Solar Spectrum Selective Absorbing Coating and Its Preparation Method and Application

A technology that absorbs coatings and solar spectrum, applied in coatings, solar thermal devices, solar thermal power generation, etc., can solve the problems of high preparation cost, easy to be oxidized, etc., to achieve improved mechanical properties, not easy to release film, low thermal radiation rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

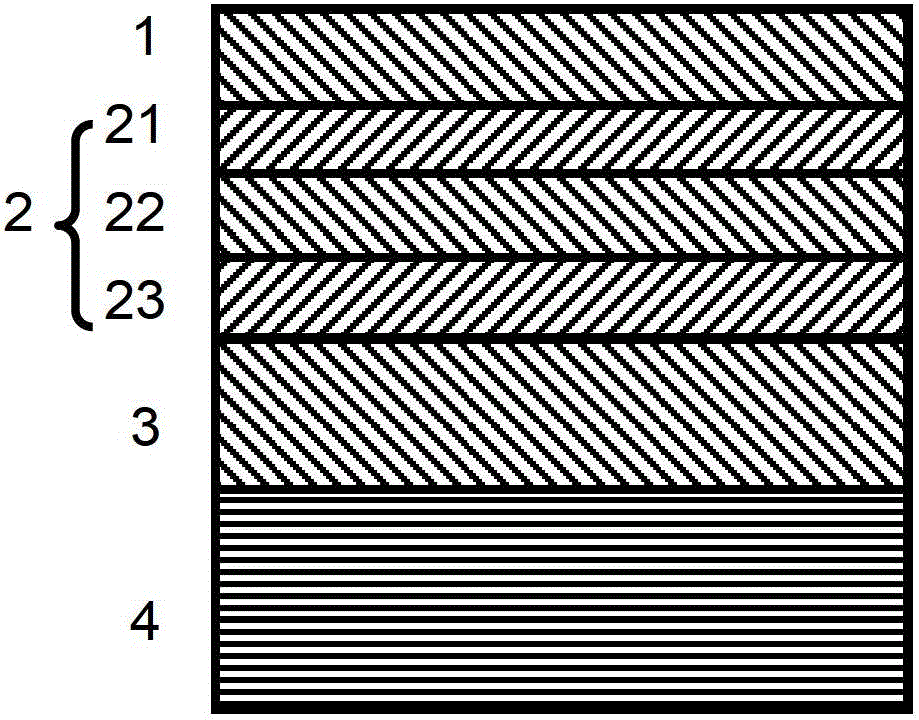

[0037] The preparation of the absorbing layer is to prepare the internal absorbing layer on the above-mentioned infrared reflective layer by reactive magnetron sputtering, using metal titanium as the target material, and feeding 50sccm argon and 8sccm nitrogen to make TiN with a thickness of 20nm-50nm x1 o y1 The internal absorption layer of the material; then pass into 2-2.5sccm oxygen, continue to use metal titanium as the target material to prepare the medium absorption layer on the above-mentioned internal absorption layer by the reactive magnetron sputtering method, and the thickness of the medium absorption layer is controlled at 10 -50nm, the material of the middle absorbing layer is TiN x2 o y2 Then increase the flow rate of oxygen to 2.5-3.5sccm, continue to use metal titanium as the target material to prepare an outer absorbing layer on the above-mentioned middle absorbing layer by reactive magnetron sputtering, the thickness of the outer absorbing layer is controll...

