A kind of preparation method of high-voltage nickel-cobalt-manganese-lithium oxide positive electrode material

A technology of nickel-cobalt-manganese-lithium and positive electrode materials, applied in battery electrodes, electrochemical generators, circuits, etc., can solve problems such as cycle life attenuation, and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of the high-voltage nickel-cobalt-manganese-manganese lithium oxide positive electrode material of the present invention comprises the following steps:

[0024] 1) Use a high-speed mixer to uniformly mix the ternary material precursor powder, lithium carbonate powder, and oxide powder of the metal element M in proportion, and then place it in a bell furnace at a rate of 5-10°C / min in an air atmosphere Heat up, heat at 730-800°C for 4-6h, then continue to heat up to 880-980°C for constant temperature roasting for 4-8h, then cool down to room temperature with the furnace, after crushing and sieving, high-voltage nickel-cobalt-manganese-lithium oxide primary powder is obtained ;

[0025] 2) Establish coating system A: use deionized water and the salt corresponding to the coated metal element X to configure a solution for coating the metal element X; add inducer and urea to the solution, and stir at a constant speed for 0.2-1h; Add ammonia water unti...

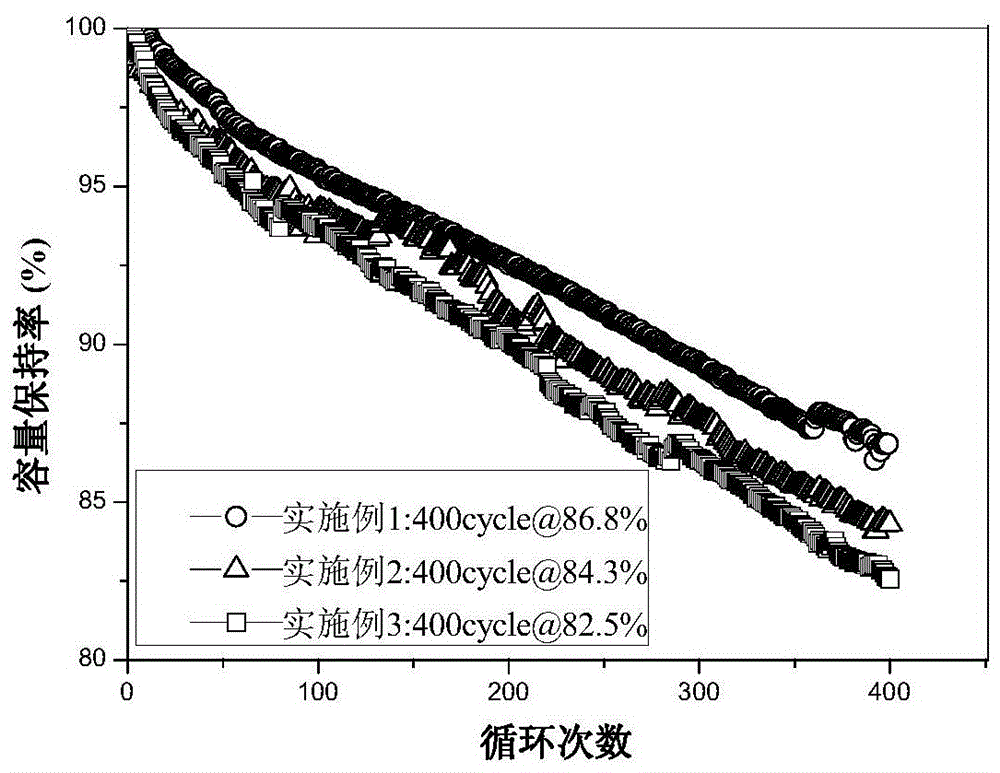

Embodiment 1

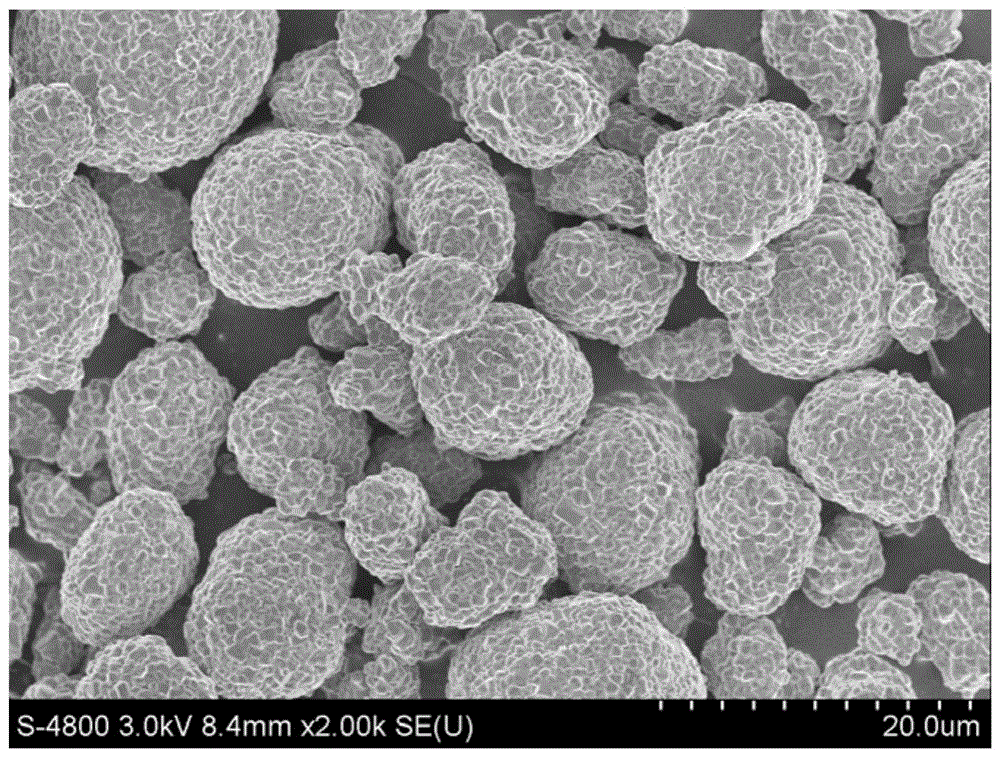

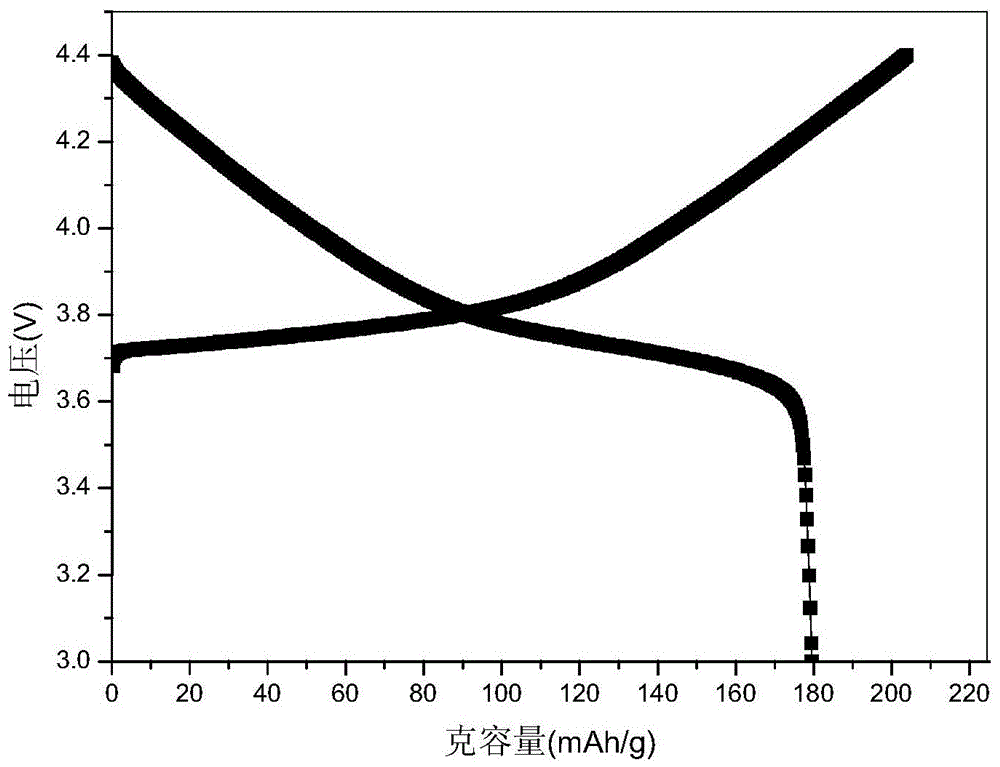

[0034] 2kg of ternary material precursor powder (manufacturer: Ningbo Jinhe New Materials Co., Ltd.), 0.870kg of lithium carbonate powder, and 1.752g of titanium dioxide powder were uniformly mixed with a high-speed mixer, and the speed of the high-speed mixer was 800rpm. Put the mixture in