Manufacturing device for splicing tape roller

A technology for manufacturing devices and adhesive tapes, which is applied in the field of adhesive tape rollers, can solve the problems of slow transmission speed, poor productivity, complicated control, etc., and achieve the effect of preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

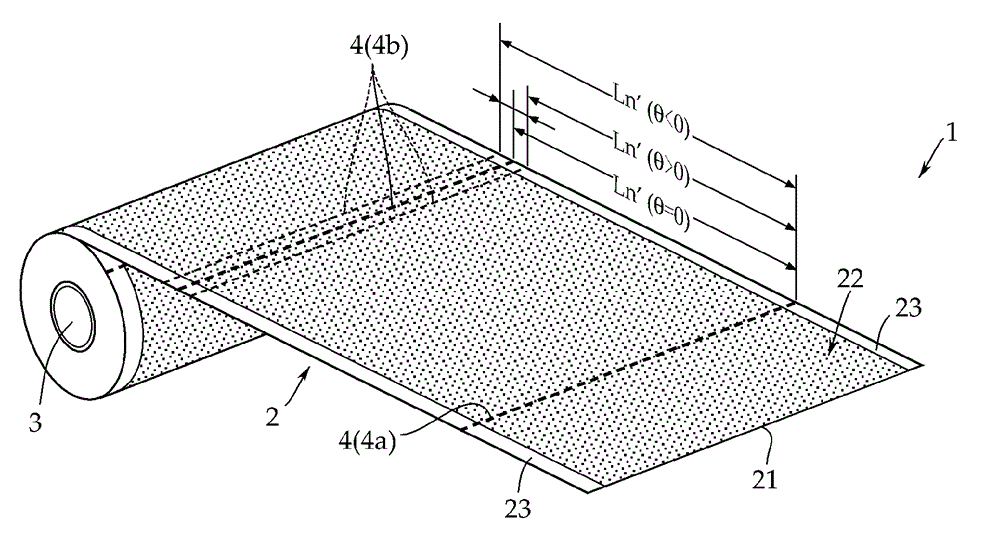

[0039] Next, embodiments of the present invention will be described with reference to the drawings, but the present invention is not limited thereto. Such as figure 1 As shown, the adhesive tape roll 1 has an adhesive tape 2 formed with an adhesive surface 22 for sweeping garbage with a base material 21, and is rolled along the roll with the adhesive surface 22 facing the front side (outside). The core 3 is wound into a roll shape.

[0040] In this example, a core made of paper such as corrugated cardboard is used for the core 3 , but a core made of synthetic resin may be used instead. Furthermore, a so-called coreless structure in which the adhesive tape roll 1 is wound without using the winding core 3 may be used, but in the present invention, the structure of the winding core 3 is arbitrary.

[0041] The tape base 21 is made of, for example, paper, and an unillustrated laminated film is provided on the back surface for reinforcement of the tape base 21 and for peeling fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com