Scroll compressor

A technology of scroll compressors and moving scrolls, applied in the direction of rotary piston machinery, rotary piston pumps, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

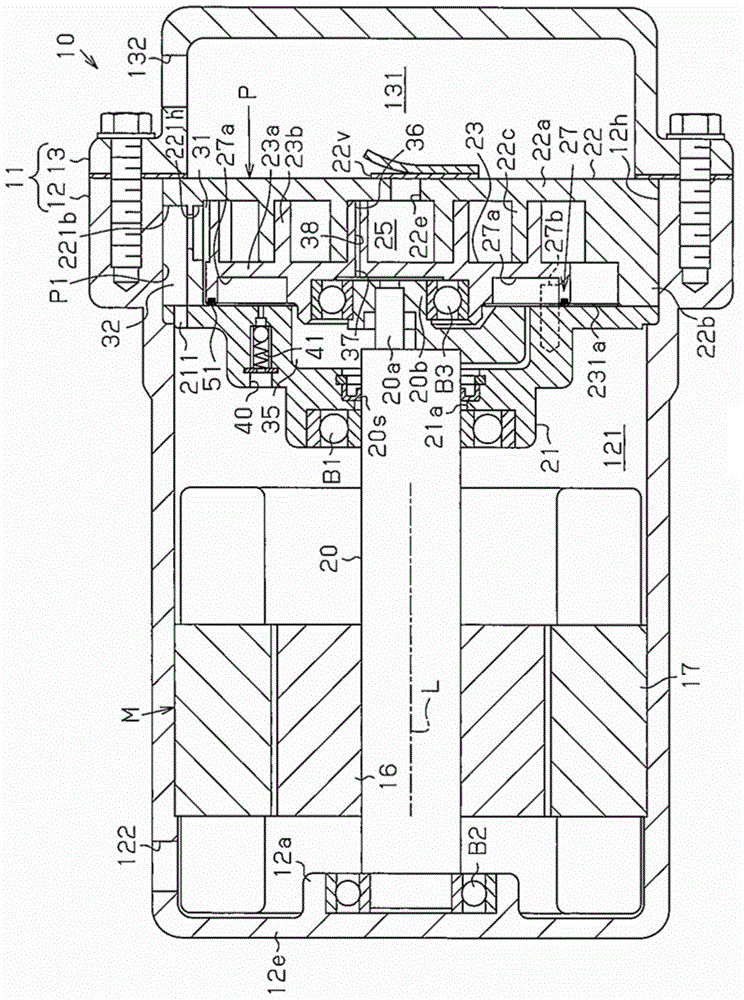

[0021] refer to Figure 1 to Figure 3 , one embodiment of a scroll compressor (hereinafter referred to as a compressor) will now be described. The compressor is installed in the vehicle and is used with the vehicle's air conditioner.

[0022] Such as figure 1 As shown in , a scroll compressor 10 includes a housing 11 made of metal (aluminum in this embodiment). The housing 11 includes a cylindrical motor housing member 12 and a cylindrical discharge housing member 13 . The motor housing member 12 includes a closed end and an open end 12h (left end as viewed in the figures). A discharge housing member 13 having a closed end is connected to the open end 12 h of the motor housing member 12 . The motor case member 12 accommodates the compression unit P that compresses refrigerant and the electric motor M that drives the compression unit P. As shown in FIG.

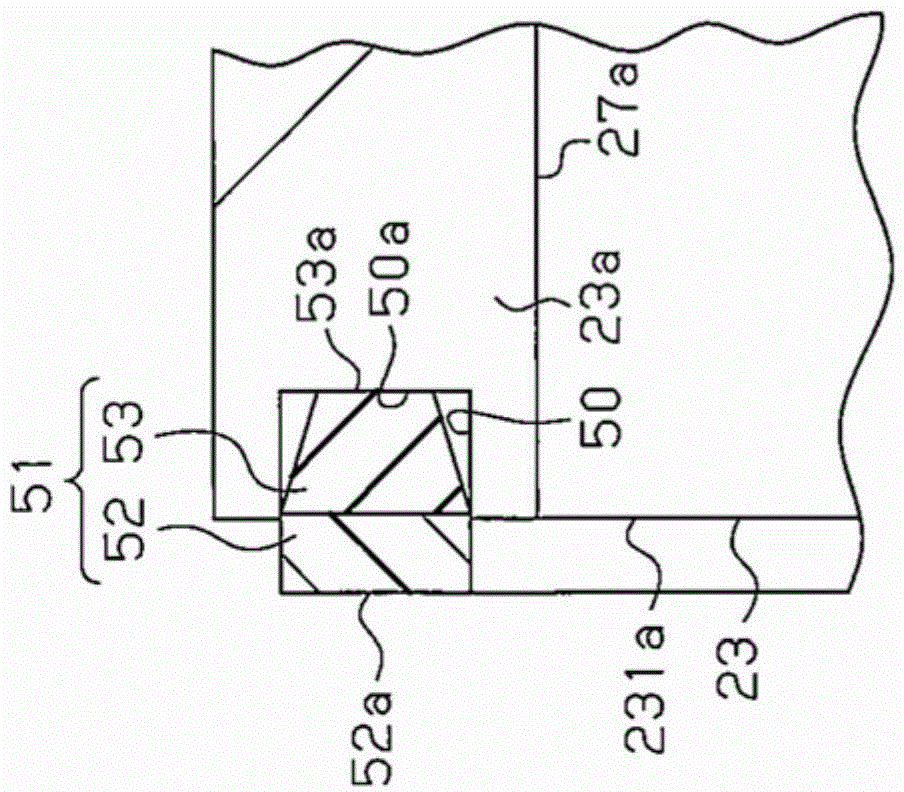

[0023] The motor housing member 12 includes an end portion 12e and a cylindrical shaft support portion 12a protruding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com