Evaporator burner for a mobile heating device

A technology of heating device and vaporizer, which is applied in the field of vaporization burner, can solve the problems of deteriorating combustion characteristics, and achieve the effects of good combustion characteristics, strong cooling and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

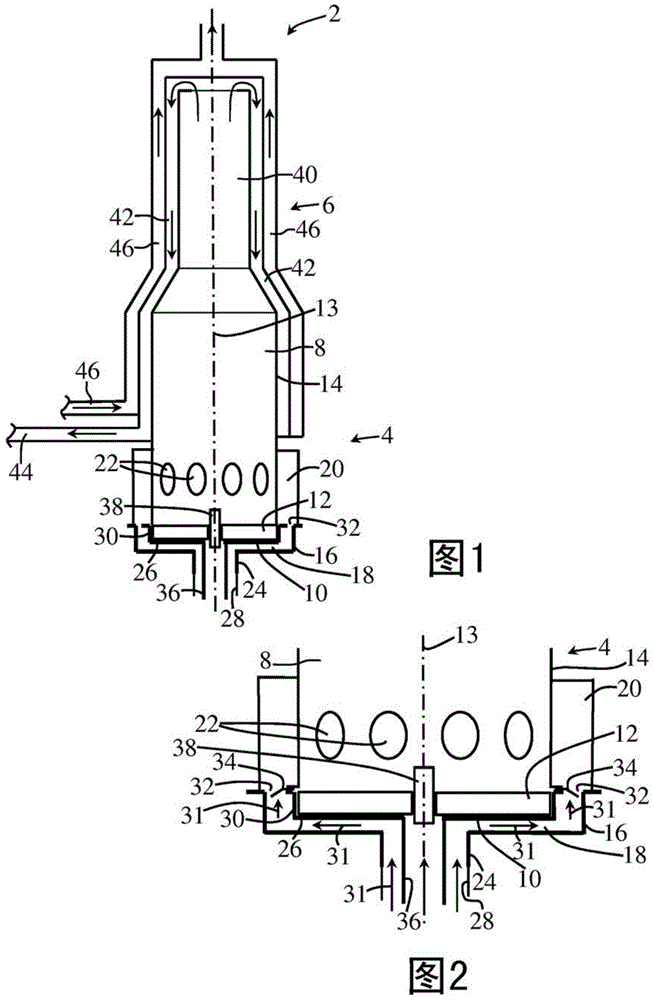

[0030] exist figure 1 In , a mobile fuel-operated heating device 2 forming a parking heater for a land vehicle is schematically shown. In the following, reference is made in particular to those parts which have a certain relation to the present invention. The heating device 2 includes a vaporization burner 4 and a heat exchanger 6 . Among other components, the vaporization burner 4 comprises a combustion chamber 8 , a vaporizer receptacle 10 and a vaporizer element 12 for vaporization of liquid fuel. The combustion chamber 8 , the evaporator receptacle 10 and the evaporator element 12 are substantially circular and comprise a common axis of rotational symmetry 13 .

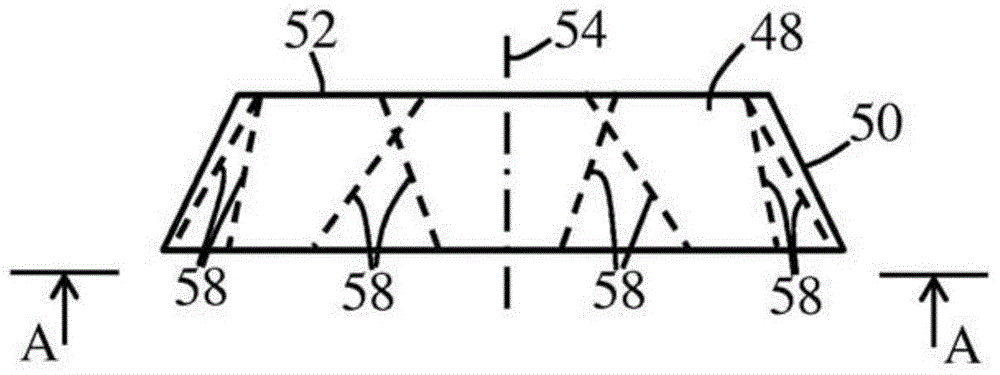

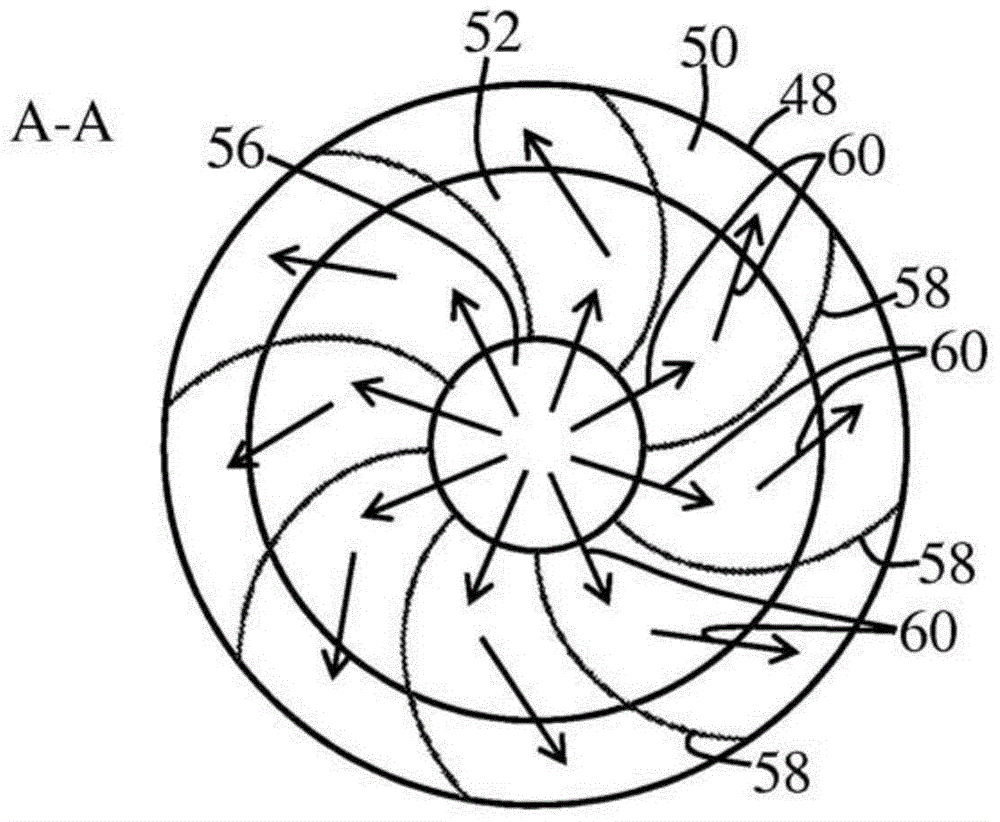

[0031] In the circumferential direction, the combustion chamber 8 is delimited by a circumferential combustion chamber wall 14 . On the front side of the fuel supply area, the combustion chamber 8 is delimited by a carburetor receptacle 10 . The evaporator element 12 is accommodated in the side of the evaporat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com