Rat-proof PVC (polyvinyl chloride) material

A rodent-proof and rodent-repelling technology, which is applied in the field of rodent-proof PVC plastic materials for wires and cables, can solve the problem of not mentioning the content of n-nonanoic acid vanillyl amide, not specifying the purity of capsaicin, not mentioning natural biological purification or Chemical synthesis of capsaicin and other issues to achieve reasonable production costs and control production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

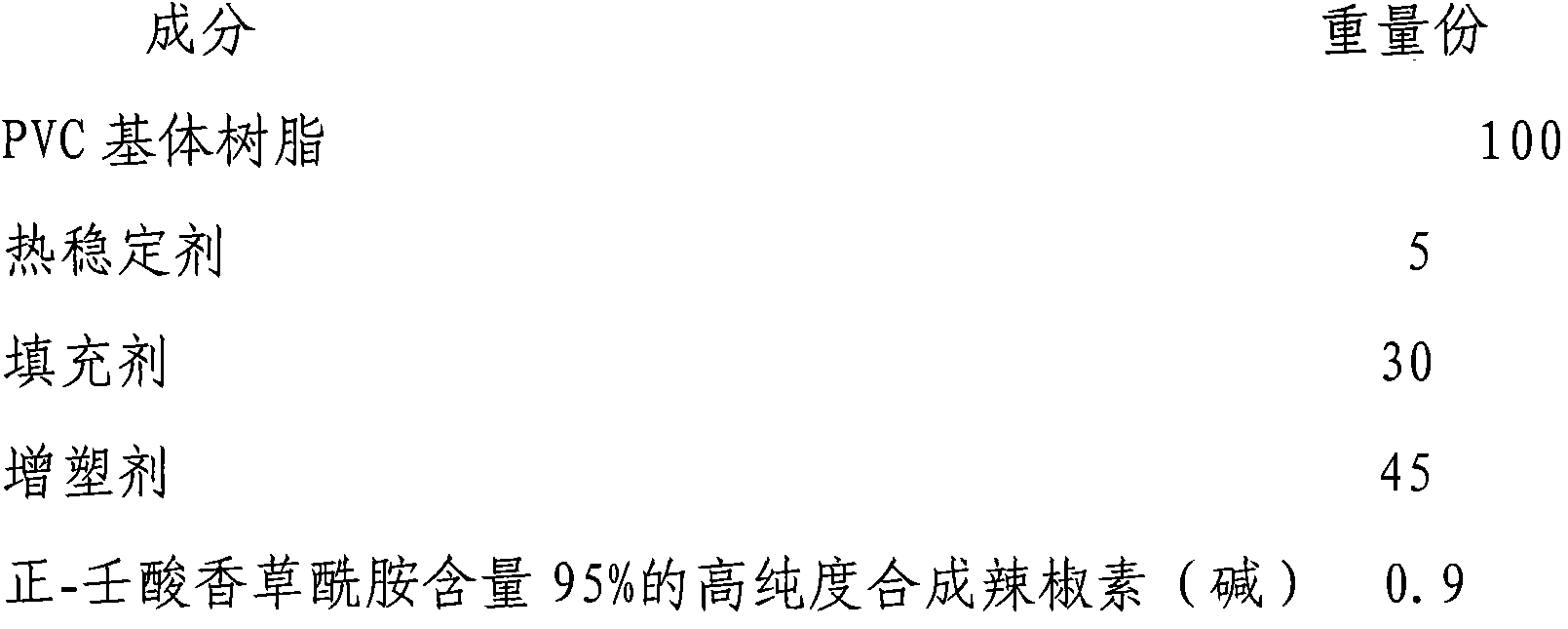

[0021] The components of this embodiment are as follows:

[0022]

[0023] The preparation method of above-mentioned anti-rat PVC material is as follows:

[0024] (1) First, the high-purity capsaicin (alkali) with a content of 95% nonanoic acid vanillic amide is pulverized into powder or granular form by a pulverizer, or the synthetic capsaicin (alkali) is heated to 40°C-100°C slowly Slowly melts into a liquid state;

[0025] (2) Stir the high-purity synthetic capsaicin (alkali) and plasticizer of n-nonanoic acid vanillylamide content 95% after crushing or melting in a high-speed mixer;

[0026] (3) The plasticizer and the PVC matrix resin, heat stabilizer, filler are blended again with the high-purity synthetic capsaicin (alkali) of n-nonanoic acid vanillic acid amide content 95% homogeneously, and mix homogeneously;

[0027] (4) Finally, send the blended anti-rat PVC raw material into the extruder to obtain the anti-rat PVC material.

