Flexible Electric Cutter for High Voltage Cable Outer Sheath

A technology for high-voltage cables and outer sheaths, which is applied to equipment for connecting/terminating cables, etc. It can solve problems such as uneven cutting and production, high working intensity, broken knives, and hand injuries, so as to achieve good cutting quality and ensure Construction quality, simple construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

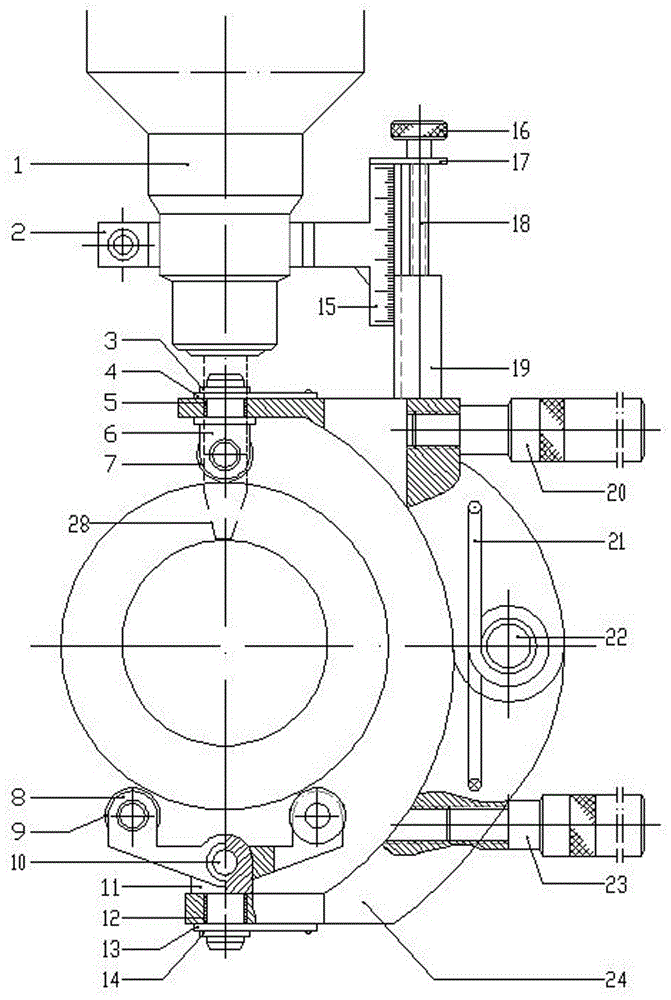

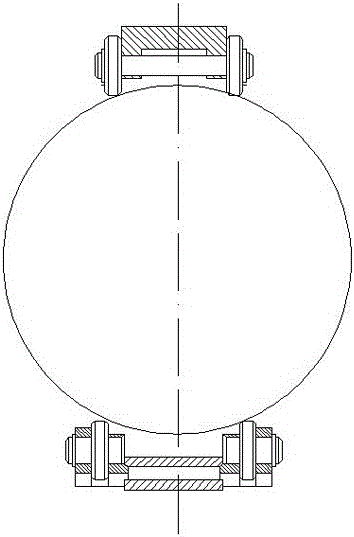

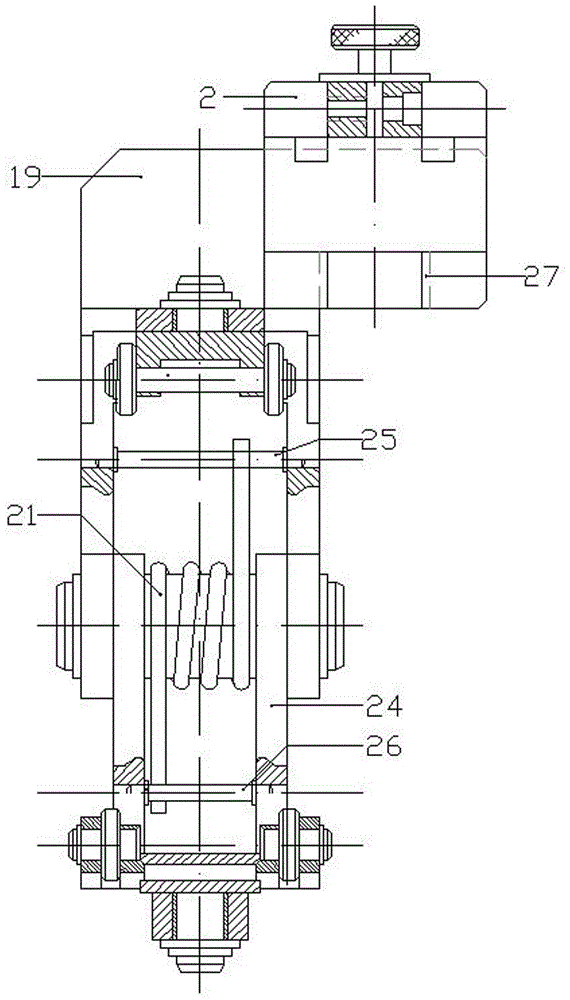

[0015] Such as figure 1 and figure 2 As shown, the high-voltage cable outer sheath flexible electric cutter includes a power head 1, a power head bracket 2 is installed on the power head 1, a cutter 28 and an adjustment device for adjusting the position of the cutter are installed on the power head bracket 2, and the precise To control the feed size, the adjustment device is fixed on the upper cutter body 19, the upper cutter body 19 and the lower cutter body 24 are fixed by the mandrel 22 and the spring 21 wound on the mandrel 22, and the upper cutter body corresponding to the cutter 28 19 is provided with an adjustable upper guide wheel 7, and the lower cutter body 24 corresponding to the upper guide wheel 7 is provided with an adjustable lower guide wheel 9.

[0016] Adjusting device comprises feed scale 15, and the upper end of feed scale 15 is arranged on feed screw rod 18 by feed connecting plate 17, and the middle part of feed scale 15 connects power head support 2; T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com