Naked-eye 3D glass plate and manufacturing method thereof

A manufacturing method and glass substrate technology, applied in optical components, optics, instruments, etc., can solve problems such as weak three-dimensional effect and inability to achieve dynamic effects, and achieve strong three-dimensional effect, continuous dynamic effect, and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

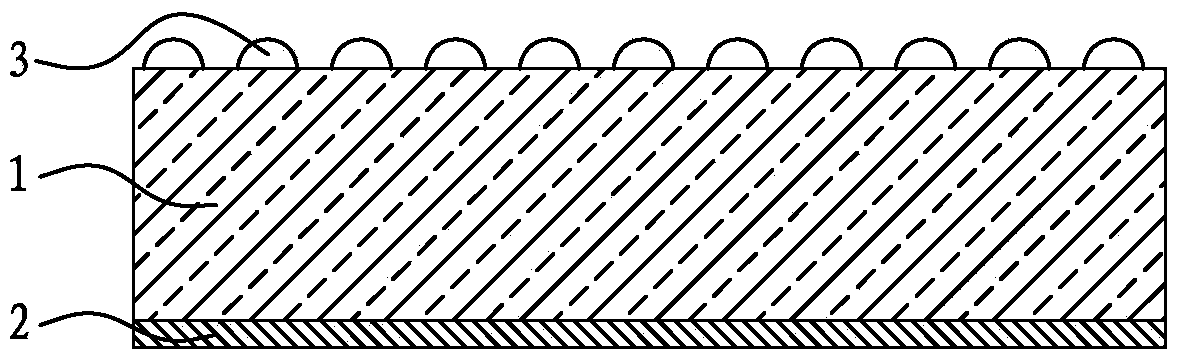

[0042] A method for making a naked-eye 3D glass plate, comprising the steps of:

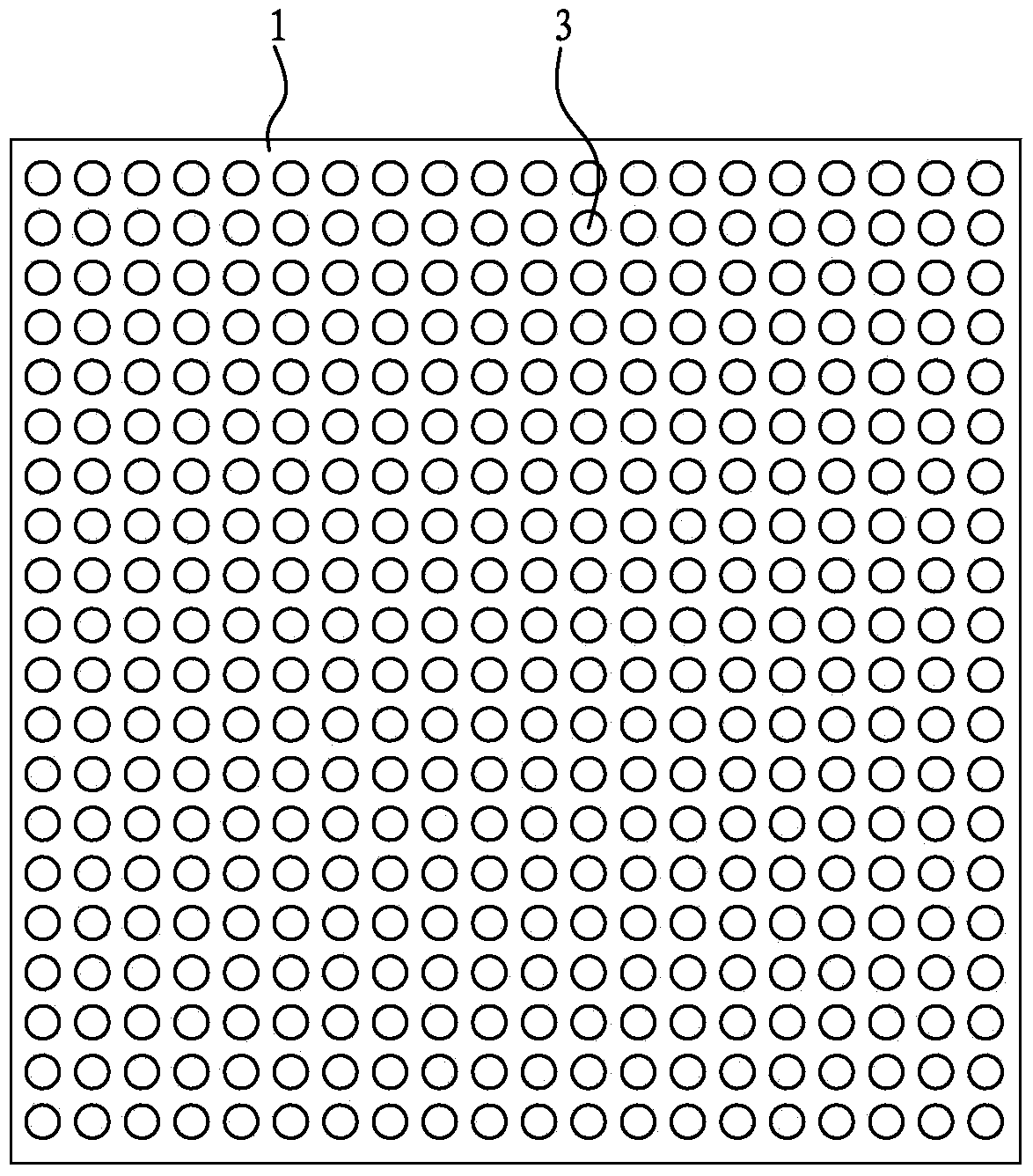

[0043] 1) Clean the surface of the transparent and qualified glass substrate 1, and then screen-print the transparent colloidal liquid UV varnish on the surface of the glass substrate with a silk machine to form a plurality of transparent circular droplets of equal size and regularly arranged;

