Production process of flame retardant trim cow leather

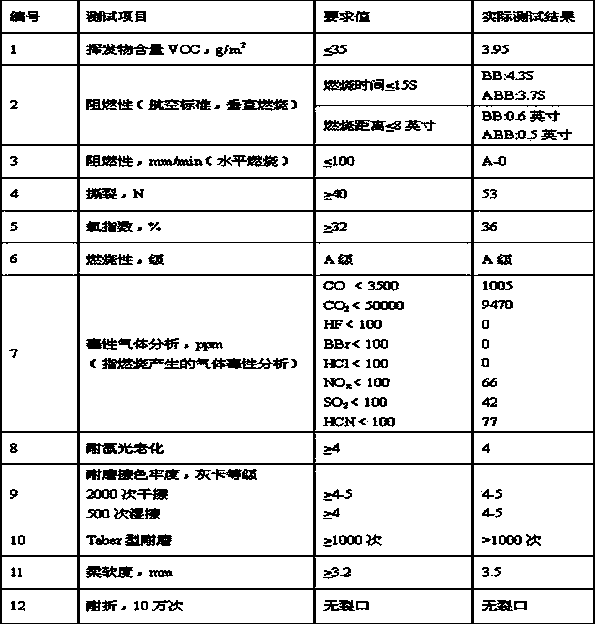

A production process, a flame-retardant technology, applied in the production process of cowhide interior leather, can solve the problems of affecting the life safety of passengers, affecting the air quality in the car, and immediately extinguishing, so as to achieve low flammability and improve the relatedness of finished leather. Physical properties, effect of content reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] After the cowhide is fleshed, delimed, and washed with softening water, the liquid ratio is 30%; taking the hide as 100 parts by mass, add 30 parts of water, control the temperature at 20°C, add 6 parts of sodium chloride, and control the Baumé degree 6.5, After reacting for 20 minutes, add 0.3 parts of 10wt% dilute formic acid, add 0.4 parts of 10wt% dilute formic acid after 10 minutes, add 0.8 parts of 5wt% dilute sulfuric acid after reacting for 10 minutes, and then use the same Add sulfuric acid 2 times in the same way, and react for 10 minutes each. After the third dilute sulfuric acid is added, the pH value is controlled at 2.3 and then reacted for 60 minutes, and then the pH value is controlled at 3.0, and the reaction is continued for 45 minutes to complete pickling; Add 5 parts of chromium powder into the pickling skin drum, react for 60 minutes, control the temperature at 24°C, and control the pH value at 2.5, then add 0.5 parts of magnesium oxide Blancorol HR-...

Embodiment 2-5

[0024] After the cowhide is fleshed, delimed, and washed with softening water, the liquid ratio is 30%; taking the hide as 100 parts by mass, add 30 parts of water, control the temperature at 20±2°C, add 6 parts of sodium chloride, and control the wave Mido 6.0~7.0, after reacting for 20 minutes, add 0.3 parts of 10wt% dilute formic acid, add 0.4 parts of 10wt% dilute formic acid after 10 minutes, add 0.8 parts of 5wt% diluted sulfuric acid after reacting for 10 minutes, and react for 10 minutes Then add sulfuric acid twice in the same way, and react for 10 minutes each. After the third dilute sulfuric acid is added, the pH value is controlled at 2.3 for another 60 minutes, and then the pH value is controlled at 3.0±0.1, and the reaction is continued for 30~60 minutes. Minutes to complete pickling; add 5 parts of chromium powder to the above pickling skin drum, react for 60 minutes, control the temperature at 22~25°C, and control the pH value at 2.5±0.1, then add 0.5 parts of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com