregate, 15 parts of zeolite powder, 5 parts of organic fiber, 3 parts of sodium sulfate, 1 part of water reducer, polyurea gelling agent 2 parts, 0.5 parts of inositol phosphate, 40 parts of water.

[0067] Among them, the ceramic waste fine aggregate is a fine aggregate with a particle size of 0.75 mm, which is produced by sorting, crushing, magnetic separation to remove waste metal, and spraying esterification after the waste produced in the ceramic production process is ground. particles;

[0068] The construction waste coarse aggregate is the particle size obtained after sorting, crushing, magnetic separation to remove waste metals and esterification spraying of concrete, waste concrete walls, and waste stones in construction waste. 15mm coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com