Nozzle systems for edgebanding plants impinging hot air on adhesive-free, heat-activatable or provided edgebands or workpieces with hot-melt adhesive and edgebanding systems with nozzle systems

An adhesive-free, edge-banding technology, used in other plywood/plywood appliances, manufacturing tools, wood processing appliances, etc., can solve the problems of technical difficulties in the process, damage to the visual image, unsatisfactory operation speed, etc. High exothermic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

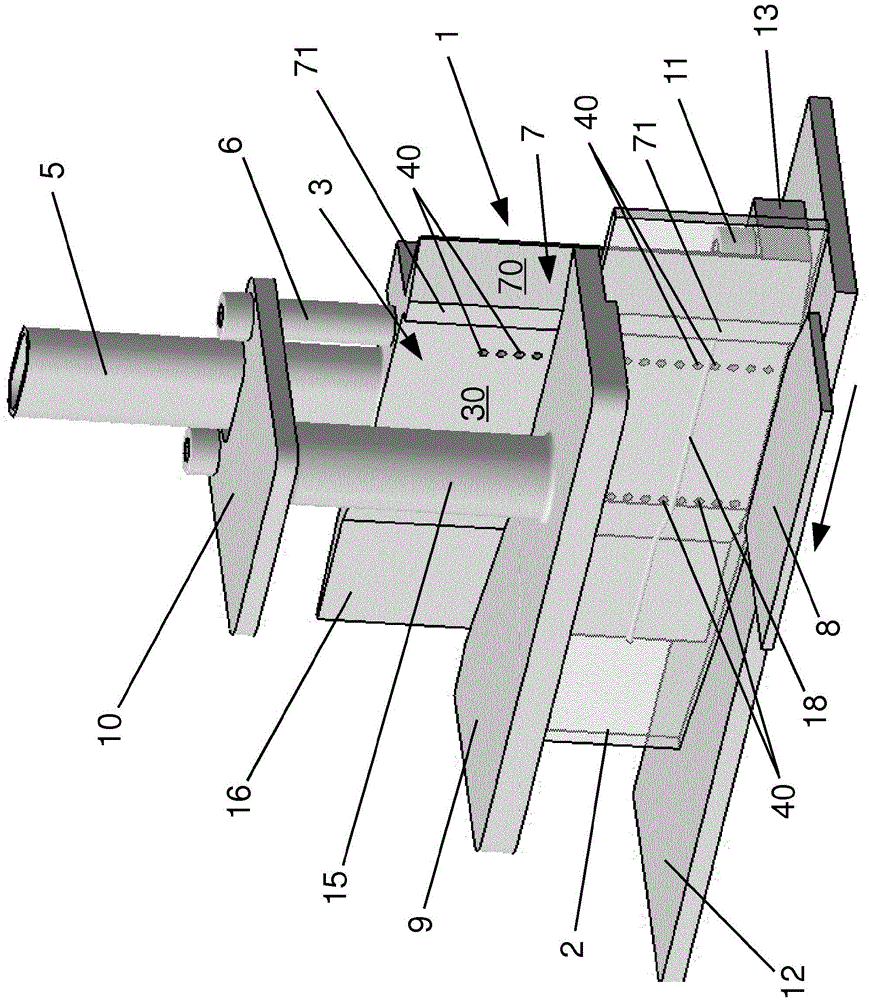

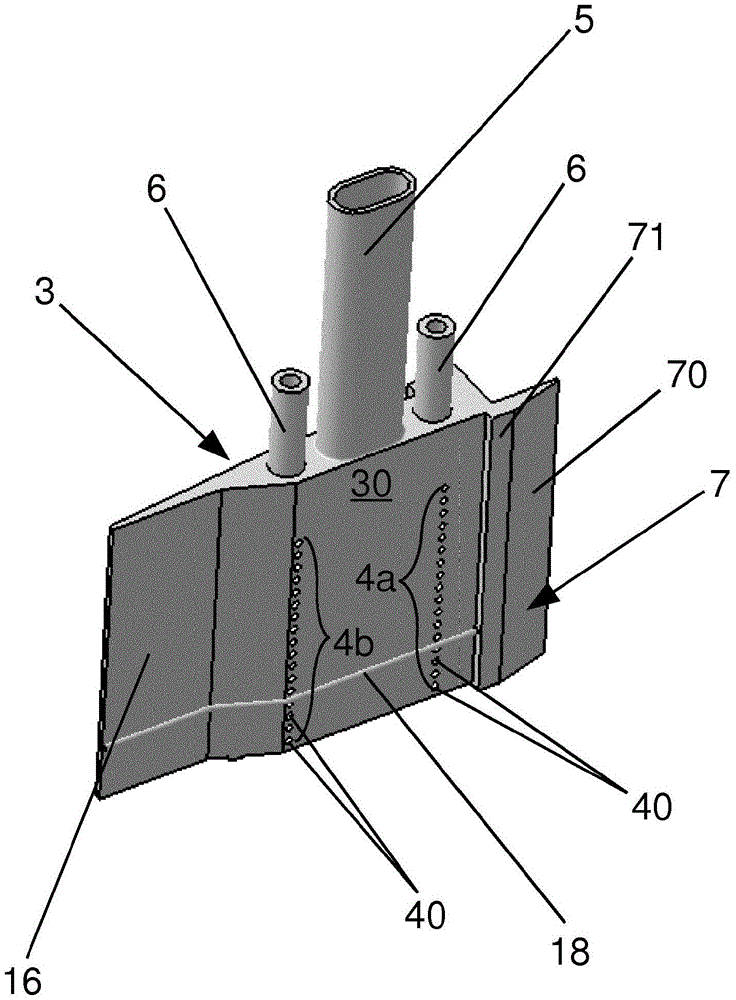

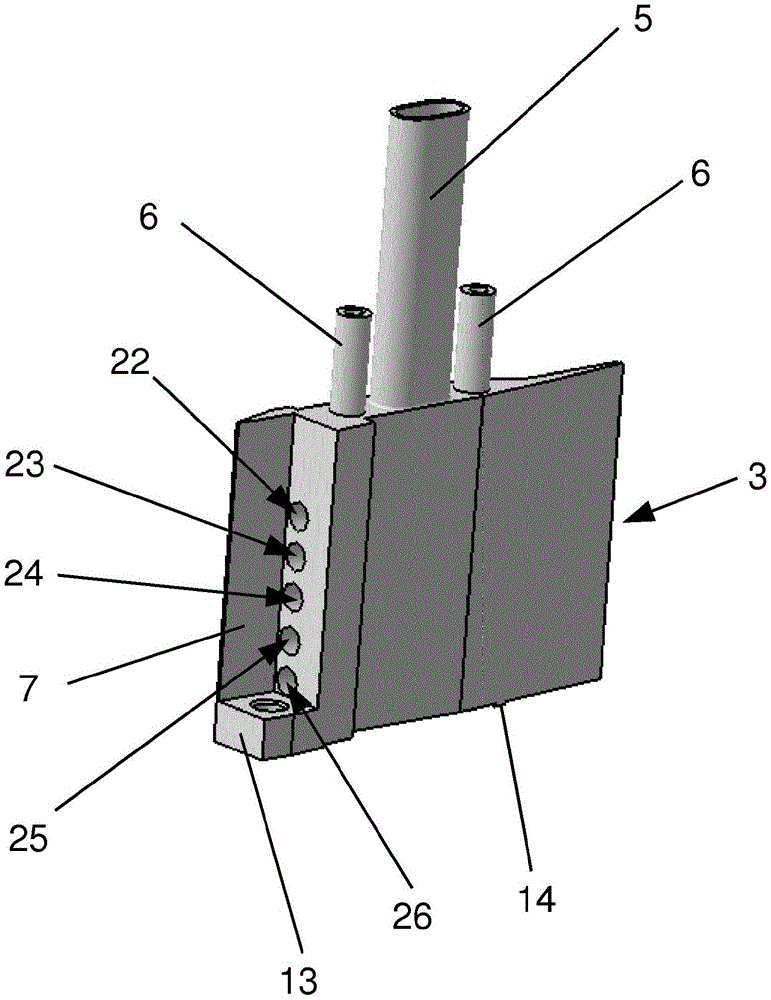

[0031] The following should refer to figure 1 The basic design and structure of the nozzle system 1 according to a preferred embodiment of the present invention is further explained. The nozzle system is used for the adhesive-free, heat-activatable edge banding 2 to impact hot air edge banding. equipment. The nozzle system 1 includes a nozzle body 3, which in this embodiment is made of heat-resistant steel in one piece. The nozzle body 3 is shaped so that it is transverse to the figure 1 The feeding direction of the edge band 2 indicated by the arrow in is configured to be relatively narrow, because the space available for the positioning of the nozzle system 1 in the edge band application equipment is usually relatively narrow. The nozzle system 1 is arranged in the edge band processing equipment in such a way that the nozzle system is positioned directly in front of the first edge band pressing roller along the feed direction of the edge band 2, and the edge band 2 uses the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com