A Method for Predicting the Service Life of Vacuum Insulation Panels (zkb)

A technology of a vacuum insulation panel and a prediction method, which is used in the testing of machine/structural components, vacuum gauges with a compression chamber for compressing the gas to be measured, measuring devices, etc. Vacuum degree is not easy to measure and other problems, to ensure the effect of thermal insulation effect and small economic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

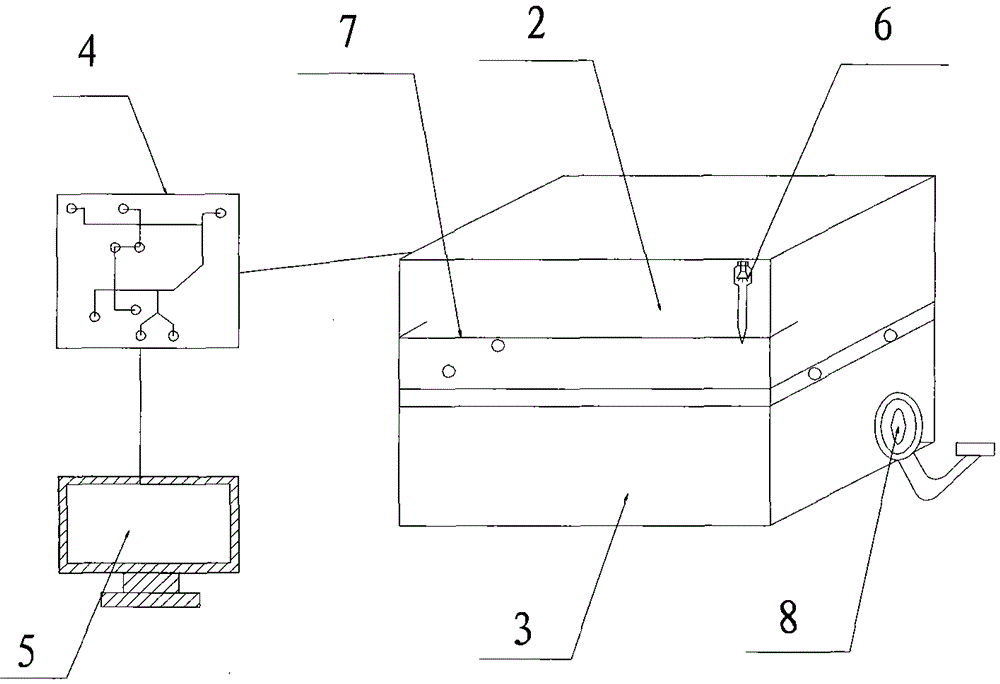

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0024] The present invention provides a method for predicting the service life of a vacuum insulation panel (ZKB) for evaluating the durability of a vacuum insulation panel.

[0025] A method for predicting the service life of a vacuum insulation panel (ZKB), comprising the following steps:

[0026] (1) Measure the initial vacuum degree p of the vacuum insulation panel (ZKB) 初始 , the unsealed high-barrier film bag after loading the core material such as figure 2 As shown, 1 is the core material, and 2 is the high barrier film bag;

[0027] (2) Test the air pressure difference Δp on both sides of the high barrier membrane 检测 ;

[0028] (3) Test the gas permeation φ of the high barrier film per unit area and per unit time 检测 ;

[0029] (4) Test the volume v of the vacuum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com