Water-spraying nozzle

A water-spraying sprinkler and sprinkler technology, which is applied in the directions of injection devices, injection devices, liquid injection devices, etc., can solve the problems of not being able to reduce the working load of the operating lever, material costs, and increase in manufacturing costs, so as to increase the workload and reduce Effect of Workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 approach >

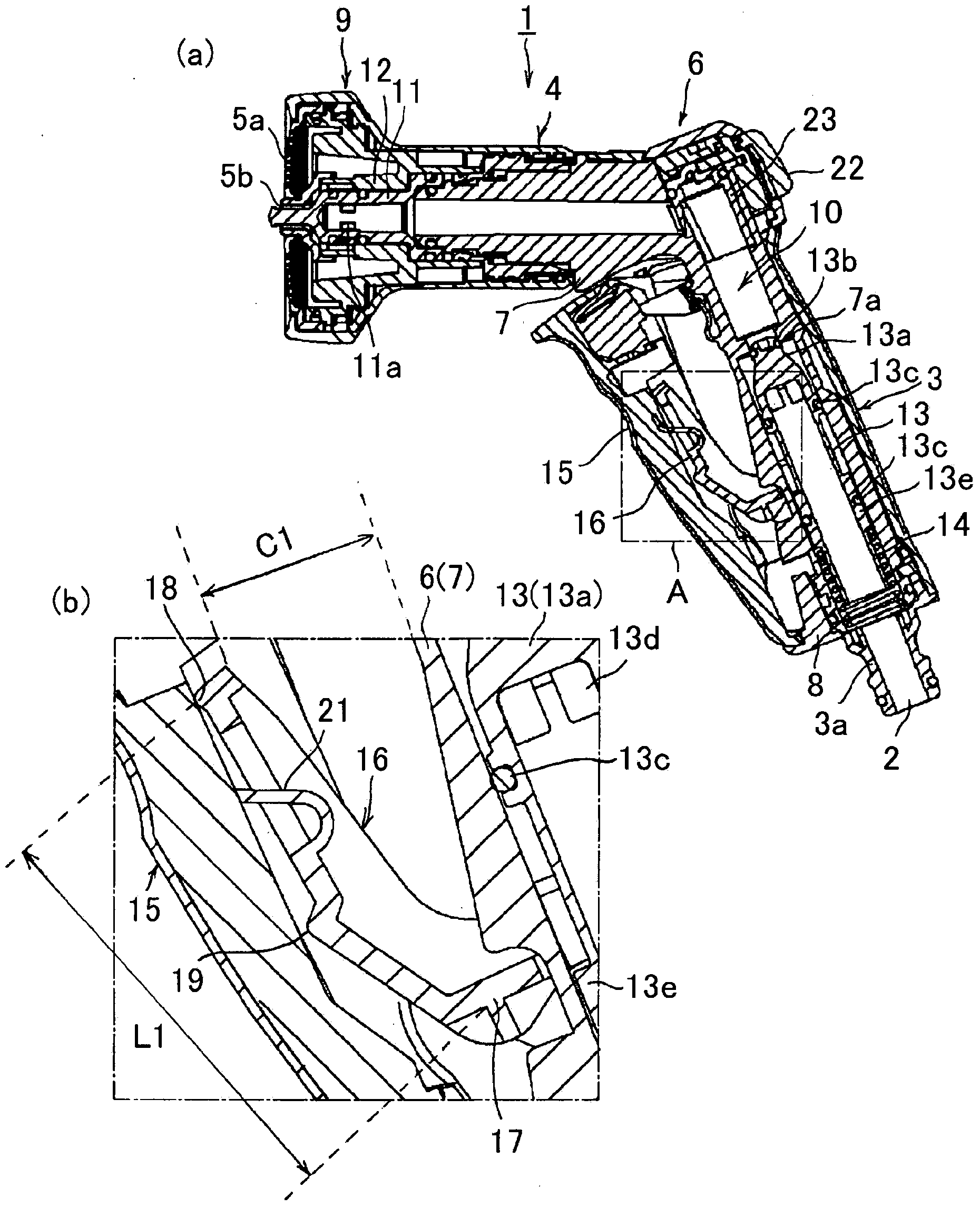

[0146] In the first embodiment, the first point of force portion 18 and the second point of force portion 19 are provided on the relay lever 16, but it is also possible to set more than three point of force portions with different distances from the fulcrum portion 17. When the lever 15 is gripped from the water-stop position to the fully open position, it abuts against the operating lever 15 sequentially from the point of force farthest from the fulcrum 17 .

