Tool clamp of free rotating indexing table

An indexing workbench and clamping technology, which is applied in the direction of manufacturing tools, clamping, positioning devices, etc., can solve the problems of occupying assembly component resources, long assembly time, and difficult manufacturing of ratchet plates, etc., to achieve convenient movement and shorten the auxiliary time. time, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

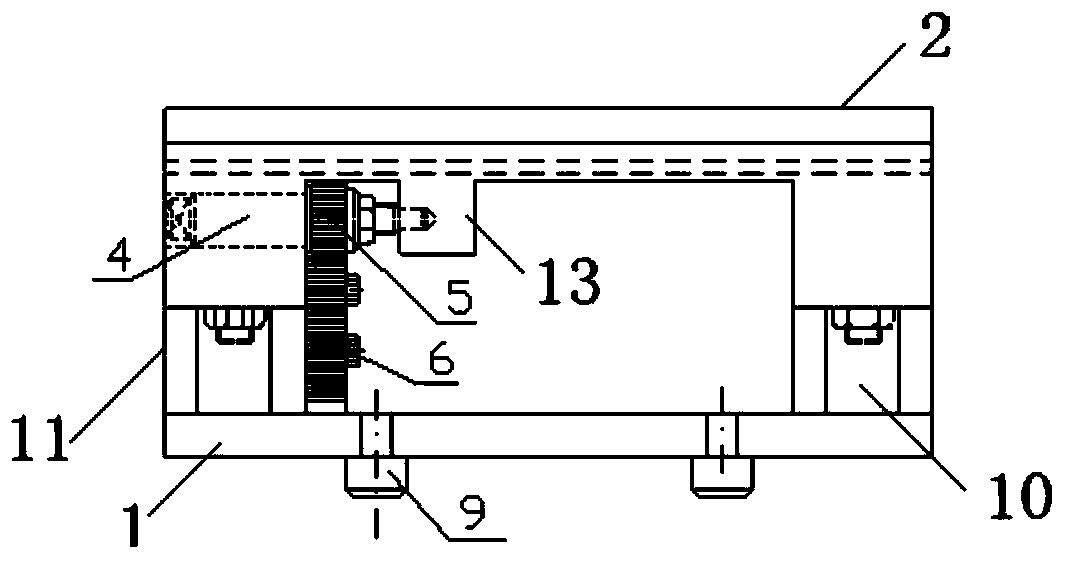

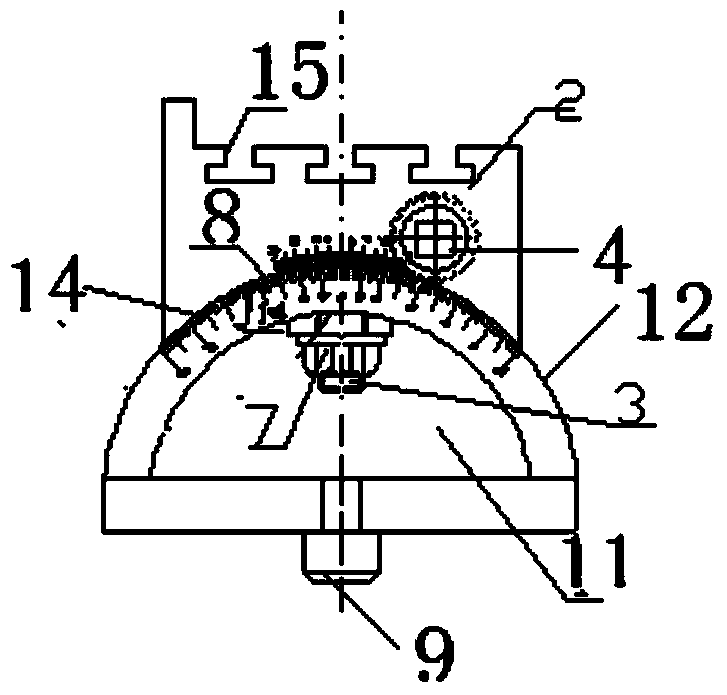

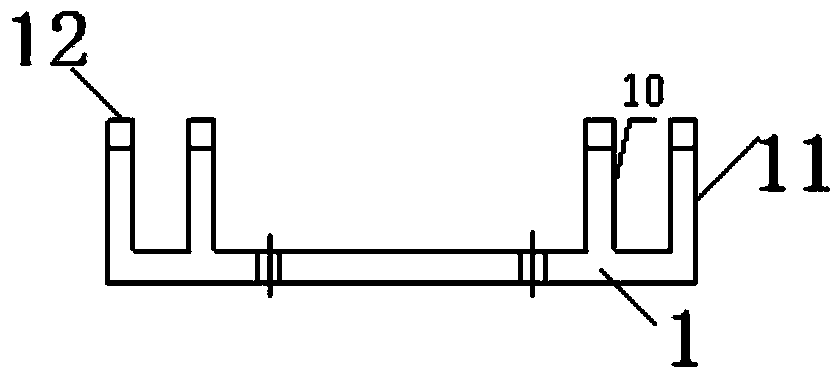

[0016] refer to Figure 1-Figure 4 . In the embodiments described below, any rotary indexing workbench fixture includes: a mounting base 1 that can be fastened to the worktable of a machine tool and an indexing workbench 2 mainly used for clamping processing parts. On the vertical plates 11 on both sides of the symmetrical distribution of the mounting seat 1, there are guide rail grooves 10 mainly used for guiding the sliding block 3 to locate and slide. The bottom arcs 14 at both ends of the indexing table 2 are assembled on the above-mentioned top arcs 12 in the same arc. Mounting seat 1 vertical plate 11 one side top surface circular arc 12 end surface is engraved with the dial 8 that divides uniform scale line from 0 °~50 ° equally, and these scales can play the required angle of fast adjustment parts. The center of the bottom plate of the mounting seat 1 is formed with 2 fastening holes that can be pressed into the mounting screw pins 9, and the mounting screw pins 9 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com