A block hole type graphite reboiler and its manufacturing method

A manufacturing method and a reboiler technology are applied to the block-hole graphite reboiler and the manufacturing field thereof to achieve the effects of improving sealing effect, good corrosion resistance and improving permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

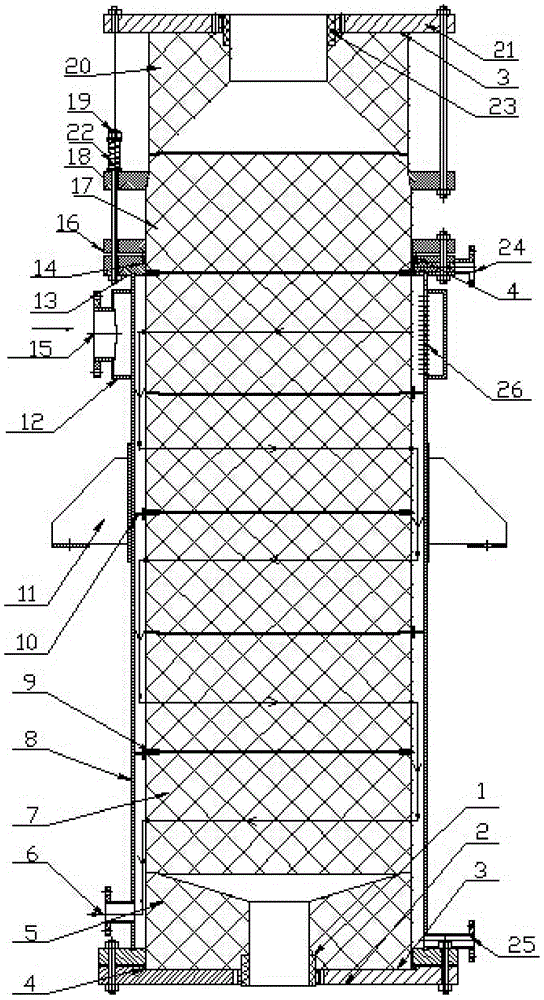

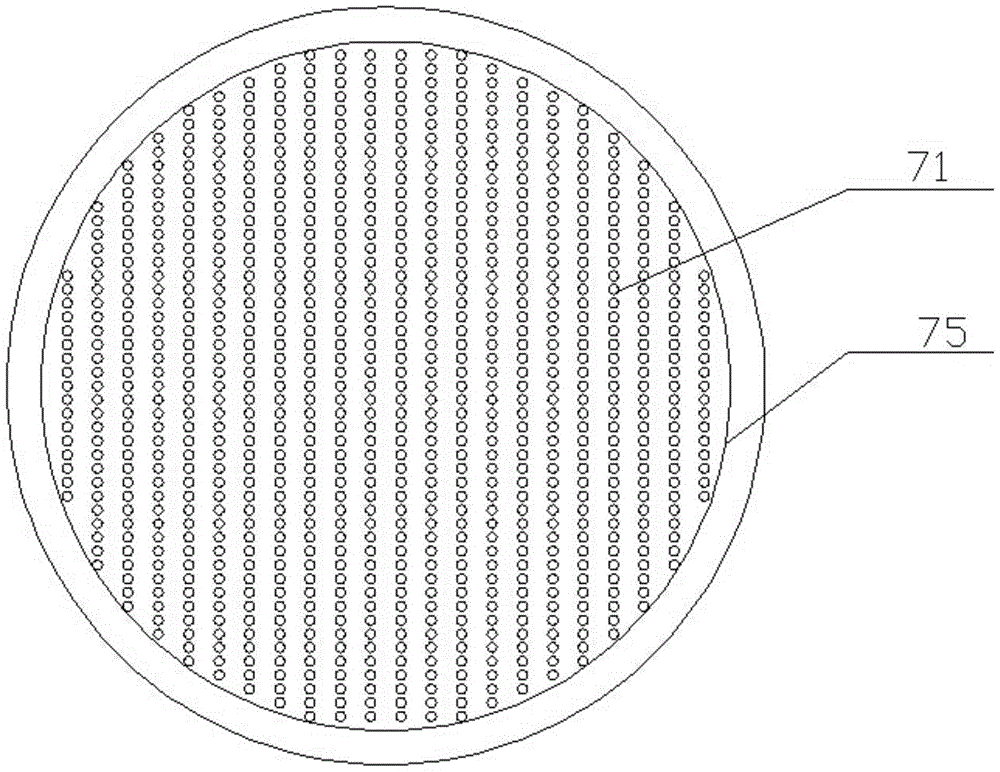

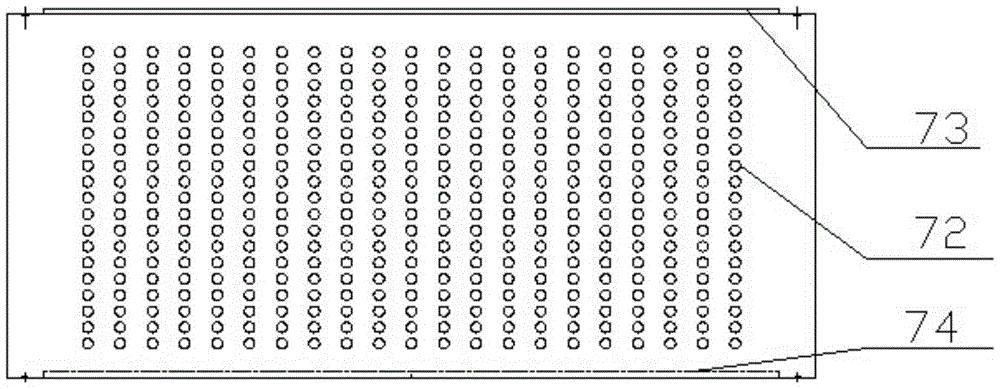

Embodiment 1

[0026] Embodiment 1 of the present invention: a kind of block hole type graphite reboiler, as attached Figure 2-5 Shown, this graphite reboiler comprises graphite block 7, and this graphite block 7 is cylinder structure, is evenly provided with a plurality of material holes 71 that run through the whole cylinder upper and lower surfaces inside graphite block 7, and its inside From left to right, there are evenly arranged a plurality of steam holes 72 passing through the side of the cylinder, and the material holes 71 and the steam holes 72 are arranged alternately and do not communicate with each other. The hole diameter of the material hole 71 and the steam hole 72 is 8-22mm, the wall thickness between the material hole 71 and the steam hole 72 is 3-8mm, the wall thickness between the material holes 71 is 3-8mm, and the wall thickness between the steam holes 72 is 3-8mm. The distance from the material hole 71 outer envelope 75 to the graphite block 7 outer ring body is 20-5...

Embodiment 2

[0065] Embodiment 2 of the present invention: the structure of the graphite reboiler of this embodiment is the same as that of Embodiment 1, and the assembly method is also the same. The difference lies in the impregnation treatment and heat treatment of the graphite parts. In