A kind of biological organic fertilizer and its production method

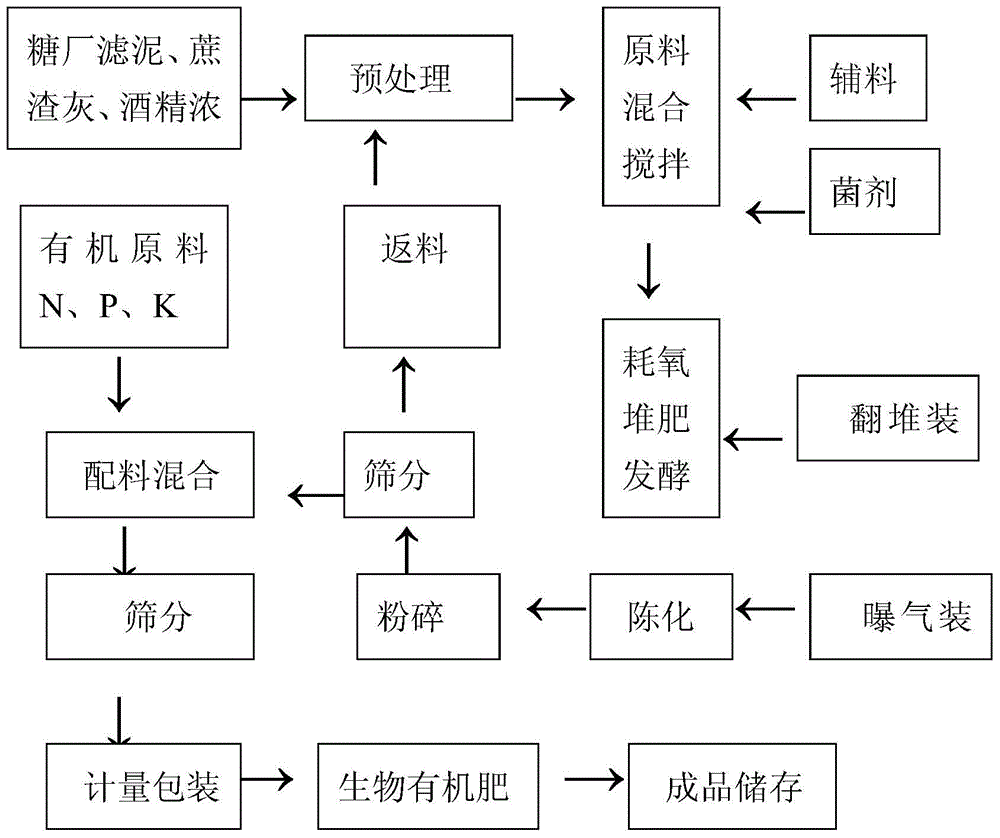

A bio-organic fertilizer and material technology, which is applied to the treatment of bio-organic parts, organic fertilizers, and the preparation of organic fertilizers, can solve the problems of ineffective bio-organic fertilizers and immature fermentation, and achieve easy screening and reuse, Accelerates the loss of water and promotes the effect of microbial growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Bacteria preparation: weigh 10% bifidobacteria, 11% lactic acid bacteria, 11% bacillus, 50% yeast, 13% actinomycetes, and 5% acetic acid bacteria by volume. According to the sugar factory waste, 10% of sugar factory filter mud, 75% of bagasse ash, 15% of alcohol concentrate, the amount of fermentation bacteria is 3% of the total amount of raw materials in the stack-type mixture fermentation pile, and they are stacked together. Filter the stacked raw materials, filter out the water, mix the materials to be fermented with the amount of bacteria that is 3% of the total weight of the mixture, and then press the bottom width of the pile to be 200cm, the pile length to be 250cm, and the pile height to be 100cm. Stack and start fermentation. Keep the temperature of the fermentation heap 5 to 6 days before fermentation up to above 60°C, and control the moisture content of the heap material at about 45%. The turning machine turns over the fermentation pile once or twice a day. ...

Embodiment 2

[0028] Bacteria preparation: weigh 15% bifidobacteria, 7% lactic acid bacteria, 16% bacillus, 40% saccharomyces, 21% actinomycetes, and 1% acetic acid bacteria by volume. According to the sugar factory waste, 20% of sugar factory filter mud, 55% of bagasse ash, 25% of alcohol concentrate, the amount of fermentation bacteria is 4% of the total amount of raw materials in the stack-type mixture fermentation heap, and they are stacked together. After placing for 1 day, put The piled raw material is filtered, mainly to filter out moisture, and the filtered material is mixed with the amount of bacteria that is 4% of the total weight of the mixture, and the material that is about to be fermented is mixed, and then the bottom width of the pile is 200 cm, and the length of the pile is 200 cm. 300cm, 100cm high strip stack stacking, start fermentation. Keep the temperature of the fermentation heap 5 to 6 days before fermentation up to above 60°C, and control the moisture content of the ...

Embodiment 3

[0030]Bacteria preparation: weigh 13% of bifidobacteria, 9% of lactic acid bacteria, 10% of bacillus, 45% of saccharomyces, 17% of actinomycetes, and 6% of acetic acid bacteria by volume. According to the sugar factory waste, 16% of sugar factory filter mud, 64% of bagasse ash, 20% of alcohol concentrate, the amount of fermentation bacteria is 5% of the total amount of raw materials in the stacked mixture fermentation pile, and they are stacked together. After placing for 1 day, put The piled raw material is filtered, mainly to filter out moisture, and the filtered material is mixed with the amount of bacteria that is 5% of the total weight of the mixture, and the material that is about to be fermented is mixed, and then the bottom width of the pile is 200cm, and the pile length is 200cm. 200cm, piled up 100cm in strips and stacked, and started to ferment. Keep the temperature of the fermentation heap 5-6 days before fermentation up to above 60°C, and control the moisture cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com