Method and device for testing dynamic shear fracture toughness of brittle materials

A shear fracture, brittle material technology, applied in the direction of using a stable shear force to test the material strength, etc., can solve the problems of crack initiation, unavoidable tensile stress components, and no pure shear fracture. The effect of accurate testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

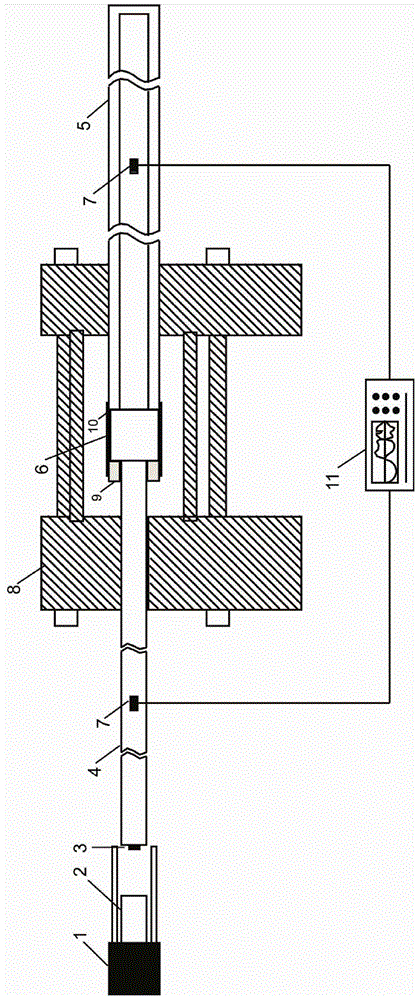

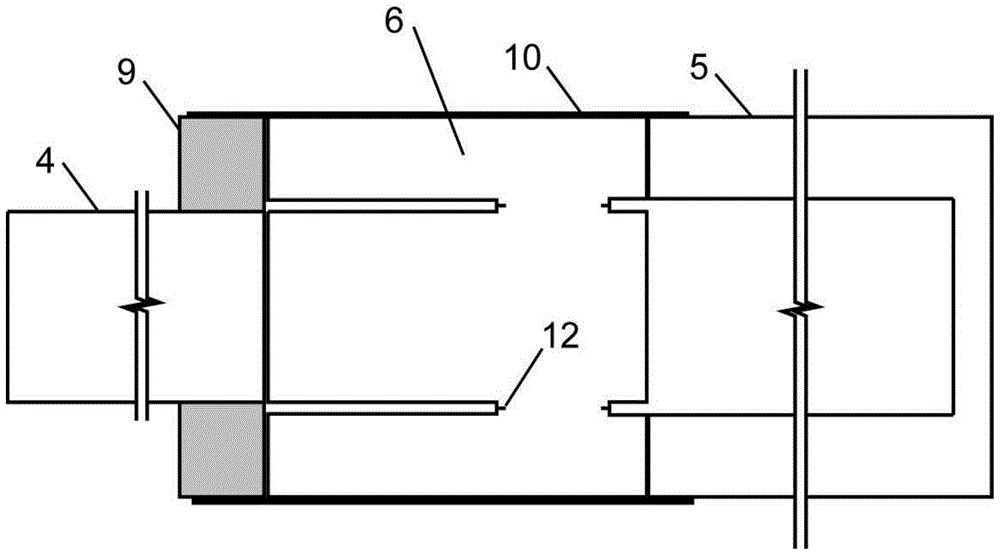

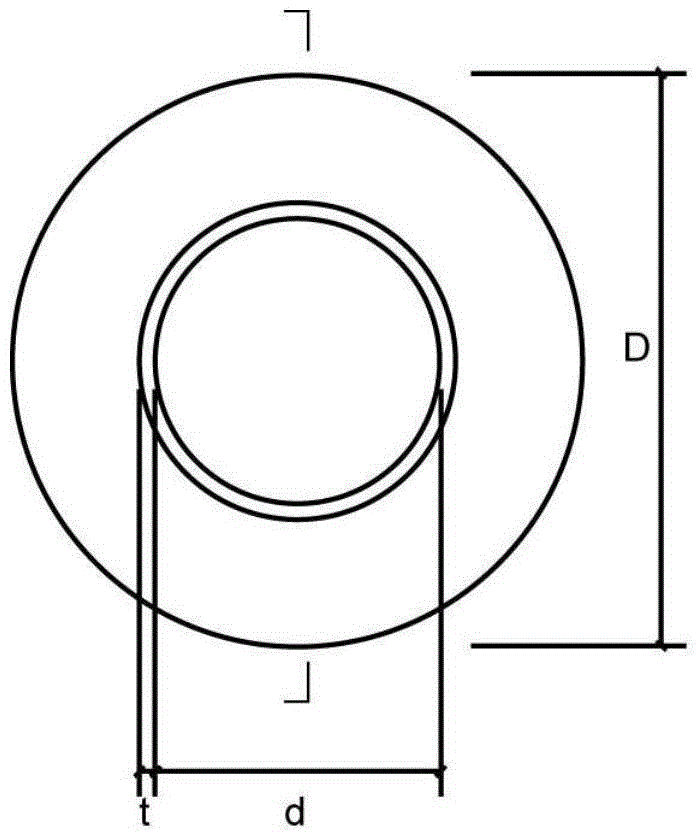

[0028] The indoor dynamic shear fracture toughness testing experimental device of this embodiment has a structure as attached figure 1As shown, its composition mainly includes the impact bomb launching device 1, the incident rod 4, the corrugated shaping sheet 3 arranged at the front end of the incident rod, the transmission rod 5, the strain gauge 7 attached to the incident rod and the transmission rod, and the holding cylinder Type sample installation device, confining pressure chamber 8, and data acquisition and processing system 11, the rear end of the incident rod is located in the confining pressure chamber, the front end of the incident rod passes through the front end of the confining pressure chamber and corresponds to the launch bore of the impact bomb launcher, and the transmission rod The front end passes through the back end of the confining pressure chamber and extends into the confining pressure chamber and is set opposite to the rear end of the incident rod to f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com