Assembling process of pattern ring and side plate of tire mold

An assembly process and tire mold technology, which is applied to tires, household appliances, and other household appliances, can solve the problems of reducing the service life of the pattern ring mold, damage to the structure of the pattern ring mold, and poor precision of the pattern ring mold, so as to prolong the service life and reusability, improve production quality, and avoid mold damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

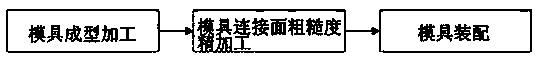

[0015] The first step: mold forming processing, the blank is installed according to the actual use requirements, and the three parts of the shell, the pattern ring and the side plate are sequentially processed, and the shell, the pattern ring and the side plate are all equipped with connecting thread ports and connecting surfaces. The connection surfaces are composed of horizontal planes and vertical planes, and the horizontal planes and vertical planes are perpendicular to each other;

[0016] The second step: finishing the roughness of the connecting surface of the mold, and processing the surface roughness of the connecting surfaces of the processed shell, pattern ring and side plate, and ensuring that the roughness of each connecting surface is Ra0.4 after processing;

[0017] Step 3: Mold assembly, firstly connect the housing with the connecting surface of the pattern ring, and position it through the connecting bolts, then heat the connected shell and the pattern ring eve...

Embodiment 2

[0019] The first step: mold forming processing, the blank is installed according to the actual use requirements, and the three parts of the shell, the pattern ring and the side plate are sequentially processed, and the shell, the pattern ring and the side plate are all equipped with connecting thread ports and connecting surfaces. The connection surfaces are composed of horizontal planes and vertical planes, and the horizontal planes and vertical planes are perpendicular to each other;

[0020] The second step: finishing the roughness of the connecting surface of the mold, and processing the surface roughness of the connecting surfaces of the processed shell, pattern ring and side plate, and ensuring that the roughness of each connecting surface is Ra0.8 after processing;

[0021] Step 3: Mold assembly, firstly connect the housing with the connecting surface of the pattern ring, and position it through the connecting bolts, then heat the connected shell and the pattern ring eve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com