Inertial pre-dedusting flue gas distributor of deduster

A technology of distributing device and dust collector, applied in the direction of combination device, separation method, dispersed particle separation, etc., can solve the problems of filter bag damage, reduce the dust removal efficiency of the bag filter, reduce the service life of the filter bag, etc. The effect of reducing the probability of breakage and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

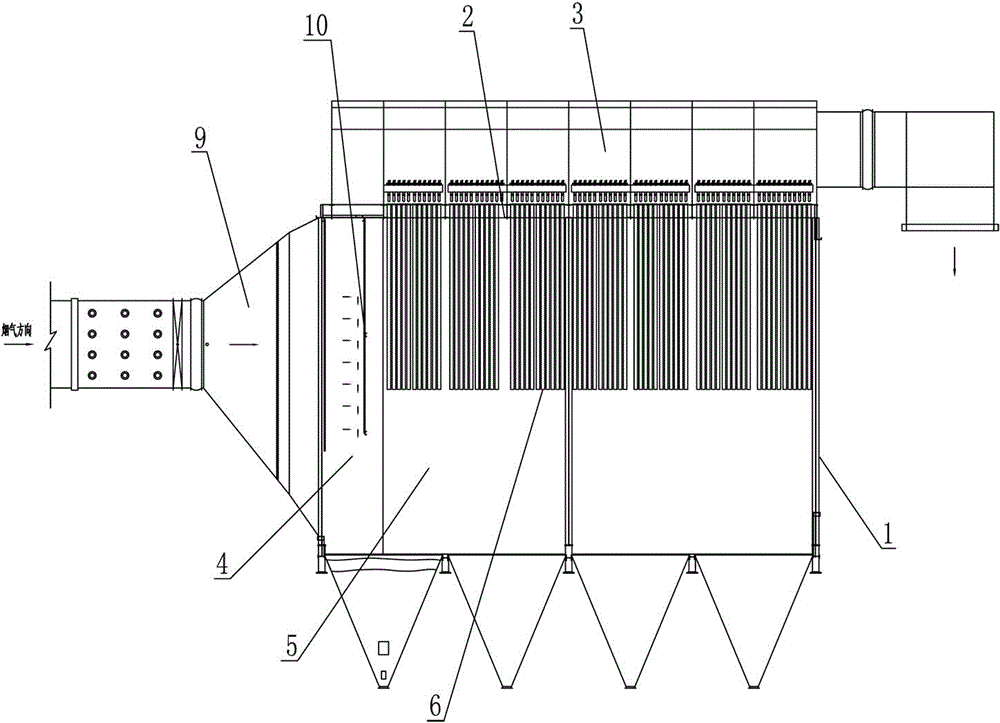

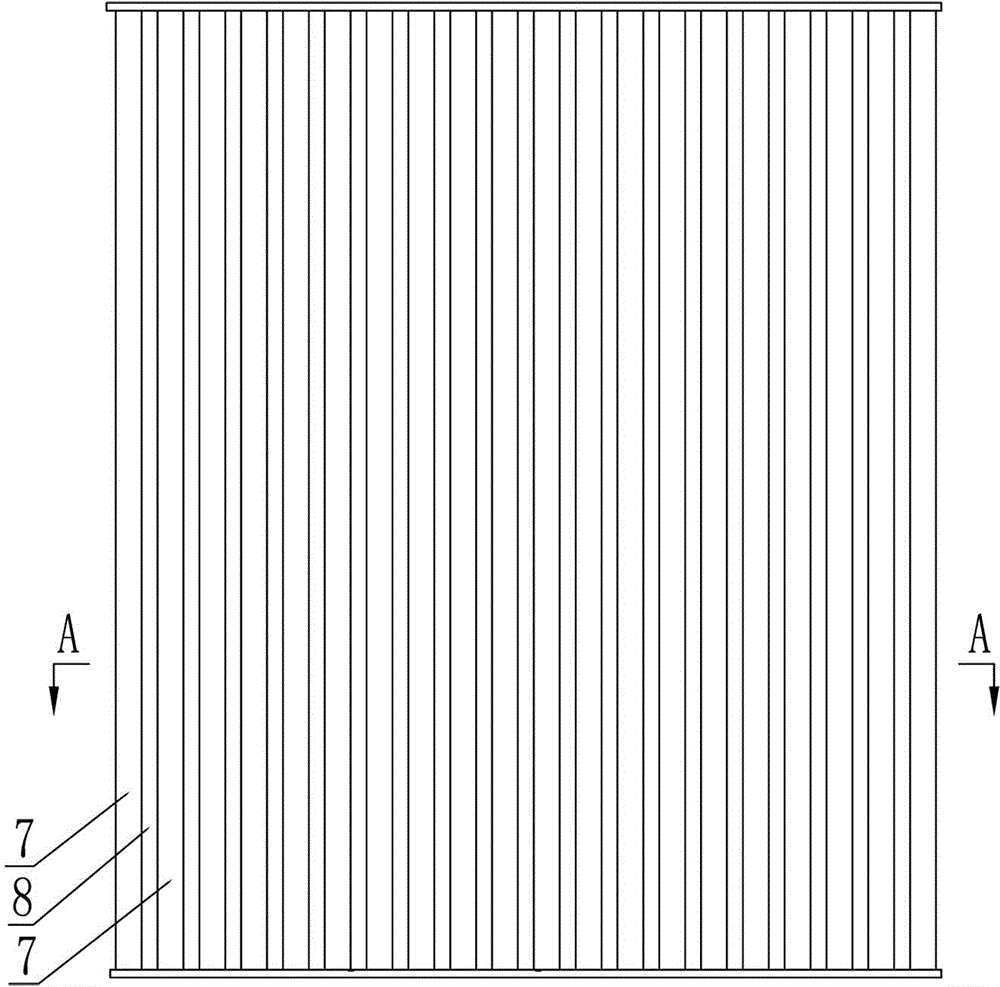

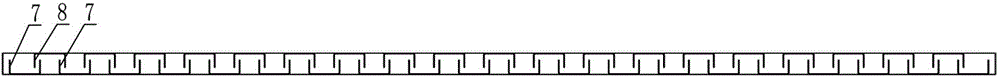

[0013] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the inertial pre-dust removal flue gas distribution device of the dust collector includes: the dust collector box 1, the dust collector box 1 is divided into an upper clean gas chamber 3 and a lower flue gas chamber by a flower plate 2, and the lower flue gas chamber It is composed of the connected pre-cleaning room 4 and the bag-cleaning room 5. On the flower plate of the bag-cleaning room 5, there are several filter bags 6 connected with the upper air-cleaning room 3. The pre-dusting room of the dust collector box 1 4 is provided with an air inlet, and the upper clean air chamber 3 is provided with an air outlet; in the pre-dust removal chamber 4, a number of flue gas pre-dust removal distribution mechanisms 10 are sequentially arranged at intervals along the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com