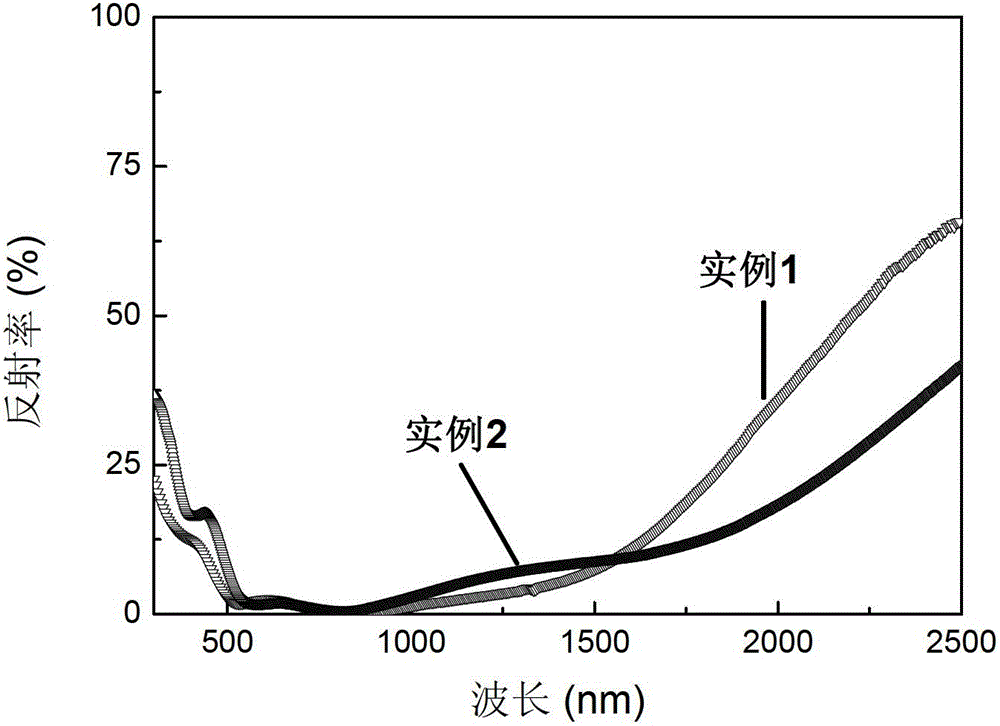

example 1

[0043] Carry out following operation steps according to above-mentioned preparation method:

[0044] 1) Carry out radio frequency ion cleaning to the glass base layer, remove the surface contamination layer and oxide layer, and increase the surface activity of the base;

[0045] 2) Transfer the base layer to the front of the aluminum target until the background vacuum is better than 6×10 -6 After Torr, pass into 50sccm argon gas, control pressure is 5mTorr, open sputtering power supply, keep power 1200W, set transfer rate as 0.4m / min, make base layer pass aluminum target 12 times, in order to prepare infrared reflective aluminum layer;

[0046] 3) Transfer the base layer coated with a metal aluminum layer to the front of the titanium target, inject 50 sccm argon gas, 8 sccm nitrogen gas, control the air pressure 5mTorr, turn on the sputtering power supply, keep the power at 1000W, and the transfer rate is 0.4m / min, so that the base layer Through the titanium target 3 times to...

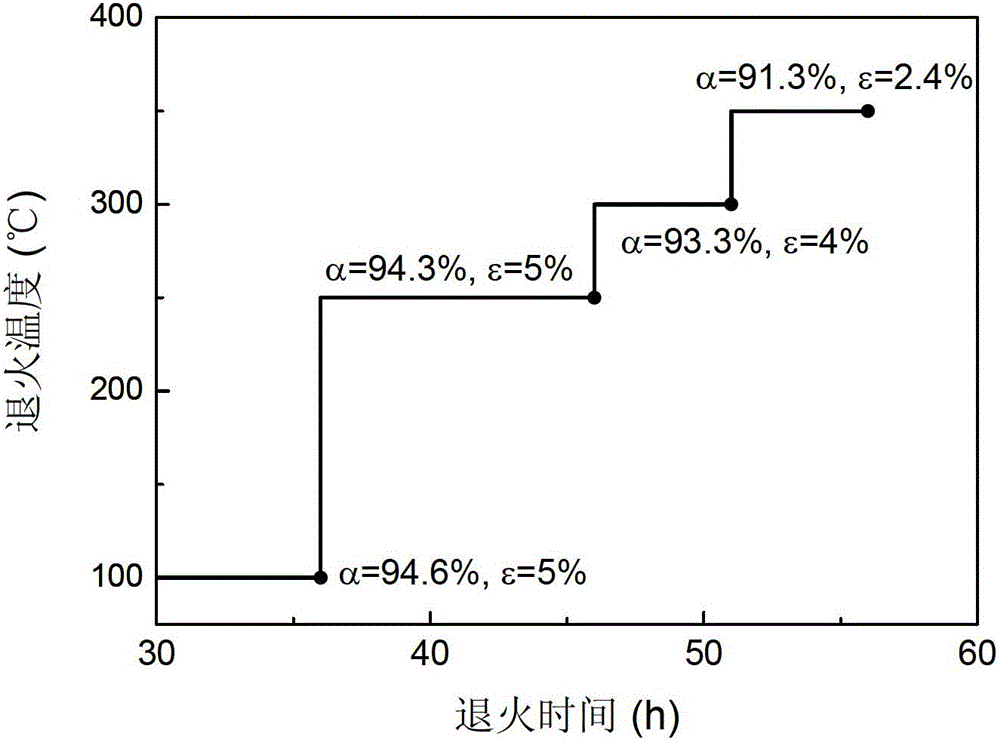

Embodiment 2

[0054] Carry out following operation steps according to above-mentioned preparation method:

[0055] 1) Carry out radio frequency ion cleaning on the Al base layer to remove the surface contamination layer and oxide layer, and increase the surface activity of the base. The thermal emissivity of the Al plate after sputtering cleaning is lower than 1.7%. At this time, the Al base layer has an infrared reflective layer at the same time role;

[0056] 2) The base layer is transported to the front of the magnetron sputtering titanium target, and the background vacuum is better than 6×10 -6 After Torr, feed 50sccm argon, 8sccm nitrogen, control the air pressure at 5mTorr, turn on the sputtering power supply, keep the power at 1000W, and the transmission rate at 0.4m / min, so that the base layer passes through the titanium target 3 times to prepare TiN. 0.94 o 0.60 internal absorption layer;

[0057] 3) Under the condition that other parameters remain unchanged, 2sccm of oxygen is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com