Flexible coupler transmitting torque by mooring ropes and engine applying same

A technology for flexible couplings and torque transmission, which is applied in the direction of elastic couplings, machines/engines, engines, etc., and can solve the problem that a single cable cannot transmit large torques

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

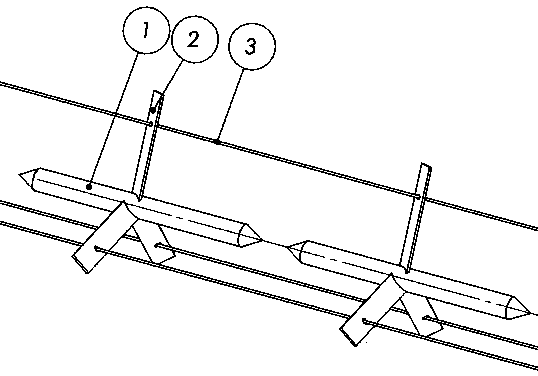

[0024] Embodiment 1: as figure 1 As shown in the figure, the engine of the cable transmission torque in the form of a water turbine includes a buoy (1), a horizontal blade (2), and a cable (3); the horizontal blade (2) is connected to the buoy (1), and the cable (3) tightens the front and rear The blades (2) on the adjacent buoys (1) are connected.

[0025] When the engine is placed in a river or ocean current, the direction of the water flow is approximately parallel to the axis of the buoy (1), the buoy (1) is hollow or filled with light foam material inside, and the three transverse blades (2) are impacted by the water flow and rotate to produce Torque, the three cables (3) transmit the torque, the torque is transmitted to the generator on the shore or on the mother ship, and the generator is driven to rotate and generate electricity.

[0026] The buoy (1) can be hollow or filled with lightweight foam material.

[0027] The cable (3) can be a steel wire rope, a hemp rope...

Embodiment 2

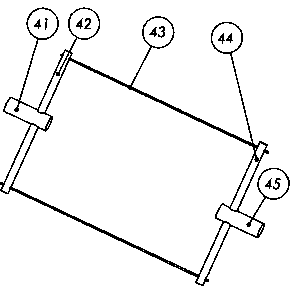

[0031] Embodiment 2: as figure 2 As shown, the motor of the cable transmission torque in the waterwheel form includes a buoy (21), a longitudinal blade (22), a cable (23), a reinforcing rib (24); the longitudinal blade (22) is connected to the buoy (21), Cable (23) connects the longitudinal blades (22) on the buoys (21) next to each other left and right.

[0032] When the engine is placed in a river or ocean current, the direction of the water flow is roughly perpendicular to the axis of the buoy (21), the buoy (21) is hollow or filled with light foam material, and the three longitudinal blades (22) are impacted by the water flow and rotate to produce Torque, the three cables (23) transmit the torque, the torque is transmitted to the generator on the shore or on the mother ship, and the generator is driven to rotate and generate electricity.

[0033] The buoy (21) can be hollow or filled with lightweight foam; the cable (23) can be steel wire rope, hemp rope, cable, etc., or...

Embodiment 3

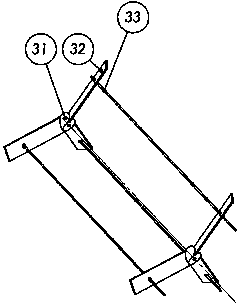

[0037] Embodiment 3: as image 3 As shown, the windmill-form cable transmits a high-torque wind engine, including a central shaft (31), wind blades (32), and cables (33); the wind blades (32) are connected to the central shaft (31), and the cables (33 ) connect the wind blades (32) on the central shaft (31) next to each other front and rear.

[0038] The engine flies in the wind like a kite, and the center of the central shaft (31) is provided with a round hole, which can be threaded through a cable or connected to a conventional kite or a light balloon through a swivel to assist in increasing the lift. The three wind blades (32) receive wind The propulsion to rotate generates torque, which is transmitted by three cables (33), which are transmitted to a generator mounted on the ground.

[0039] When the distance between the front and rear two wind blades (32) is smaller than the distance between two adjacent central tubes (31), there is no possibility of the cables being enta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com