Electrical discharge machining level-by-level self-adaptive fuzzy control method of metal-ceramic functionally graded material

A functionally graded material, self-adaptive fuzzy technology, applied in metal processing equipment, electric processing equipment, circuits, etc., can solve the problems of inability to machine through holes, different discharge characteristics and removal mechanisms, etc., to overcome the unstable discharge state, overcome the The ceramic layer is difficult to machine, and the effect of improving the effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

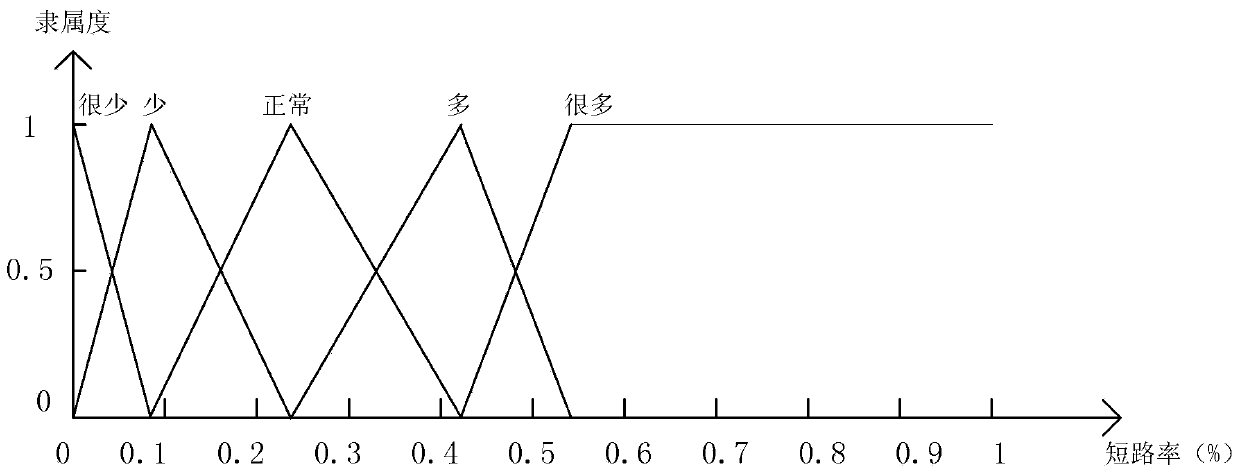

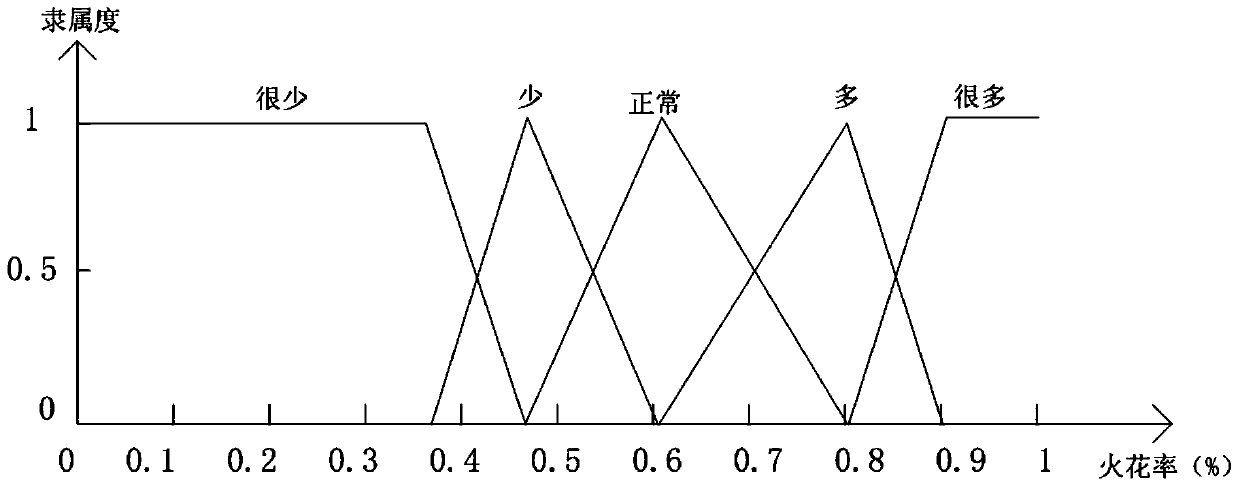

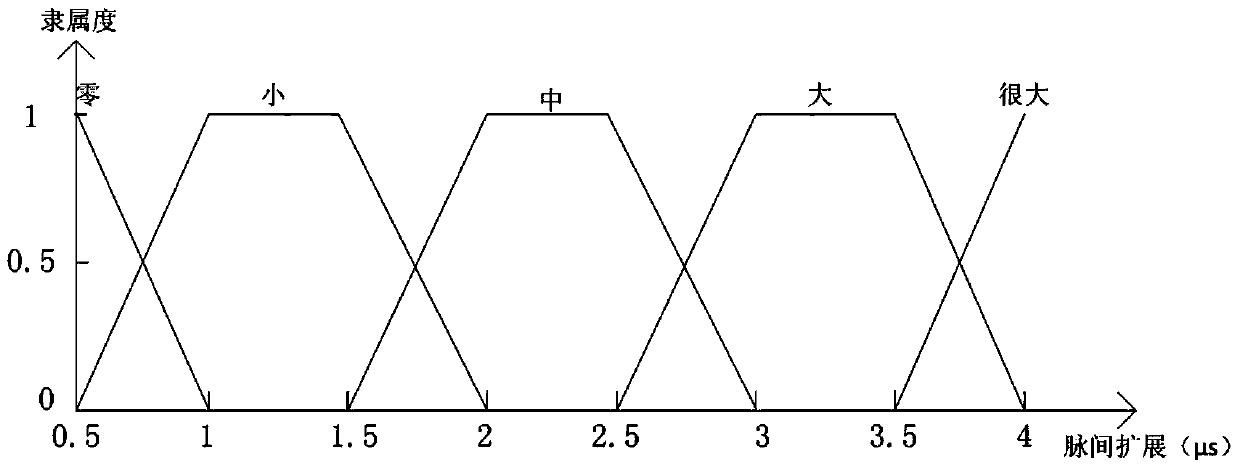

[0025] A step-by-step self-adaptive fuzzy control method for metal-ceramic functionally graded material electric discharge machining, the metal-ceramic functionally gradient material is a multi-layer composite functionally gradient material composed of a metal layer, a gradient layer and a ceramic layer, and the first processing starts Layer material is conductive metal layer; Described control method utilizes fuzzy controller model to realize, and fuzzy controller model is input quantity with short-circuit rate and spark rate, and pulse-to-pulse extension and speed variation are output quantities, and described input, output The membership interval of the quantity is:

[0026] Short circuit rate ∈ [0,1];

[0027]spark rate ∈ [0,1];

[0028] Intervein extension ∈ [0.5,4];

[0029] Speed change ∈ [-2,2];

[0030] The process of using the fuzzy controller model to perform adaptive fuzzy control on metal-ceramic functionally graded material EDM is as follows: set the initial...

specific Embodiment approach 2

[0032] The difference between this implementation and the first implementation is that the pulse power supply is a transistor-controlled RC pulse power supply, and other steps are the same as the first implementation.

