Single prism group

A single prism and prism technology, applied in installation, optics, measuring devices, etc., can solve the problems of inconvenient adjustment of prism alignment, inability to achieve left-right fine-tuning of single-prism groups, and achieve auxiliary alignment fine-tuning, high adjustment accuracy, and improved detection. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

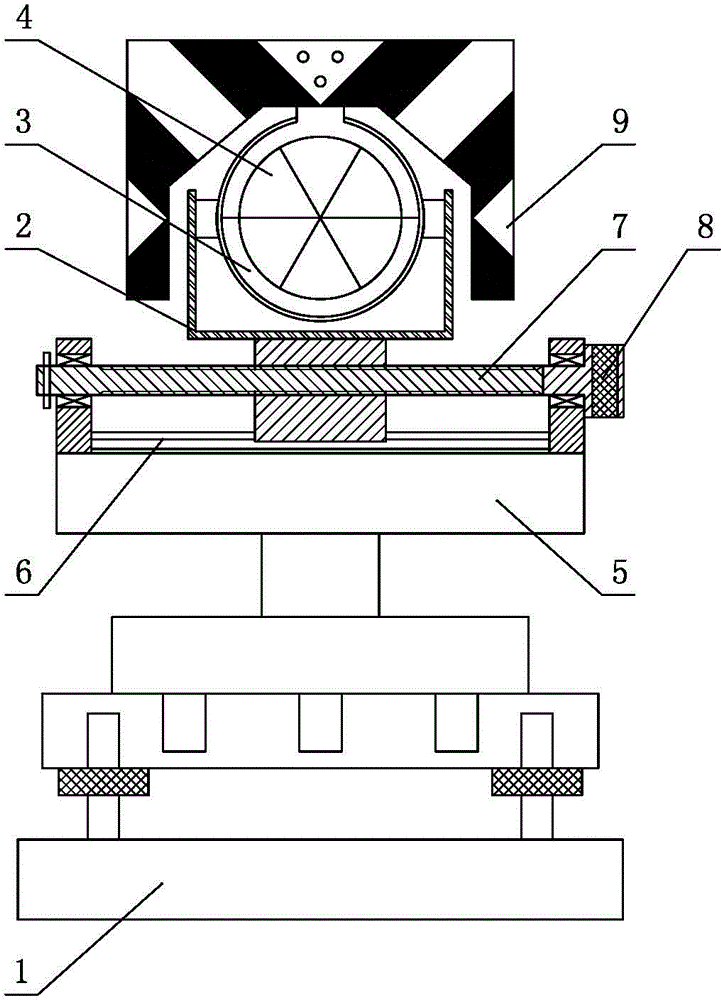

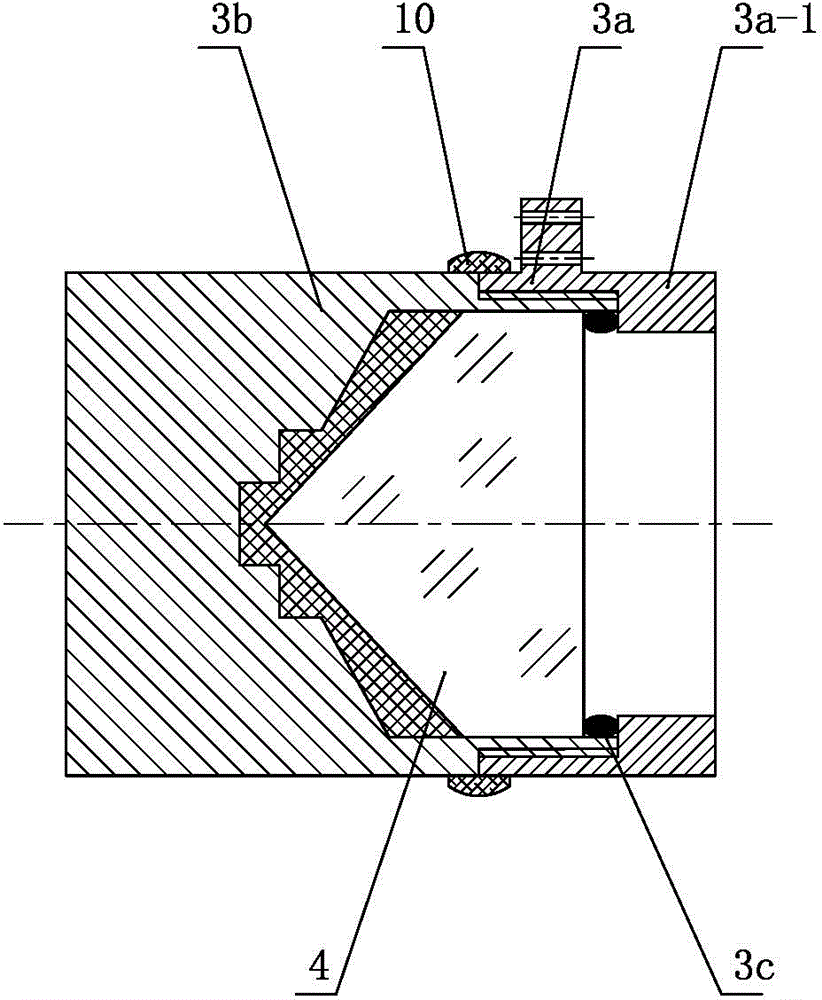

[0015] like figure 1 As shown, the single prism group includes a base 1, a bracket 2 and a prism assembly; the prism assembly includes a prism frame 3 and a prism 4 embedded in the prism frame 3, and the prism frame 3 and the prism 4 are coaxially arranged; the base 1 A horizontal workbench 5 is connected to the top, and a horizontal slide rail 6 is laid on the horizontal workbench 5. A slide rail groove is provided on the bracket 2 corresponding to the horizontal slide rail 6; the two ends of the screw 7 are supported on the horizontal workbench by bearings. 5 , the lead screw 7 and the horizontal slide rail 6 are arranged parallel to each other, the lead screw 7 runs through the support 2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com