A kind of vibration sensitive optical fiber and its manufacturing method

A manufacturing method and optical fiber prefabricated rod technology, applied in clad optical fiber, manufacturing tools, glass manufacturing equipment, etc., can solve the problems of unfavorable optical fiber vibration sensitivity, failure to meet the use requirements, etc., and achieve resistance to external force damage and high vibration sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

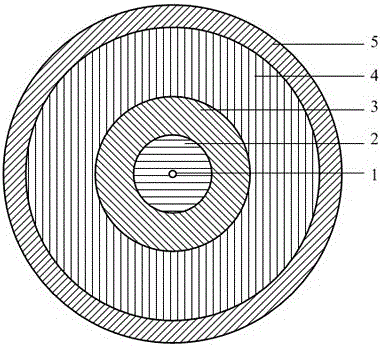

Image

Examples

Embodiment 1

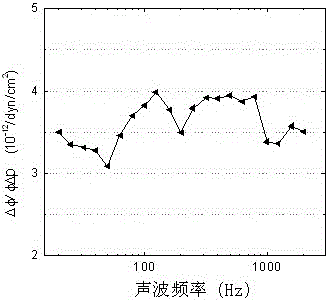

[0067] The vibration sensitivity test result of embodiment 1 is as figure 2 As shown, the vibration sensitivity value of the optical fiber produced in Example 1 is 3.5×10 -12 dyn / cm 2 .

[0068] (2) The main parameters of the vibration-sensitive optical fiber of embodiment 2 are as follows:

[0069] Fiber main parameter name

parameter value

8μm

Cladding diameter

125μm

Medium Modulus Coating Material

Feikai KG500

Medium Modulus Coating Outside Diameter

300μm

Vibration Sensitization Layer Material

PVC HP17653

Vibration-sensitizing layer outer diameter

600μm

Outer sheath material

Polyurethane (TPU)

Outer sheath outer diameter

1000μm

[0070] The manufacturing method of the brake-sensitive optical fiber is as follows:

[0071] Step 1: Using the MCVD process, the quartz glass deposition tube is placed on the lathe for high-temperature flame polishing thr...

Embodiment 2

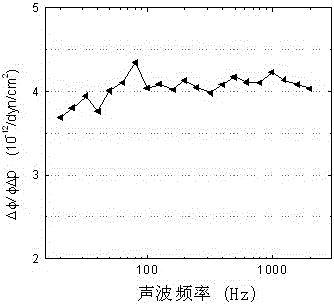

[0086] The vibration sensitivity test result of embodiment 2 is as image 3 As shown, the vibration sensitivity value of the optical fiber produced in Example 2 is 4.1×10 -12 dyn / cm 2 .

[0087] (3) The main parameters of the vibration-sensitive optical fiber of embodiment 3 are as follows:

[0088] Fiber main parameter name

parameter value

8μm

Cladding diameter

125μm

Medium Modulus Coating Material

Feikai KG500

Medium Modulus Coating Outside Diameter

300μm

Vibration Sensitization Layer Material

ETFE 750

Vibration-sensitizing layer outer diameter

700μm

Outer sheath material

Polyolefin (Kaibo 5505)

Outer sheath outer diameter

1000μm

[0089] The vibration-sensitive optical fiber is fabricated as follows:

[0090] Step 1: Using the MCVD process, the quartz glass deposition tube is placed on the lathe for high-temperature flame polishing through a flame...

Embodiment 3

[0106] The vibration sensitivity test result of embodiment 3 is as Figure 4 As shown, the vibration sensitivity value of the optical fiber produced in Example 3 is 4.6×10 -12 dyn / cm 2 .

[0107] The optical fiber preform mentioned above can also be manufactured by other methods, or purchased directly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com