[0147] In addition, the arm extending upward of the relay lever 16 may also be formed into a curved shape convex forward, and when the operating lever 15 is gripped from the water stop position to the fully open position, the point of force abutting the operating lever 15 will be reduced. The portion changes continuously from the anterior end to the proximal end of the arm.

[0148] In addition, in the first embodiment, only the section from the second force point portion 19 to the fulcrum portion 17 may be formed in a ...

no. 3 approach >

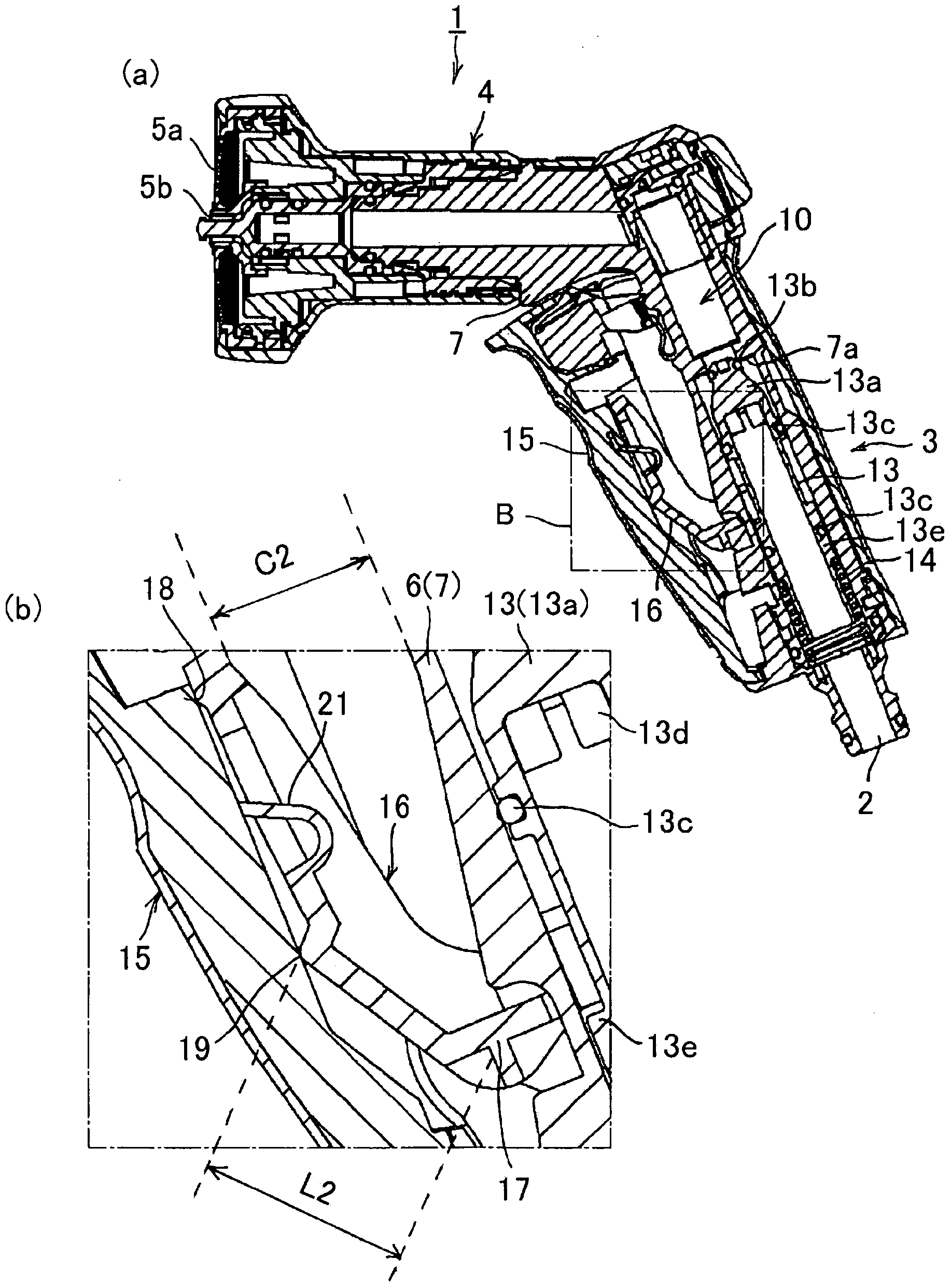

[0150] In the first embodiment, the first point of force 18 and the second point of force 19 are provided on the relay rod 16, but it is also possible to form only one point of force, instead of setting two or more points of force starting from the fulcrum portion 17. Different distances from the point of action.

