Novel tinsmith snips

A new type of metal shearing technology, applied in shearing machine equipment, shearing devices, hand-held metal shearing equipment, etc., can solve the problems of not being suitable for cutting steel wires, single function of metal shearing, and abrasion on the inside of fingers, etc. Protection from abrasion, improved safety, and various functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

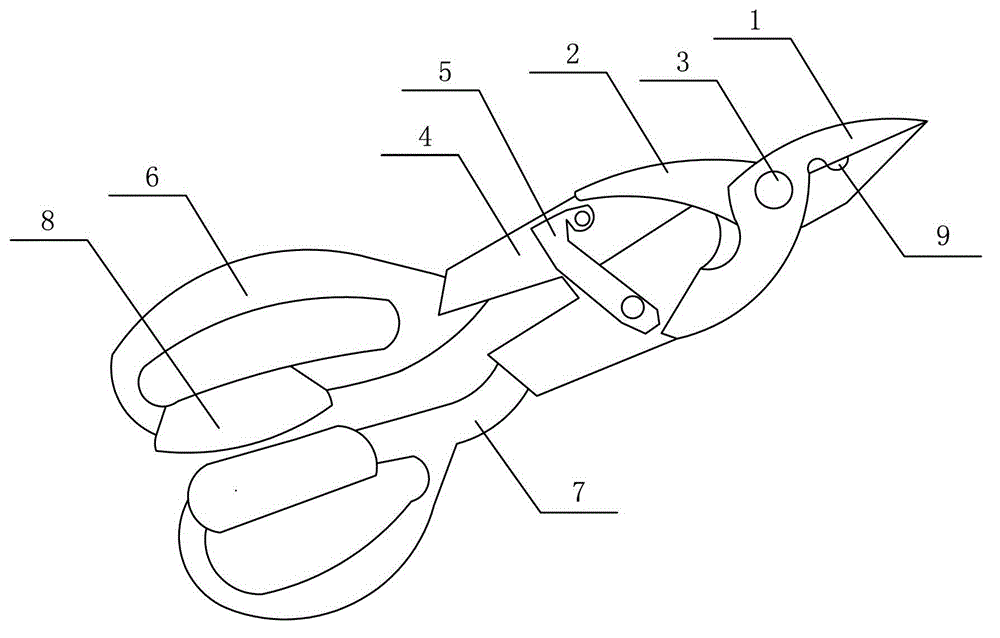

[0008] refer to figure 1 , the specific embodiment adopts the following technical solutions: it includes a shearing head 1, a connection extension handle 2, a pin 3, a rear end connection handle 4, a safety buckle 5, a left semicircle handle 6, a right semicircle handle 7, a finger protection cover 8 and Corrugated jaw 9, the cutting head 1 is connected to the connection extension handle 2, and the cutting head 1 and the connection extension handle 2 are fixed by the pin 3, the rear end of the connection extension handle 2 is connected to the rear connection handle 4, and the two rear ends are connected to the handle 4 are fixedly provided with a safety buckle 5, the rear end of the rear end connecting handle 4 is respectively connected with the left semicircular handle 6 and the right semicircular handle 7, and the inner side of the left semicircular handle 6 and the right semicircular handle 7 is provided with a finger protection cover 8, And the inner side of the rear end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com