Device used for replacing spacers on ultra-high voltage transmission line

A technology of transmission lines and spacers, which is applied in the direction of overhead lines/cable equipment, etc., can solve the problems of inconvenient operation, slow replacement speed, inconvenient carrying, etc., and achieve the effect of convenient operation, labor-saving, simple structure, and versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

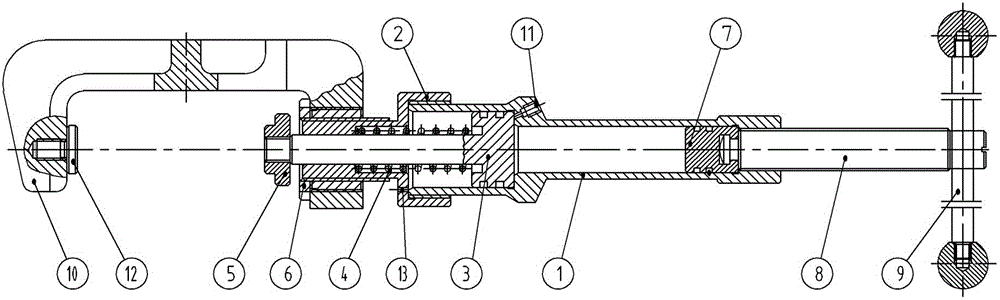

[0015] Such as figure 1 As shown, the universal tool for replacing spacer rods on UHV transmission lines disclosed by the present invention includes adjusting oil cylinder 1, oil cylinder liner 2, piston rod 3, compression spring 4, upper positioning block 5, adjusting screw sleeve 6, Piston 7, adjusting screw mandrel 8, adjusting handle 9 and C-shaped chuck 10.

[0016] The cylinder body of regulating oil cylinder 1 is the double-chamber cylinder body that the front is large and the rear is small, and its front chamber is a decompression chamber, and its outer wall head has external threads. The longitudinal section shape of the oil cylinder liner 2 is T-shaped, with a T-shaped through hole in the axial center, an internal thread on the head hole wall, and an exhaust hole 13 at the bottom. The oil cylinder liner 2 is connected to the outer wall of the pressure reducing chamber of the regulating oil cylinder 1 through threads. Stage clip 4 is connected to the outer wall of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com