this embodiment, the graphite parts will be prepared with graphite materials: feed pipe 1, lower sealing head 5, graphite block 7, upper graphite block 17, upper sealing head 20 and The discharge pipe 23 is put into the impregnation kettle for phenolic resin impregnation treatment, the impregnation air pressure is 0.5-1.6Mpa, and the impregnation time is 12 hours, and then the impregnated graphite parts are put into the heat treatment kettle for heat treatment, heat treatment The time is 18 hours, and the heat treatment temperature is 150°C. After repeating the stain treatment and heat treatment for 2-4 times, the treated graphite parts are followed up. After impregnation and heat treatment, the strengt...

Embodiment 3

[0066]Embodiment 3 of the present invention: the structure of the graphite reboiler of this embodiment is the same as that of Embodiment 1, and the assembly method is also the same. The difference lies in the impregnation treatment and heat treatment of the graphite parts. In this embodiment, the graphite parts will be prepared with graphite materials: feed pipe 1, lower sealing head 5, graphite block 7, upper graphite block 17, upper sealing head 20 and The discharge pipe 23 is put into the impregnation kettle for phenolic resin impregnation treatment, the impregnation air pressure is 0.5-1.6Mpa, and the impregnation time is 16 hours, and then the impregnated graphite parts are put into the heat treatment kettle for heat treatment, heat treatment The time is 24 hours, and the heat treatment temperature is 190°C. After repeating the stain treatment and heat treatment for 2-4 times, the treated graphite parts are followed up. After impregnation and heat treatment, the strength...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com