[0044] 2) Put the screen-printed glass substrate 1 into an oven, and bake in an oven at a temperature of 100-150°C for 10-15 minutes. After drying, the liquid beads solidify and harden, forming solid bumps 3;

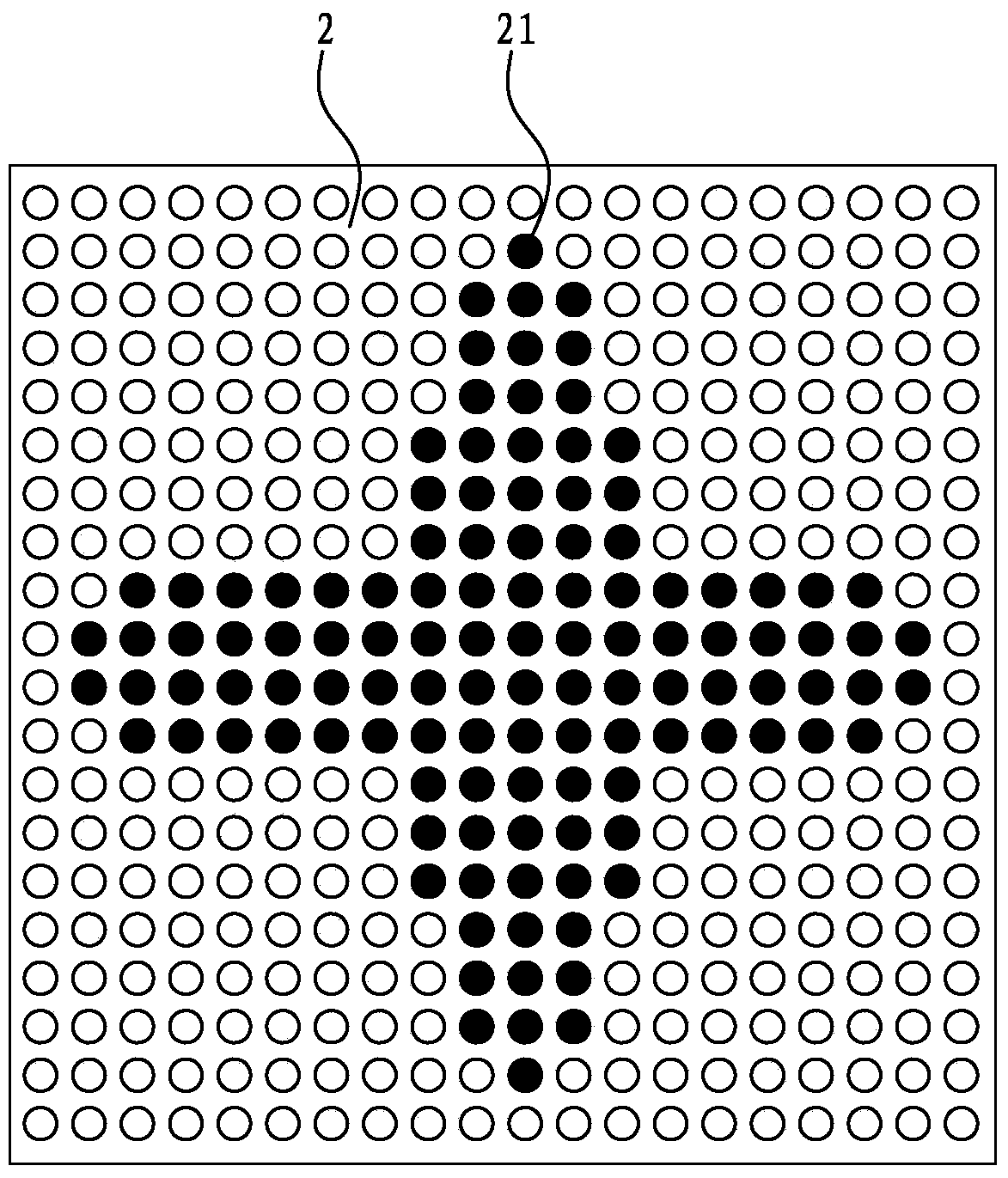

[0045] 3) Design a pattern corresponding to the structure of the bump 3, the pattern is formed by arranging a plurality of color points 21 corresponding to the bump 3, and the projection surface of the color point 21 and the bump 3 on the surface of the glass substrate 1 is equal in size and one-to-one correspondence;

[0046] 4) Print the pattern on the bottom surface of the glass substrate 1 wit...

Embodiment 2

[0048] 1) Clean the surface of the transparent and qualified glass substrate 1, and screen-print UV varnish onto the surface of the glass substrate 1 with a screen printing machine to form a plurality of transparent circular droplets of equal size and regularly arranged;

[0049] 2) Put the screen-printed glass substrate 1 for 2 hours to dry naturally, and the liquid beads solidify and harden after drying to form solid bumps 3;

[0050] 3) Design a pattern corresponding to the bump 3, the pattern is formed by arranging the color dots 21 corresponding to the bump 3, the projection planes of the color points 21 and the bump 3 on the surface of the glass substrate 1 are equal in size and one by one correspond;

[0051] 4) Print the pattern on a piece of plastic film, and paste the pattern-printed plastic film on the bottom surface of the glass substrate 1 . The side with the pattern faces the glass substrate 1 and the color points 21 of the pattern must correspond to the positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com