Dual-compression die

A technology of pressing molds and templates, which is applied to forming tools, manufacturing tools, metal processing equipment, etc., can solve the problem of inconvenient opening of molds, and achieve the effect of reasonable control of production costs and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below through specific examples, but not in order to limit the present invention, all within the spirit and principle of the present invention, any modification, equivalent replacement, improvement etc. all should be included within the scope of protection of the present invention .

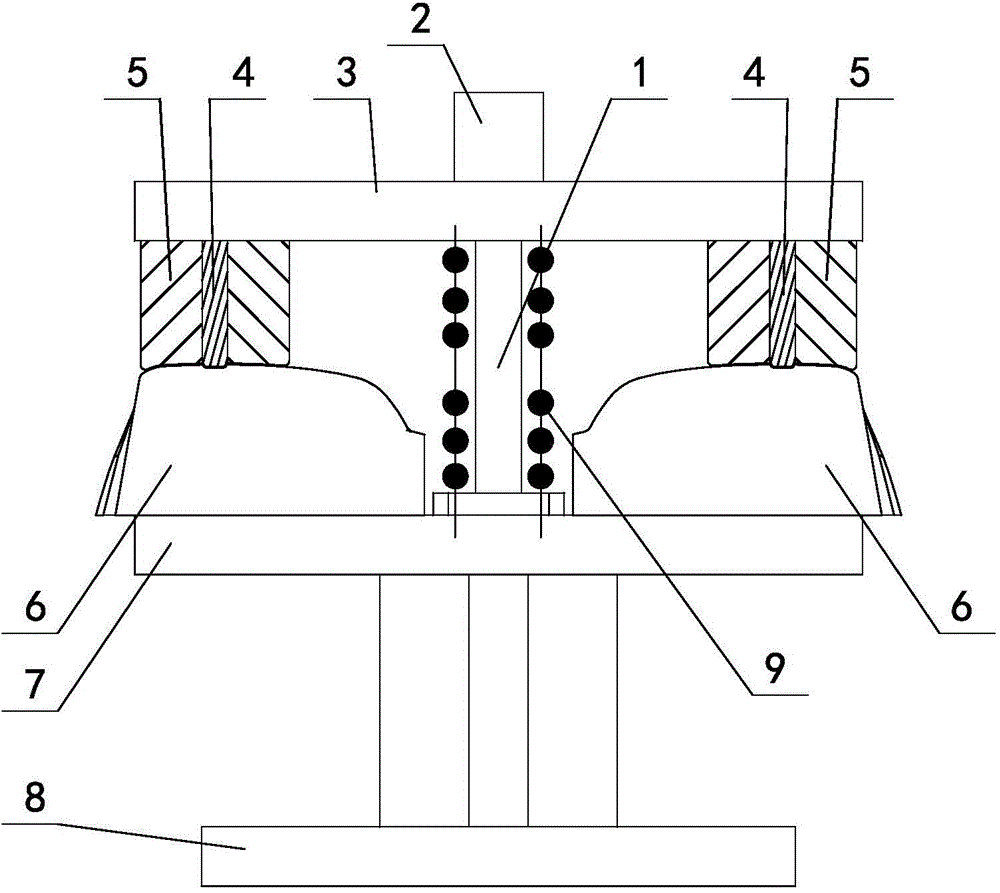

[0014] Such as figure 1 As shown, the double-press mold includes an upper mold and a lower mold that cooperate with each other. The upper mold includes an upper mold 3, and the left and right ends of the bottom of the upper mold 3 are respectively provided with a pressure punch 4. The lower mold includes a bracket 8, corresponding to the upper mold 3. A lower formwork 7 is provided on the top of the support 8, and the corresponding pressing punch 4 is respectively provided with a cavity mold 6 at the left and right ends of the top of the lower formwork 7, and a guide column 1 for the upper formwork 3 to move up and down is provided in the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com