A composite ion-adsorbing carbon membrane and its preparation method

A kind of ion adsorption and composite technology, applied in the field of materials, can solve the problems of difficult regeneration of activated carbon, increase of treatment cost, limitation of adsorption effect, etc., and achieve the effect of abundant reserves, good treatment effect and strong electrostatic attraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

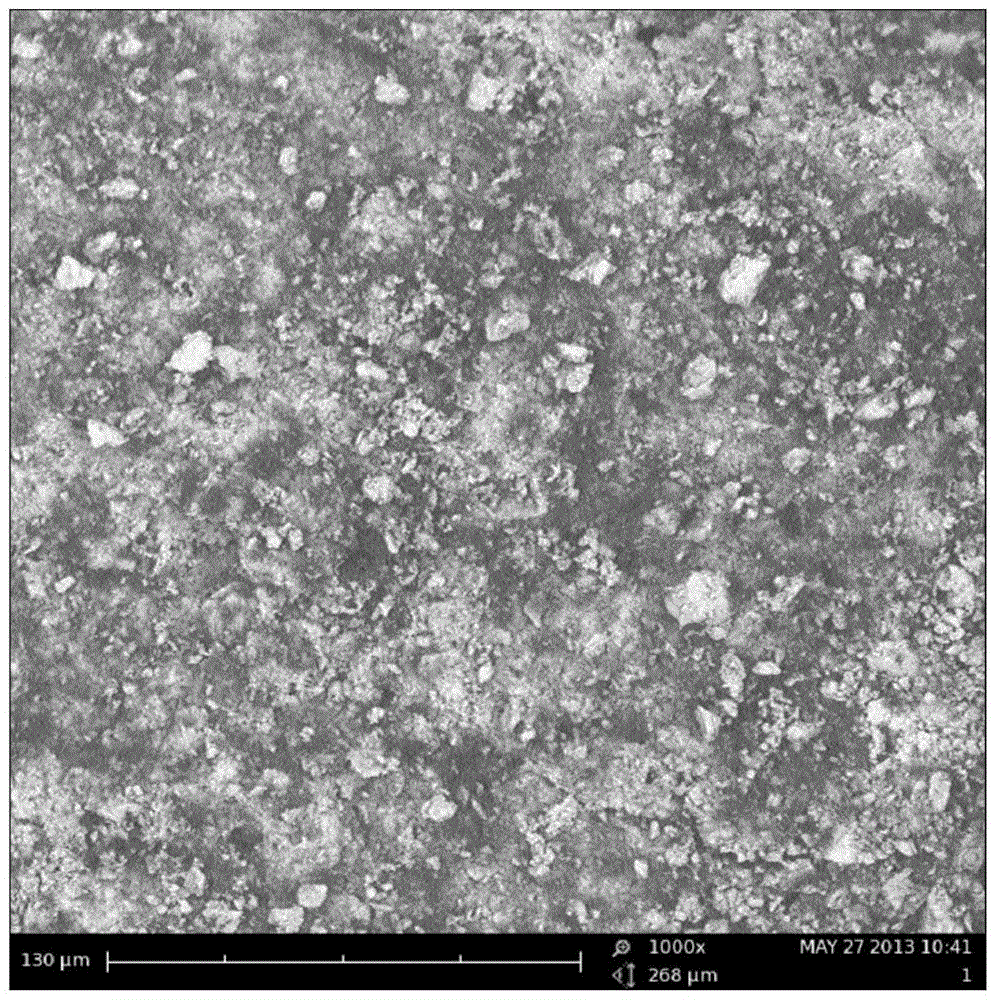

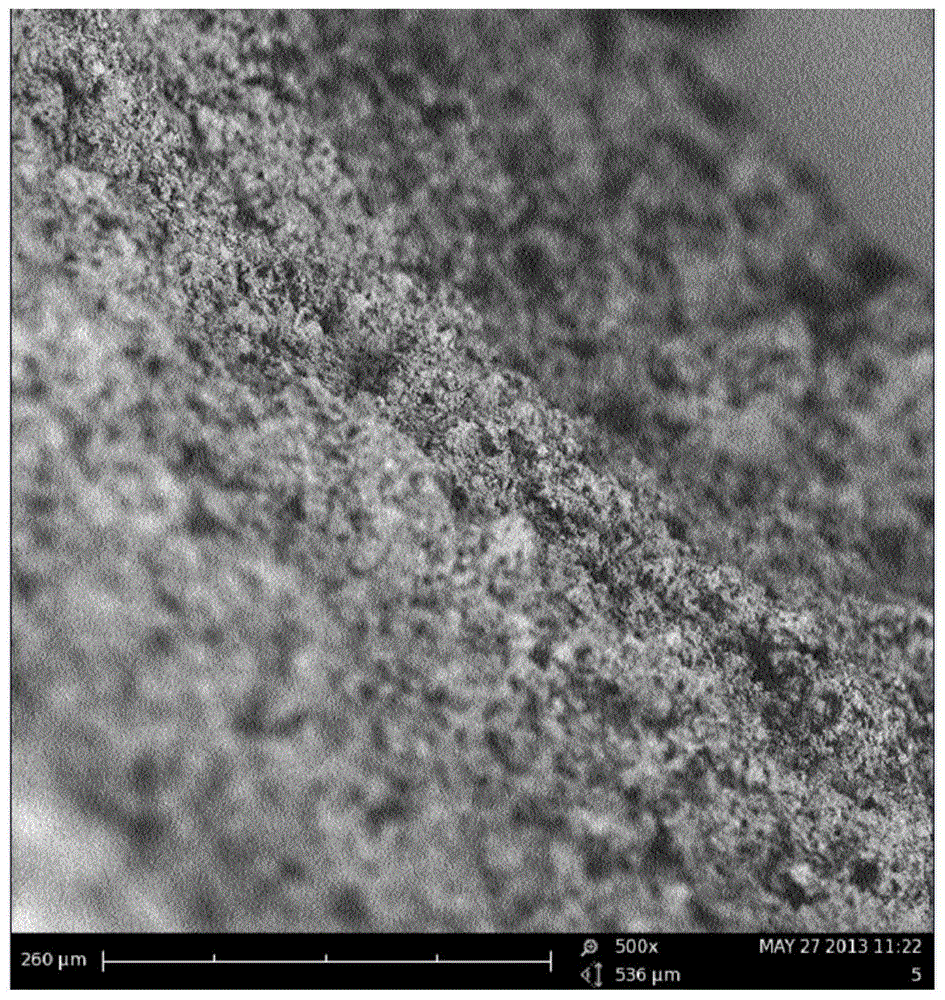

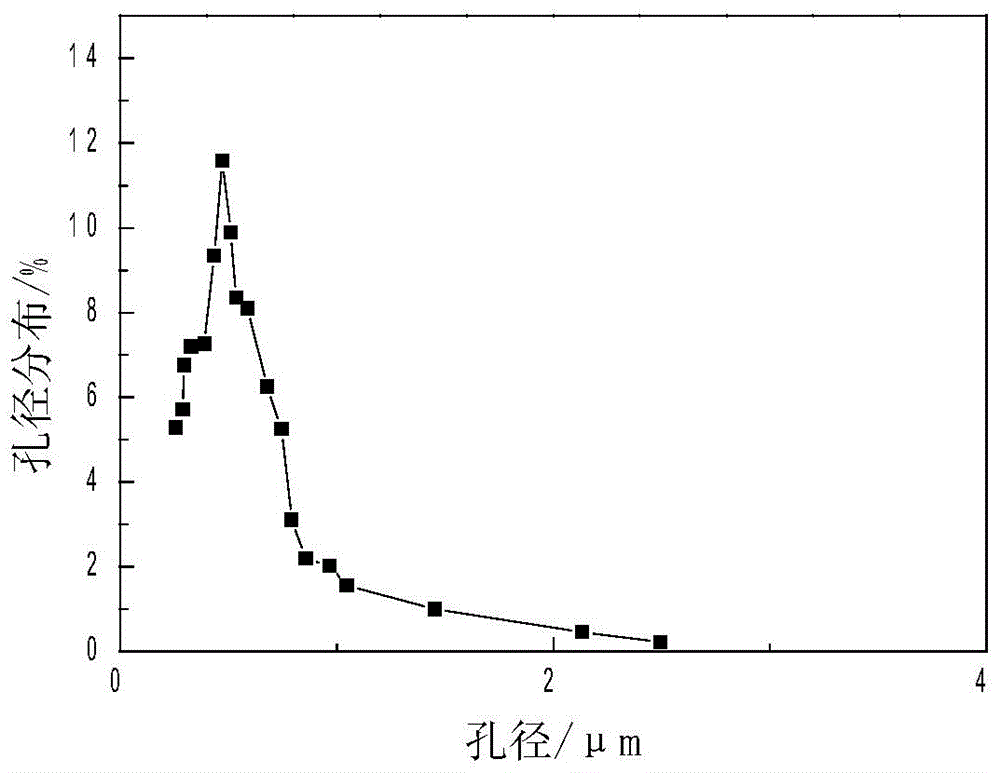

Image

Examples

Embodiment 1

[0037] A composite ion-adsorbing carbon membrane, which is made of 15 parts of modified zeolite fine powder, 20 parts of modified medical stone fine powder, 10 parts of diatomite fine powder as base material, and 30 parts of activated carbon fiber as pore-forming agent , 10 parts of humic acid as a modifier, 5 parts of aluminum dihydrogen phosphate as a binder, through mechanical mixing, banburying, pressing, and low-temperature firing, a network void-like film with a thickness of 0.3 mm is formed.

[0038] The preparation method of composite ion adsorption carbon film of the present invention is as follows:

