Detection device and detection method for inner part of small-opening and large-inner-cavity product

An internal detection and product technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of difficulty in detection, prone to misjudgment, prone to misalignment, etc., to achieve high detection accuracy, high detection efficiency, and not easy to make mistakes Judgment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present application is further described in conjunction with the following examples.

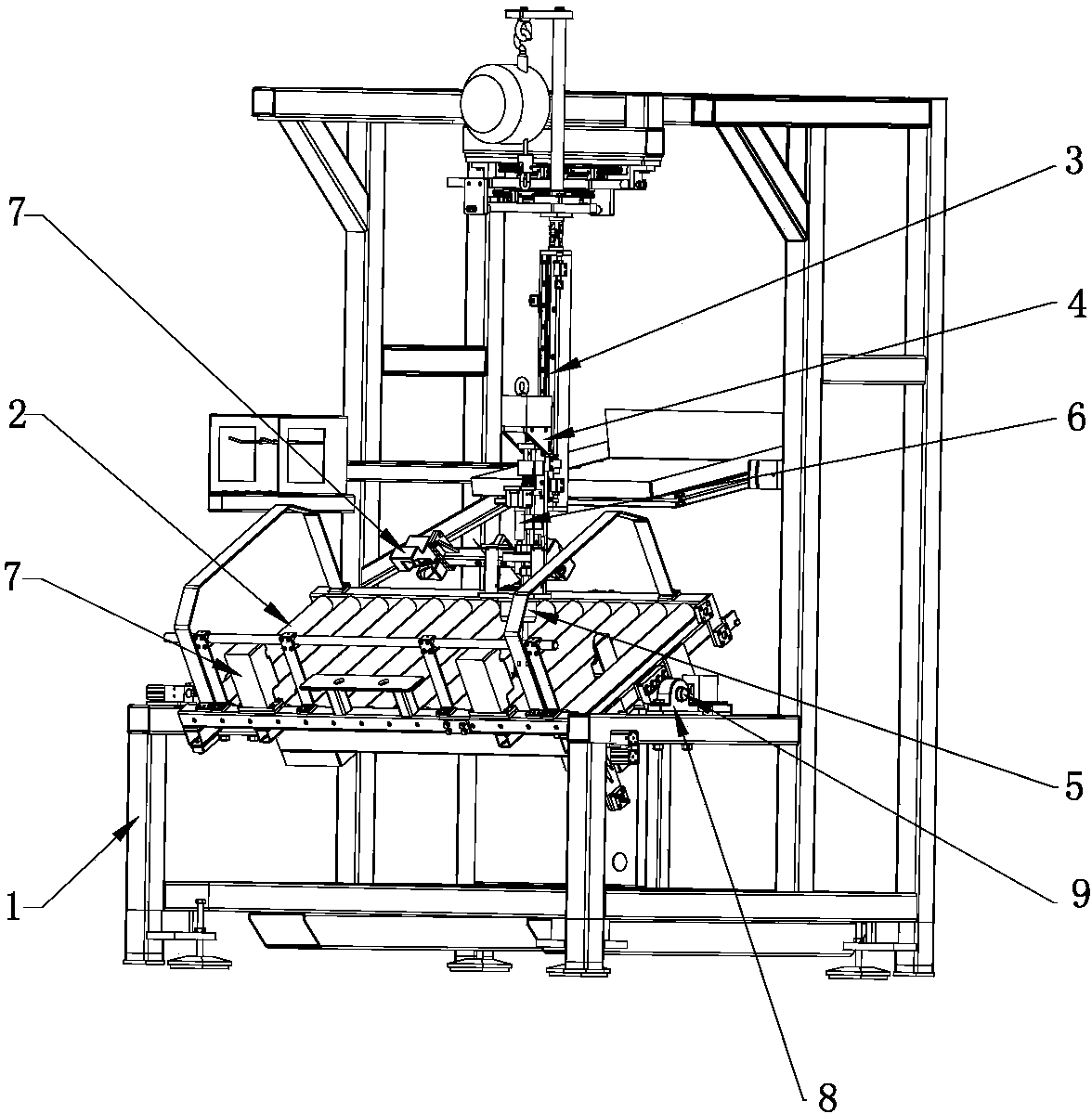

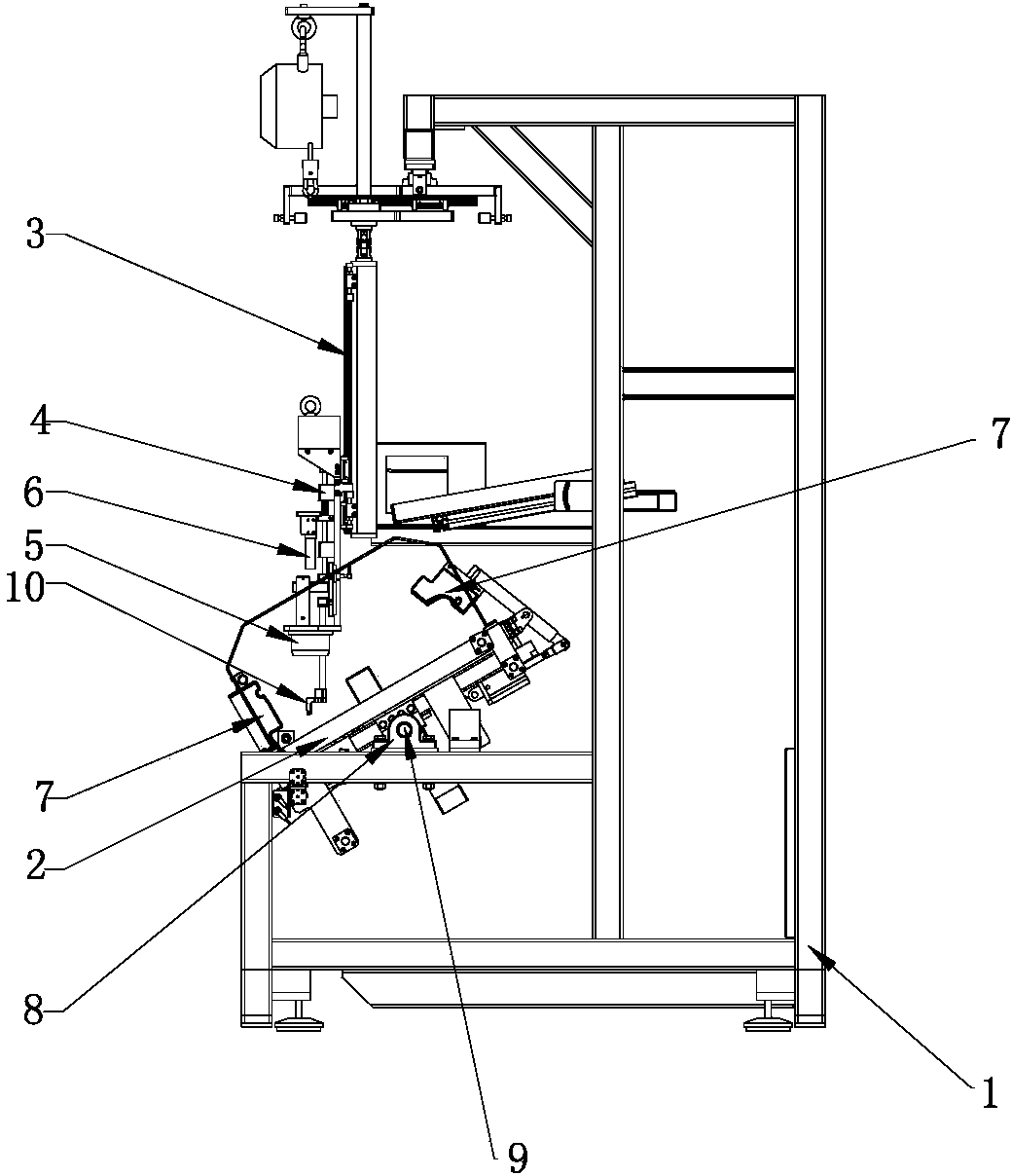

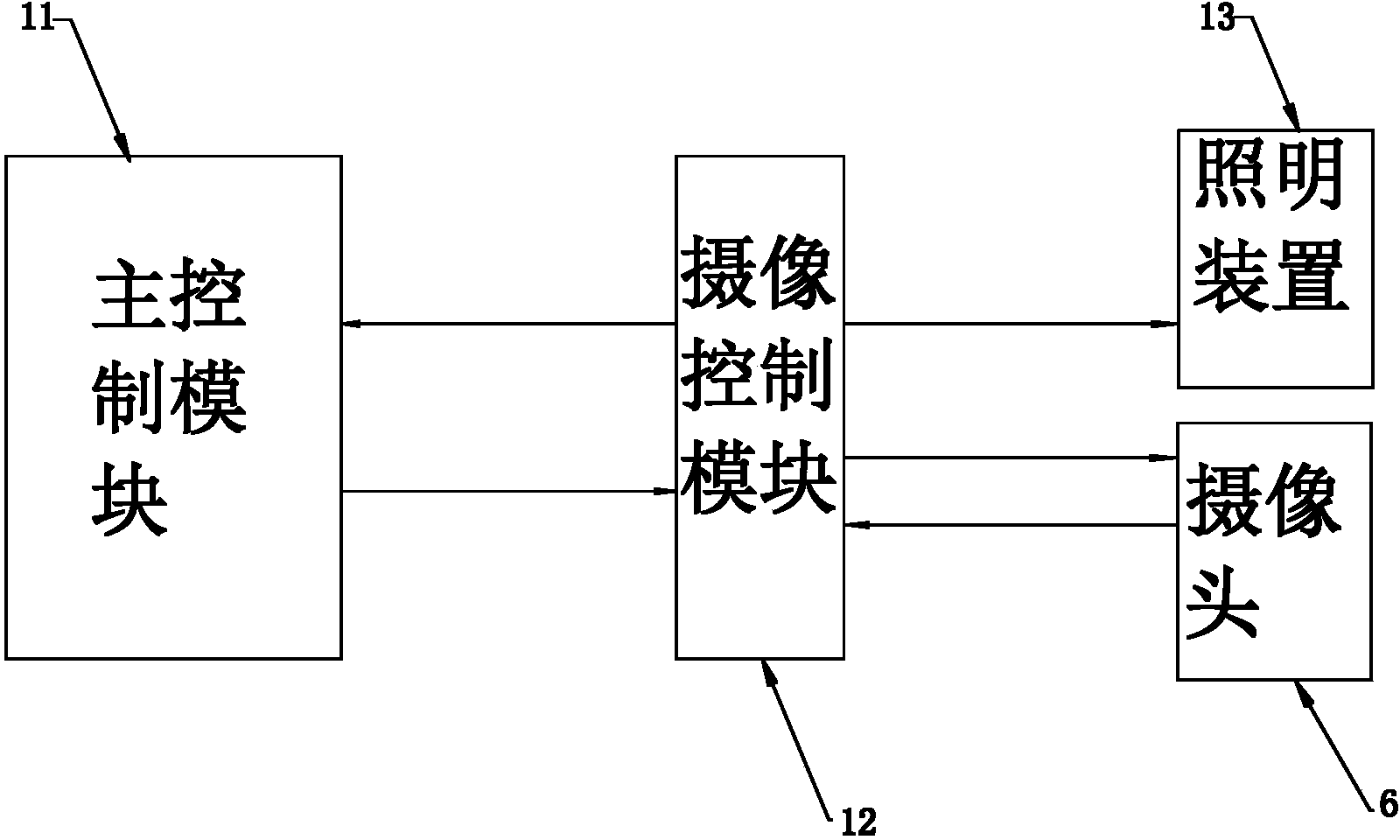

[0028] A specific implementation of the internal detection device of a product with a small opening and a large inner cavity in the present application, such as Figure 1 to Figure 3 As shown, it includes: a main control module 11, a fixed frame 1 and a detection table 2 arranged on the fixed frame 1, a detection frame is arranged above the detection table 2, and the detection frame includes a detection slide rail 3 and can be moved along the detection slide rail. 3 A reciprocating detection robot arm 4, the detection robot arm 4 includes a positioning device and a camera device, the positioning device includes a first positioning member 5 that abuts against the opening of the product under test during detection, and the first positioning member is just able to A cylinder inserted into the product opening, the top of the cylinder has an abutting block with a diameter larger than t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com