Embodiment 2

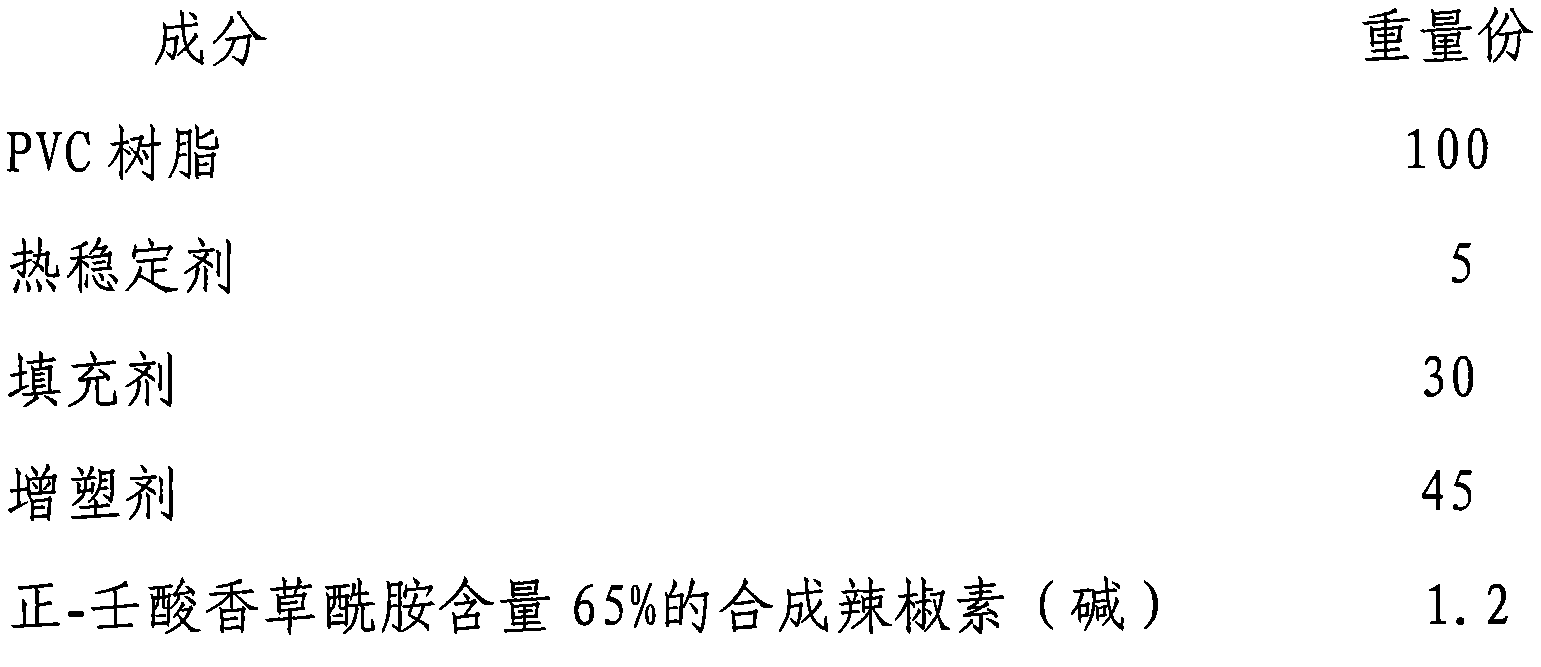

[0029] The components of this embodiment are as follows:

