A micro tillage machine engine and screw transmission box installation structure

A technology of screw drive and engine, which is applied in the field of micro tillage machines, can solve the problems of inconvenient selection of suitable power for micro tillage machines, complicated installation process of worm transmission box, and large space occupied by vertical engines, so as to achieve convenient obstacle crossing and compact structure , the effect of simple shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

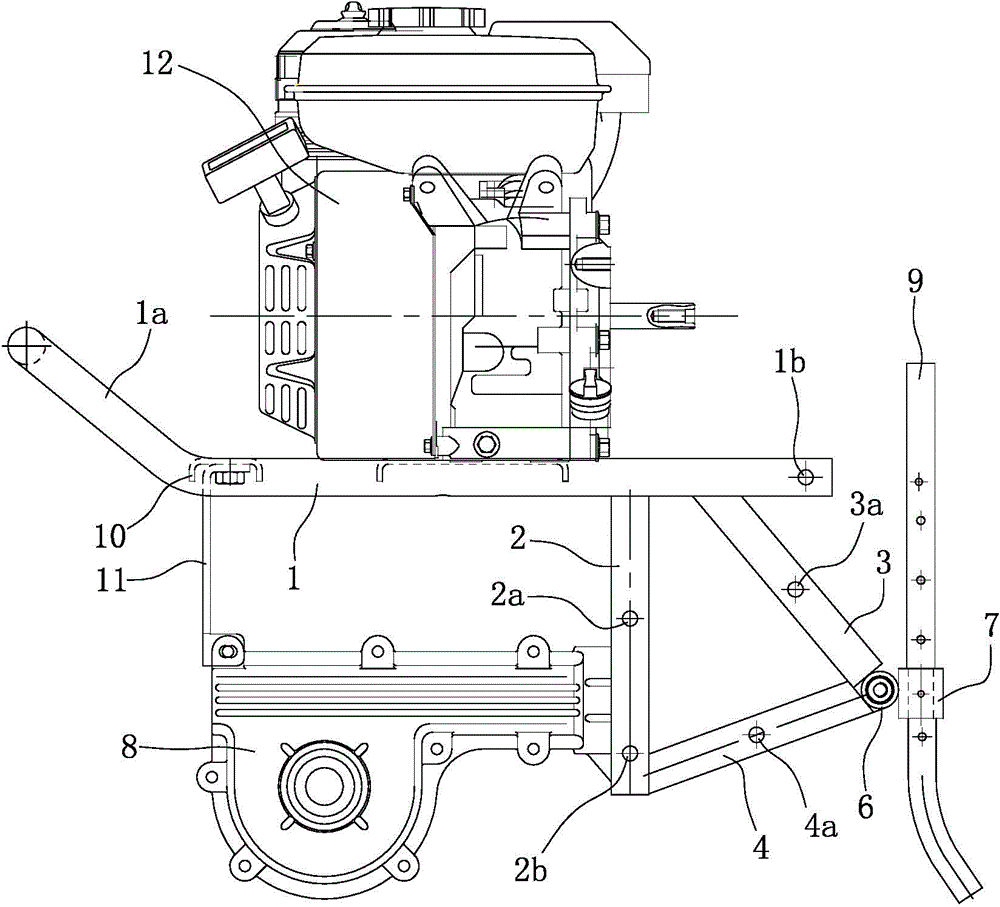

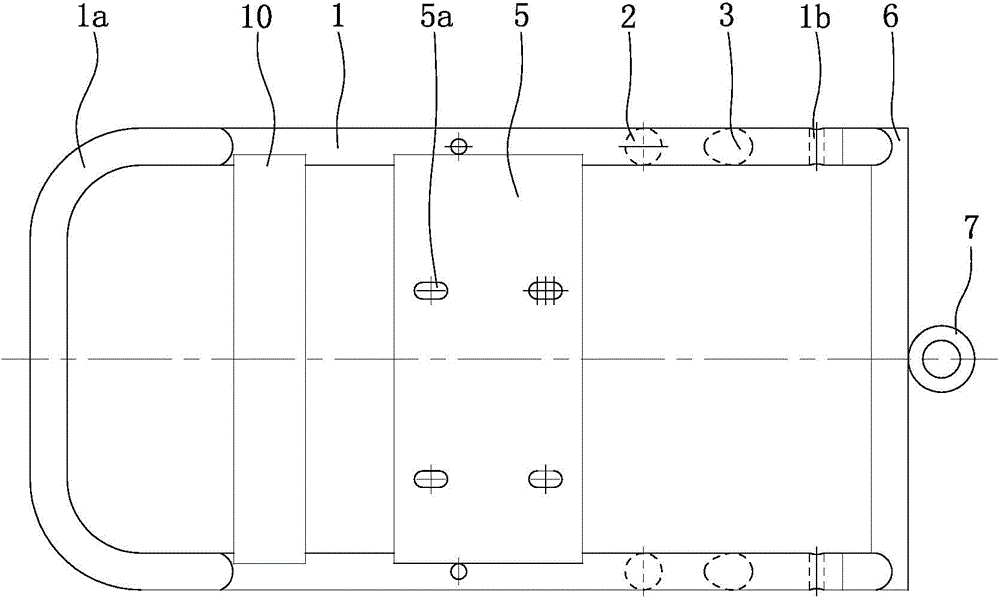

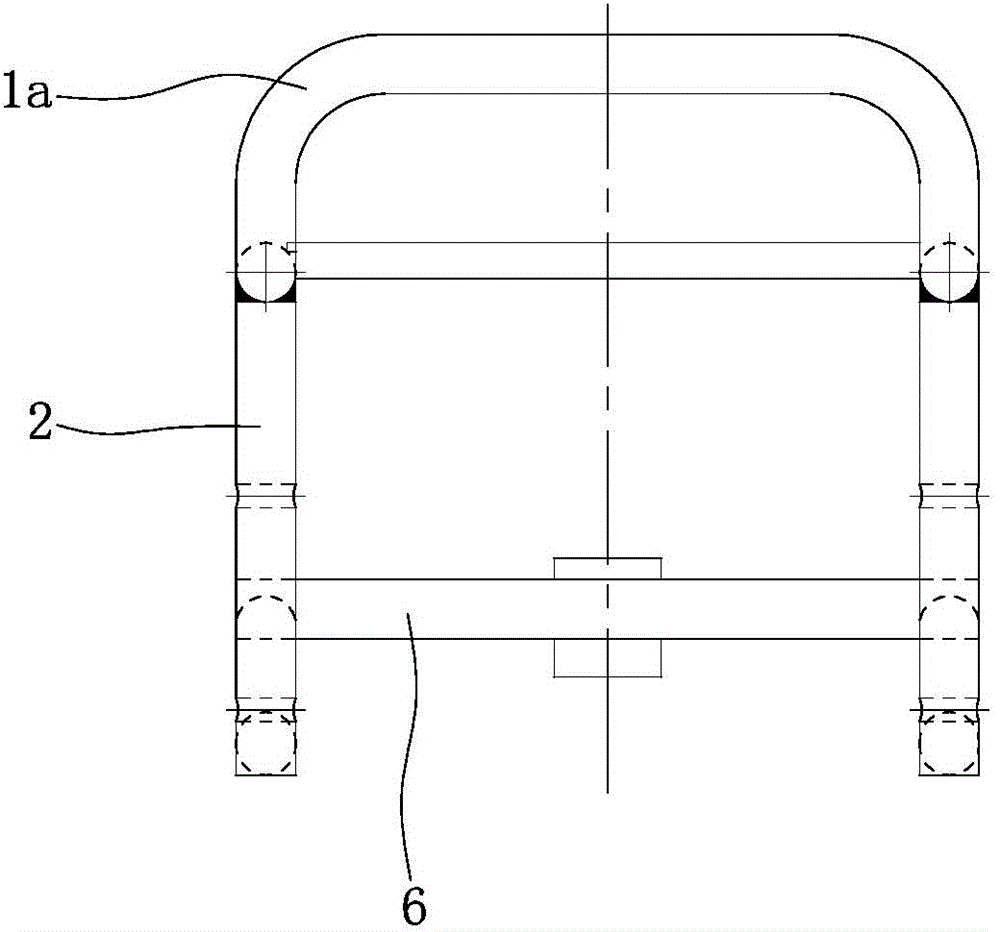

[0020] Such as figure 1 , figure 2 , image 3 As shown, the frame is composed of a main pipe 1, a standpipe 2, a first inclined pipe 3, a second inclined pipe 4, a supporting plate 5, a horizontal pipe 6 and a positioning sleeve 7 and the like. Wherein, the main pipe 1 is in the shape of a "U" with the front end closed and the rear end open, and the front end of the main pipe 1 is tilted up to form a bumper 1a, which has an included angle of 130-150° between the bumper 1a and the horizontal section of the main pipe 1 . A crossbeam 10 is arranged at the front end between the two horizontal sections of the main pipe 1. The end of the crossbeam 10 is welded to the pipe body of the corresponding horizontal section of the main pipe 1. The crossbeam 10 and the upper end of the front bracket 11 are fixed by bolts. The left and right ends of the screw drive box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com