[0039]The first step is to process the natural zeolite into 150-200 mesh fine powder, and then use 0.8-1.0mol / L NaCl solution for water bath modification. The amount of NaCl solution in the water bath requires 25mL of NaCl solution per 1g of fine powder. The temperature is 70-75°C, and the water bath time is 2.5 hours; then rinse and filter with clean water, and then dry...

Embodiment 2

[0051] A composite ion-adsorbing carbon membrane, which is made of 10 parts of modified zeolite fine powder, 25 parts of modified medical stone fine powder, 5 parts of diatomite fine powder as base material, and 35 parts of activated carbon fiber as pore-forming agent , 10 parts of humic acid as a modifier, 5 parts of aluminum dihydrogen phosphate as a binder, through mechanical mixing, banburying, pressing, and low-temperature firing, a network void-like film with a thickness of 0.5 mm is formed.

[0052] The preparation method of composite ion adsorption carbon film of the present invention is as follows:

[0053] The first step is to process the natural zeolite into 150-200 mesh fine powder, and then use 0.8-1.0mol / L NaCl solution for water bath modification. The amount of NaCl solution in the water bath requires 25mL of NaCl solution per 1g of fine powder. The temperature is 70-75°C, and the water bath time is 2.5 hours; then rinse and filter with clean water, and then dry...

Embodiment 3

[0065] A composite ion-adsorbing carbon membrane, which is made of 20 parts of modified zeolite fine powder, 15 parts of modified medical stone fine powder, 15 parts of diatomite fine powder as base material, and 35 parts of activated carbon fiber as pore-forming agent , 10 parts of humic acid as a modifier, 5 parts of aluminum dihydrogen phosphate as a binder, after mechanical mixing, banburying, pressing, and low-temperature firing, a network void-like film with a thickness of 0.7 mm is formed.

[0066] The preparation method of composite ion adsorption carbon film of the present invention is as follows:

[0067] The first step is to process the natural zeolite into 150-200 mesh fine powder, and then use 0.8-1.0mol / L NaCl solution for water bath modification. The amount of NaCl solution in the water bath requires 25mL of NaCl solution per 1g of fine powder. The temperature is 70-75°C, and the water bath time is 2.5 hours; then rinse and filter with clean water, and then dry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com