[0030]

[0031] The preparation method of above-mentioned anti-rat PVC material is the same as embodiment 1

Embodiment 3

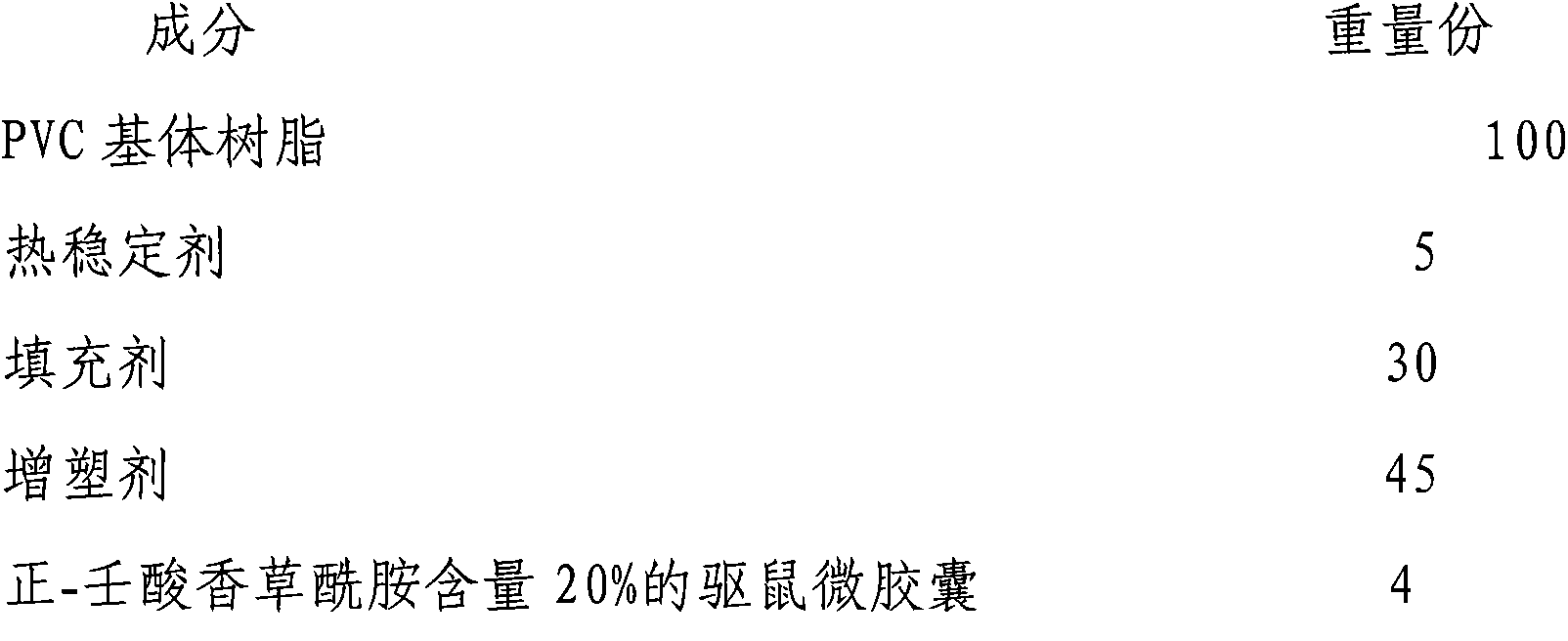

[0033] The components of this embodiment are as follows:

[0034]

[0035] The preparation method of above-mentioned anti-rat PVC material is as follows:

[0036] (1) earlier, the mouse-repelling microcapsules with 20% content of nonanoic acid vanillylamide and the PVC matrix resin are blended evenly;

[0037] (2) Continue to blend evenly with plasticizer, thermal stabilizer, filler, and the PVC matrix resin mixed homogeneously with the rodent-repelling microcapsules;

[0038] (3) Finally, send the mixed anti-rat PVC raw material into the extrusion machine to obtain the anti-rat PVC material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com