Automatic food production and processing equipment and production and processing method

A technology of automatic production and processing equipment, applied in the field of food processing and production, can solve the problems of high labor consumption, limited processing speed, sticking of knives, etc., so as to avoid the reduction of taste lubricity, improve food taste quality, and reduce cooling requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

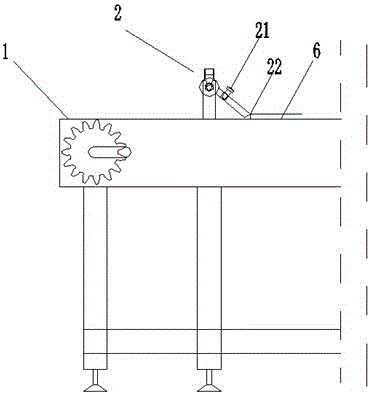

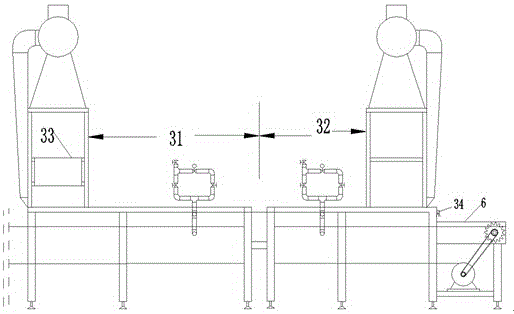

[0029] Example: Figure 1 to Figure 6 In order to utilize the overall schematic diagram and partial schematic diagram of the production line of the fish tofu produced by the present invention, it can be clearly seen from the figure that the equipment of the present invention comprises: the first conveyor belt 1, the feeding port 2, the shaping tank 6, the segmental heating system, the second conveyor belt 4 and an automatic cutting system, wherein the sizing groove 6 is fixed on the first conveyor belt 1 and circles the first conveyor belt 1 end-to-end, and the feeding port 2 is connected to the sizing groove 6, so The sectional heating system is divided into a first heating zone 31 and a second heating zone 32, the first conveyor belt 1 passes through the first heating zone 31 and the second heating zone 32 in sequence and then docks with the second conveyor belt 4 , the automatic cutting system is erected above the second conveyor belt, and the food on the second conveyor be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com