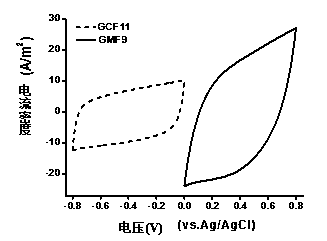

Preparation method for flexible graphite fibre-based asymmetric super capacitor

A supercapacitor and graphene fiber technology, which is applied in the manufacture of hybrid/electric double layer capacitors, can solve the problems of one-dimensional graphene fiber-based flexible asymmetric supercapacitors, and achieve good flexibility and bending stability. High specific capacitance, the effect of expanding the working voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The steps of the preparation method of the flexible graphene fiber-based asymmetric supercapacitor are as follows:

[0033] 1) Dissolving the graphene oxide raw material in a solvent to obtain a graphene oxide spinning slurry with a mass percentage of 0.1%-3%;

[0034] The solvent can be any one of deionized water, N-methyl-2-pyrrolidone, N,N-dimethylformamide, N,N-dimethylacetamide, dimethylsulfoxide, sulfolane or a variety of mixtures in any proportion.

[0035] 2) Pass the graphene oxide spinning slurry obtained in step 1 through a spinning nozzle with a diameter of 10-5000 μm at an extrusion speed of 10-2000 μL / min, stay in a coagulation solution at 5-35°C for 1-3600s, and wash, vacuum drying to obtain graphene oxide fibers;

[0036] The coagulation liquid is a water-based coagulant or an organic coagulant; the solvent of the water-based coagulant is composed of ethanol and water in a volume ratio of 1-9:3, and the solute is calcium chloride or manganese acetate. ...

Embodiment 1

[0056] 1) Dissolve the graphene oxide raw material in deionized water to obtain a mass percentage of 0.1%

[0057] 2) Pass the graphene oxide spinning slurry obtained in step 1 through a spinning nozzle with a diameter of 10 μm at an extrusion speed of 10 μL / min, and stay in the water-based coagulation solution at 35°C for 600 seconds. It is the mixed liquid of ethanol and water of 1:3, and the mass ratio of solute calcium chloride and solvent is 1:100, then washes with detergent, and detergent is made up of ethanol, 80 o C vacuum drying, obtains graphene oxide fiber;

[0058] 3) Place the graphene oxide fiber obtained in step 2 in hydrazine vapor for 90 o C reduced for 1h to obtain graphene fibers;

[0059] 4) Soak the graphene fibers obtained in step 3 in an aqueous solution of potassium permanganate with a concentration of 0.1g / L and a temperature of 5°C, react for 24 hours, take out and wash, 80 o C is vacuum-dried to obtain the graphene fiber modified by manganese diox...

Embodiment 2

[0066] 1) Dissolving the graphene oxide raw material in deionized water to obtain a graphene oxide spinning slurry with a mass percentage of 3%;

[0067] 2) Pass the graphene oxide spinning slurry obtained in step 1 through a spinning nozzle with a diameter of 5000 μm at an extrusion speed of 2000 μL / min, and stay in an organic coagulation solution at 5 °C for 300 seconds, and the organic coagulation solution is composed of acetone as a solvent , then 60 o C vacuum drying, obtains graphene oxide fiber;

[0068] 3) Place the graphene oxide fibers obtained in step 2 in 50% sodium ascorbate aqueous solution at 85°C to obtain graphene fibers;

[0069] 4) Soak the graphene fibers obtained in step 3 in an aqueous potassium permanganate solution with a concentration of 1g / L and a temperature of 70°C, react for 10 minutes, remove and wash, and dry in vacuum at 80°C to obtain manganese dioxide-modified graphene fibers ;

[0070] 5) Dissolve graphene oxide and carboxylated multi-wall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com