a bell furnace, heat up at a rate of 6°C / min in an air atmosphere, keep it at 750°C for 6 hours, then continue to heat up to 930°C for 6 hours, then cool down to room temperature with the furnace, after crushing and sieving Obtain primary powder of high-voltage nickel-cobalt-manganese-lithium oxide material;

[0035]Configure 5L of a mixed solution of magnesium nitrate and aluminum nitrate, wherein the concentration of magnesium nitrate is 0.02mol / L, and the concentration of aluminum nitrate is 0.01mol / L; add 0.5mol edetate disodium and 1mol urea to the solution, and stir at a constant speed 1h; add a small amount of ammonia water to the solution until the pH of the solution system is betwe...

Embodiment 2

[0041] 2 kg of ternary material precursor powder (same as above), 0.830 kg of lithium carbonate powder, and 2.358 g of titanium dioxide powder were uniformly mixed with a high-speed mixer, and the speed of the high-speed mixer was 900 rpm. Put the mixture in a bell-type furnace, heat up at a rate of 6°C / min in an air atmosphere, keep it at 780°C for 4 hours, then continue to heat up to 960°C for 6 hours, then cool down to room temperature with the furnace, after crushing and sieving Obtain primary powder of high-voltage nickel-cobalt-manganese-lithium oxide material;

[0042] Prepare 8L of aluminum nitrate solution, the concentration of aluminum nitrate is 0.01mol / L; add 0.4mol / L disodium edetate and 8mol / L urea to the solution, stir at a constant speed for 0.5h; add a small amount of ammonia water to the solution until the solution system pH between 6.5 and 7.0;

[0043] Add 2 kg of nickel oxide cobalt manganese lithium primary material to be coated into the prepared solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com