[0151] In this case, at the water stop position, the action point formed at the nearest point of the fulcrum 17 abuts against the on-off valve core. The action point portions come into contact with the on-off valve body in order from the action point portion close to the fulcrum portion 17 .

[0152] According to this, similarly to the first embodiment, the workload of the operation lever 15 can be effectively reduced, and the on-off valve can be effectively opened and closed.

[0153]

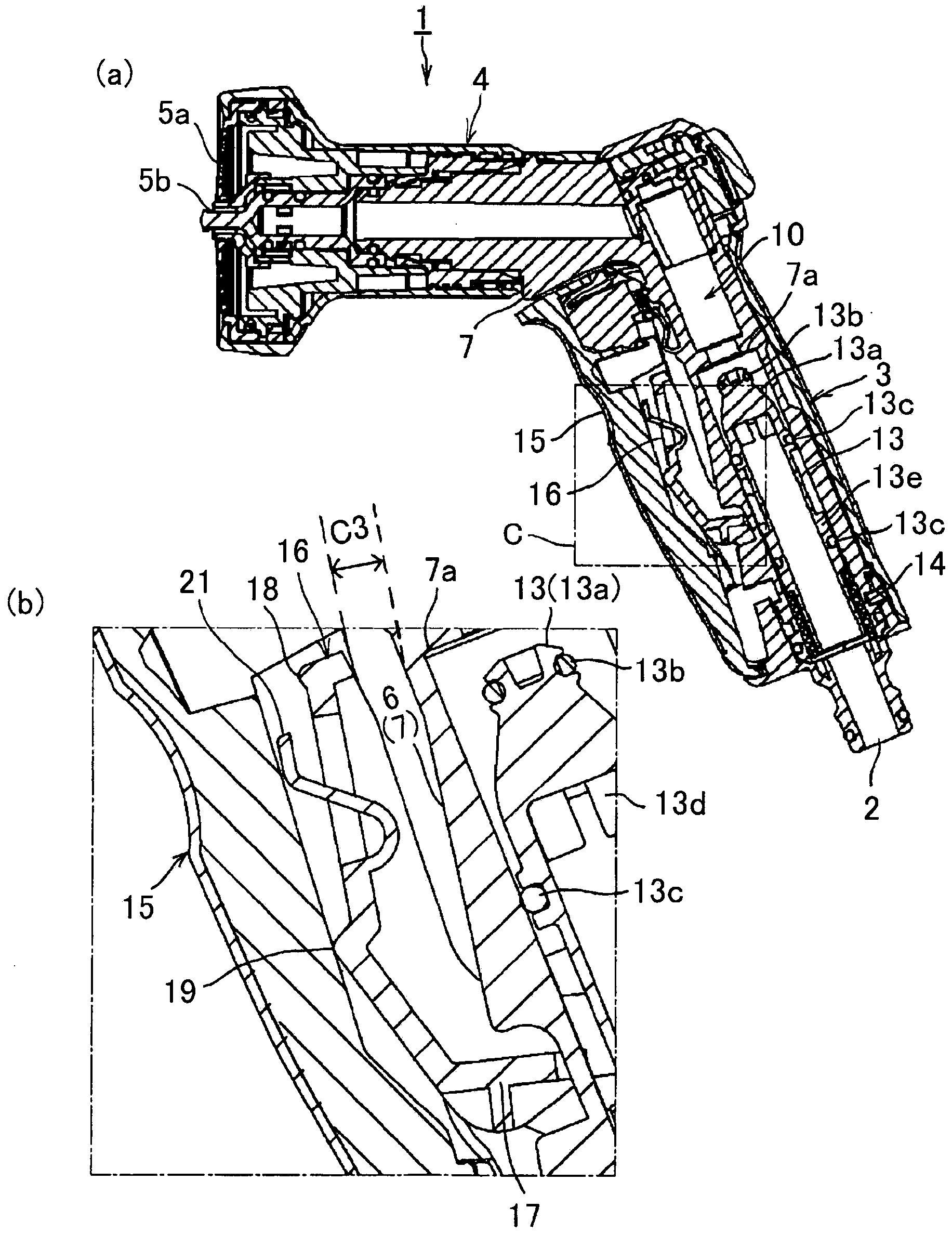

[0154] In the first embodiment, the lower end of the operating rod 15 is used as a fixed end, and the upper end is used as a free end. However, the upper end of the operating rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com