A kind of hollow fiber membrane plug processing technology

A processing technology and fiber membrane technology, applied in the field of hollow fiber membrane plug processing technology, can solve the problems of high production cost, unguaranteed plugging effect, complex processing technology of hollow fiber membrane plug, etc., and achieve low cost, The effective filtration area is maximized and the plugging height is basically the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

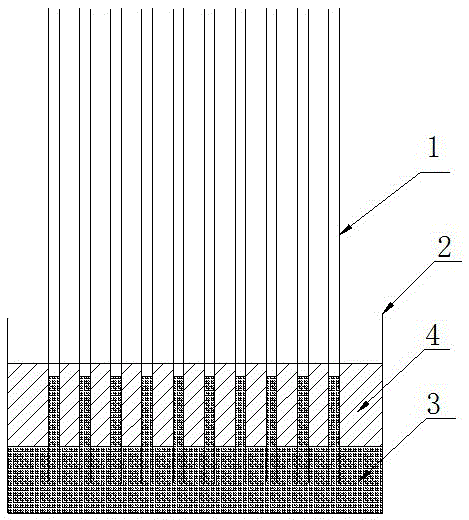

[0024] A hollow fiber membrane plug processing technology, as shown in Figure 1, 5 bundles, each bundle of 220 hollow fiber membrane filaments 1 with a length of 1.0m, an outer diameter of 1.1mm, and an inner diameter of 0.55mm to form an ultrafiltration membrane bundle, and the upper end is used as a conventional package end. Cut the lower ends of the membrane filaments 1 and spread them out naturally to form a free end. Lift the packaging end of the ultrafiltration membrane bundle and insert the free end vertically into the open container 2, 1 cm away from the bottom of the open container 2; pour glue into the open container 2 Layer 3 liquid epoxy resin is 10cm high, so that the outer and inner holes of the lower end of the hollow fiber membrane filament 1 are filled with epoxy resin; then slowly pour into the pressure layer 4 n-octane, pouring height 0.1cm, keep constant n-octane It is on the upper layer of epoxy resin and does not penetrate each other. The epoxy resin glue...

Embodiment 2

[0026] A hollow fiber membrane plug processing schematic diagram is the same as that of Example 1, except that the glue layer 3 liquid is polyurethane, and the polyurethane is poured into the open container 2 with a height of 0.5 cm, so that the outer side of the lower end of the hollow fiber membrane filament 1 and the The inner hole is filled with polyurethane; then slowly pour 4 liquid anhydrous ethanol into the pressure layer, and the pouring height is 10cm. After keeping constant, the anhydrous ethanol is on the upper layer of polyurethane and does not penetrate each other. The glue on the outside moves down, the glue in the inner hole of the membrane filament rises, seal the open container 2, and wait for the polyurethane glue to solidify; let it stand at room temperature (25°C) for 4 hours, and pour out the liquid in the pressure layer 4 after the polyurethane in the glue layer 3 solidifies Absolute ethanol is collected and recycled; at this time, it is found that the ou...

Embodiment 3

[0028] A hollow fiber membrane plug processing process, the schematic diagram is similar to that of Example 1, a bundle of 3000 hollow fiber membrane filaments 1 with a length of 1.0 m, an outer diameter of 1.3 mm, and an inner diameter of 0.70 mm is formed into an ultrafiltration membrane bundle, The upper end is used as the conventional package end. Put it into a plastic shell with a diameter of 10cm, and use glue to let it stand for packaging and cut out the film hole.

[0029] Tidy up the lower end, tie it tightly with a rope, and cut it at a distance of 1 cm from the bottom to form a free end, and the membrane filaments 1 are scattered. Fix the packaging end of the component and lift it, insert the free end vertically into the open container 2, 0.05cm away from the bottom of the open container 2, pour the glue layer 3 epoxy resin liquid 3cm deep into the open container 2 with a diameter of 15cm, and make the hollow fiber membrane The outer side and the inner hole of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com