Flux composition and solder composition

A composition and flux technology, applied in the field of flux compositions and solder compositions, can solve the problems of discoloration of the flux, the meltability of the solder composition may not be sufficient, etc., to prevent the discoloration of copper foil, and to achieve excellent solder coating expansion. , the effect of excellent solder melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

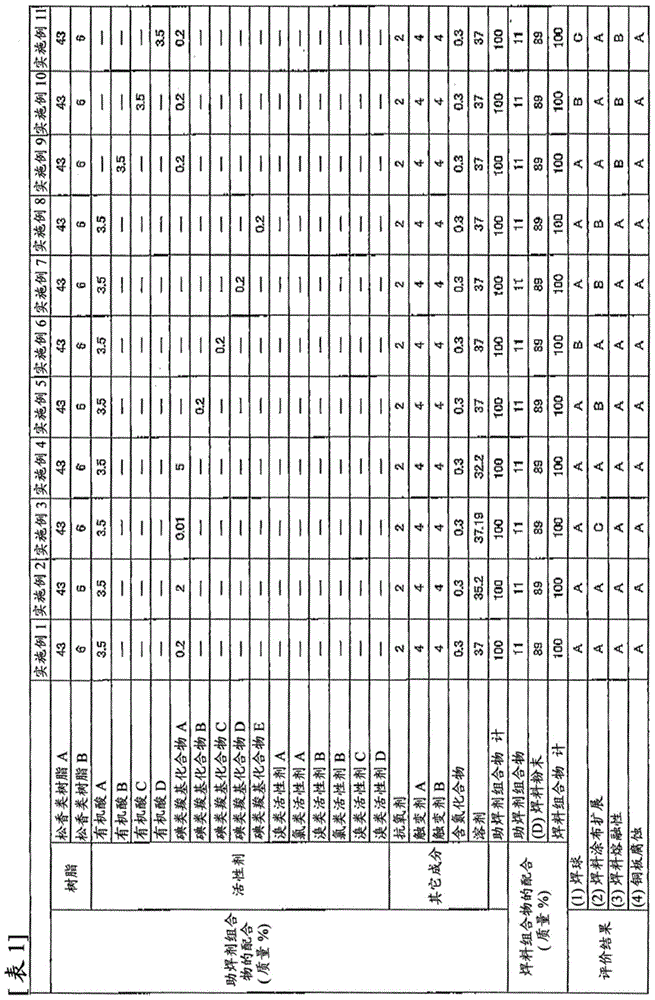

Embodiment 1

[0071] Rosin resin A43 mass %, rosin resin B6 mass %, organic acid A3.5 mass %, iodine carboxyl compound A0.2 mass %, antioxidant 2 mass %, thixotropic agent A4 mass %, thixotropic agent B4 mass %, 0.3 mass % of a nitrogen-containing compound, and 37 mass % of a solvent were put into a container, respectively, and mixed using a grinder, and flux was obtained.

[0072] Then, 11% by mass of the obtained flux composition and 89% by mass of solder powder were put into a container, and mixed with a kneader for 2 hours to prepare a solder composition having a composition shown in Table 1 below.

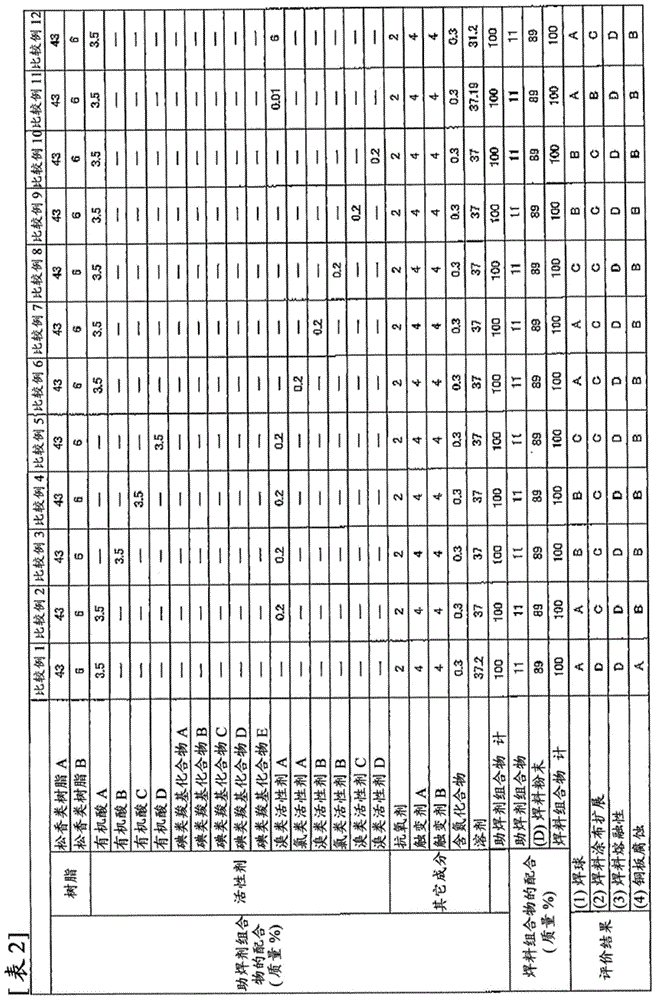

Embodiment 2~11

[0074] A flux composition and a solder composition were obtained in the same manner as in Example 1 except that each material was blended according to the composition shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com