Automatic station welding gun electrode stem for robot

An electrode rod and robot technology, applied in the field of electrode rods, can solve the problems of easy deformation of the electrode rod, false welding, affecting the concentricity, etc., and achieve the effects of not easily deforming the concentricity, low price, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

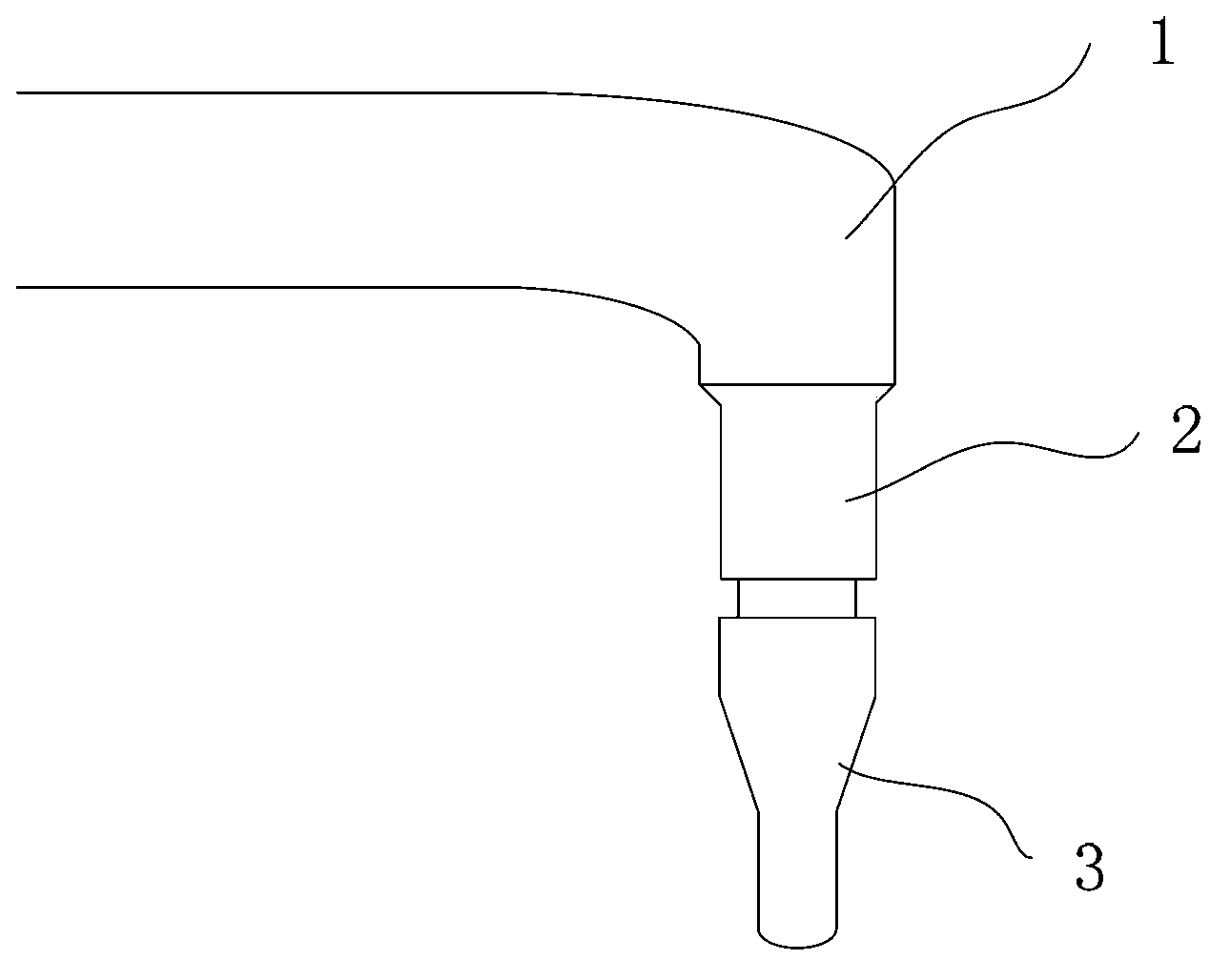

[0019] Such as figure 1 As shown, an electrode rod for a robot automatic station welding torch includes a rod body 1 of the electrode rod and a base 2 arranged at the front end of the rod body 1 , and an electrode cap 3 is sheathed on the base 2 . The rod body 1 and the base 2 are integrally formed by casting, which is not easy to be deformed and affect the concentricity. The overall length of rod body 1 and base 2 is increased by 10mm compared to the original length, while electrode cap 3 is shortened by the same length, so that the length of the entire electrode rod is consistent with the original length, which can effectively solve the problem of circulating water cooling caused by too long electrode cap Not good, easy to produce problems such as false welding, so as to improve the processing quality and efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com