Assembly for actuating double-acting shift cylinder of shift assembly of automatic transmission of motor vehicle

A technology of automatic transmission and shifting device, applied in the direction of transmission control, valve operation/release device, valve device, etc., can solve problems such as system damage, transmission or vehicle damage, no longer able to move, etc., and achieve structural unit price Inexpensive, compact design, anti-motion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

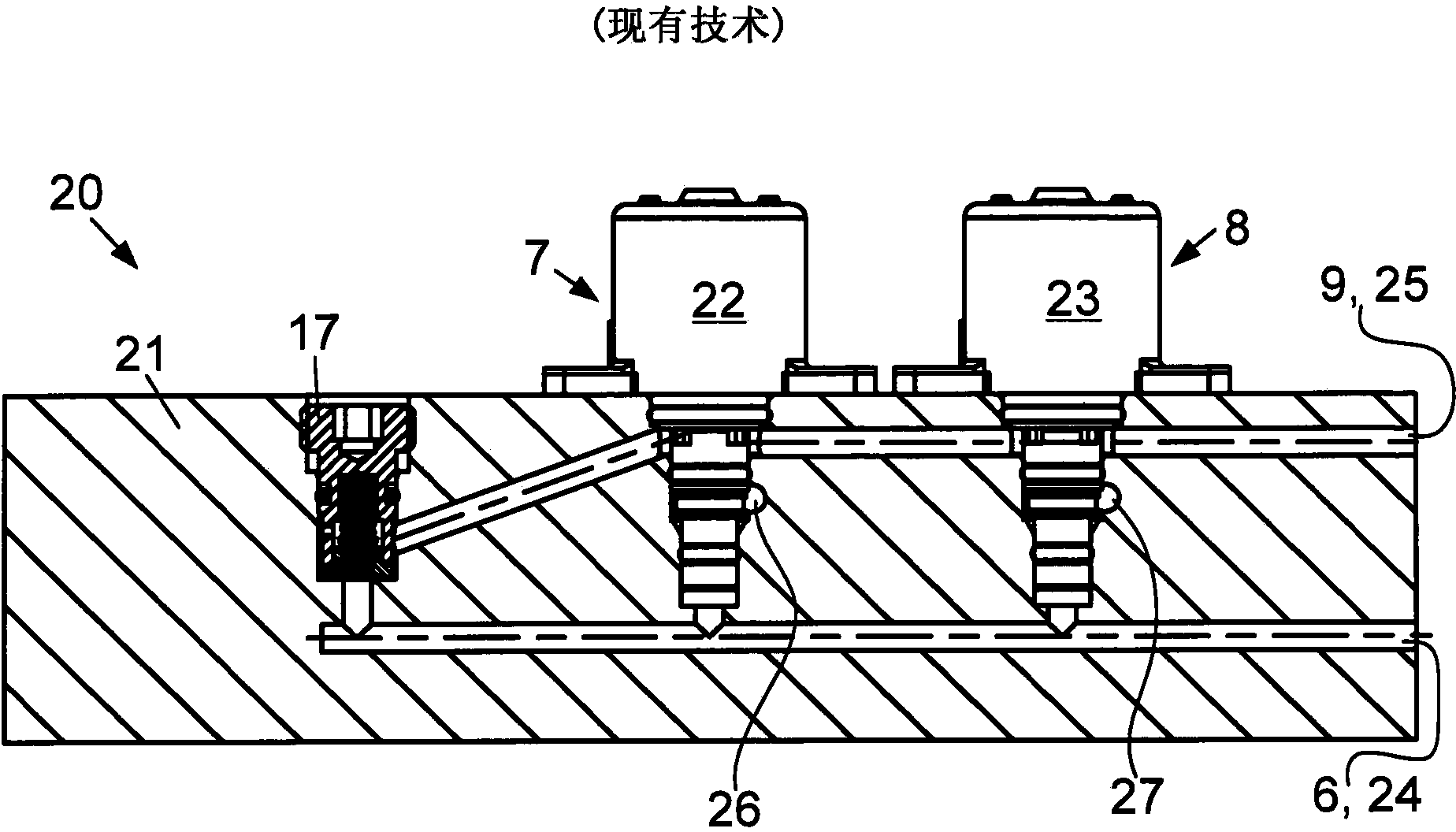

[0027] Before proceeding to a more detailed study of the present invention, a brief exposition of the prior art from which the present invention starts.

[0028] Figure 1a shows the usual control of motor vehicles in the Figure 1a The device 1 of the double-acting shift cylinder 2 of the automatic transmission not shown in the figure. The device 1 has a hydraulic fluid reservoir 3 with a hydraulic pump 5 driven by an electric motor 4 . A pressure supply line 6 is connected to the hydraulic pump 5 . The pressure supply line 6 is connected in each case to a selector valve 7 , 8 which is each configured as a 2 / 2 directional control valve. A return line 9 is connected to the switching valves 7 , 8 in each case, which leads back into the hydraulic accumulator 3 . The shift valves 7 , 8 are connected to the working chambers 10 , 11 of the shift cylinder 2 , respectively. During operation, the selector valves 7 , 8 designed as solenoid valves are switched alternately so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com