[0033] Figure 7 It shows the comparison between the step-by-step adaptive fuzzy control strategy and the conventional control method for the processing of metal-ceramic functionally graded materials: the conventional control method cannot form a stable conductive film when processing the ceramic layer due to the fixed processing parameters in the process of processing the hole. Successfully process through-holes on metal-ceramic functionally graded materials. Using the step-by-step adaptive fuzzy control strategy, the optimal combination of parameters can be carried out according to the characteristics of different material layers. When the gradient layer and ceramic layer with high ceramic composition content are processed, a stable conductive film can be for...

Embodiment

[0046]

[0047] The workpiece is connected to the positive pole of the power supply, and the tool electrode is connected to the negative pole of the power supply. The workpiece, tool electrode and power supply form a discharge circuit during processing. Under the same initial processing conditions, the conventional EDM control method and the step-by-step adaptive fuzzy control method were used to carry out machining comparison experiments. from Image 6 It can be clearly seen from the discharge waveform diagram that the conventional EDM control system in Ni-Al 2 o 3 In the processing of functionally graded materials, only relying on the simple average voltage method for servo control, there will be a large number of abnormal discharge waveforms in the processing waveform (such as Image 6 As shown in a), the abnormal discharge state will directly affect the stability and processing efficiency of EDM. The use of step-by-step adaptive fuzzy control will improve the abnorma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com