Ceramic shell filtering device integrated with filters

A filter device, ceramic type technology, applied in the directions of filtration and separation, casting molding equipment, casting molds, etc., can solve the problems of filter crushing, high filtration cost, and high production cost, and achieve the effect of simplifying installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

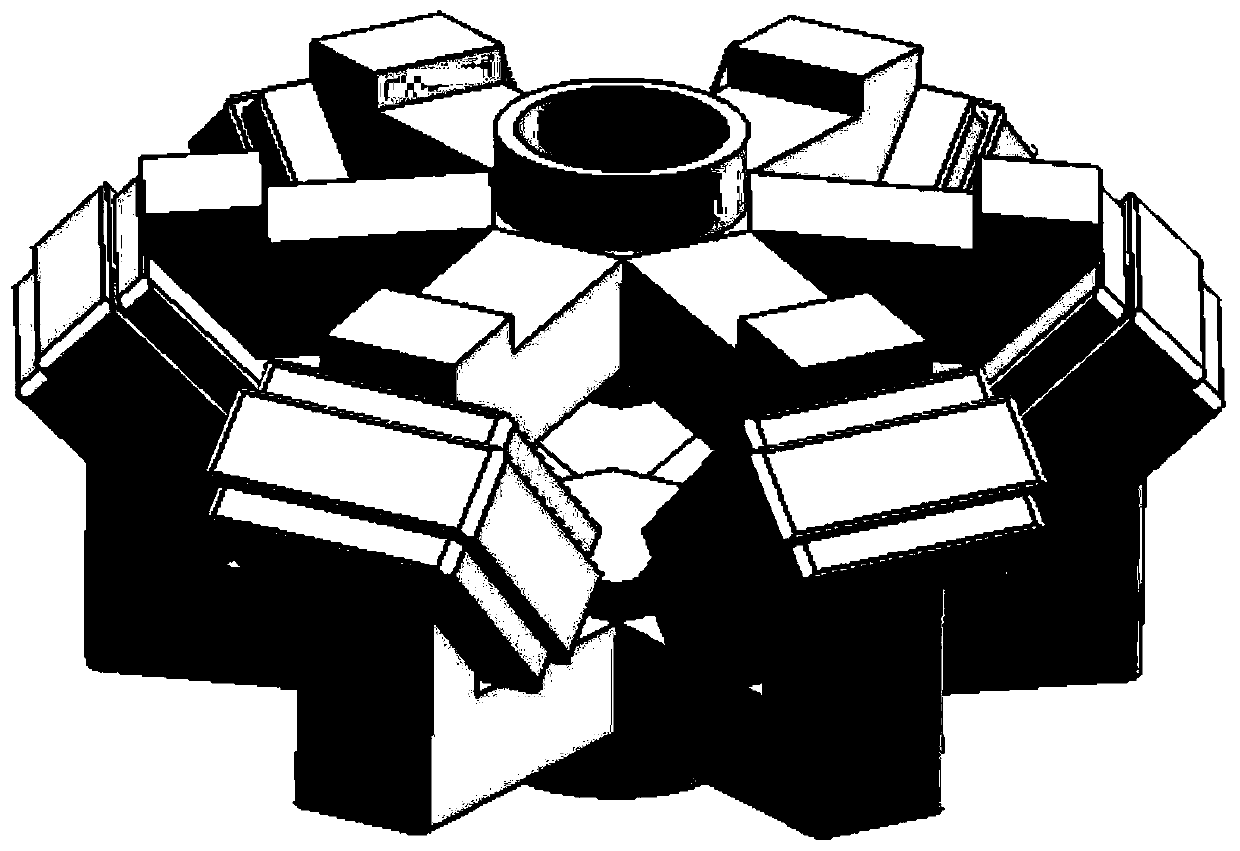

[0025] Such as figure 1 with 2 As shown, the main body of the filter device is a ceramic shell 1, which forms a cavity, the cavity includes a diversion part 1-2, a confluence part 1-7 and a C-shaped sprue in the middle, wherein the confluence part 1-2 is located in the upper part of the shell, and the upper end is the inlet of the filter device; the diversion part 1-7 is located in the lower part of the shell, and the lower end is the outlet of the filter device; the C-shaped sprues in the middle are connected in parallel, each connected between the diversion part and the confluence part Between, a filter 2 is set in each C-shaped runner. In the present invention, the diversion part 1-2 is equivalent to the main pipe, and the multiple C-shaped runners are equivalent to branch pipes, and each branch pipe divides and filters the molten metal from the main pipe, and then gathers it to the confluence part 1-7.

[0026] In this preferred embodiment, as shown in the figure, the C-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com