A heterogeneous catalytic ozone oxidation decontamination technology based on enhanced ozone adsorption and its application

A heterogeneous catalysis and ozone oxidation technology, which is applied in metal/metal oxide/metal hydroxide catalysts, oxidized water/sewage treatment, physical/chemical process catalysts, etc., can solve the problems of unfavorable separation and improve ozone transmission mass efficiency, enhanced removal and efficient mineralization, enhanced solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

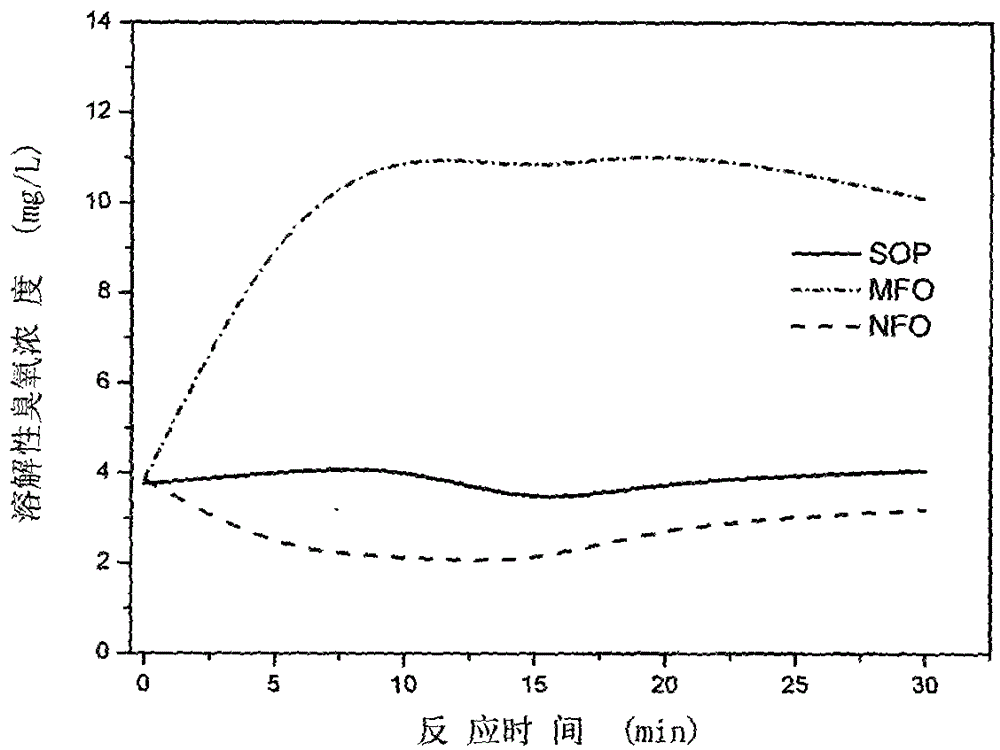

Image

Examples

Embodiment approach

[0018] The preparation steps of the ferromanganese spinel catalyst will be described below in conjunction with specific embodiments, so as to further understand the invention. The technical solution of the present invention is not limited to the specific embodiments listed below, but also includes any combination of the specific embodiments.

specific Embodiment approach 1

[0019] Specific embodiment one: the preparation method of ferromanganese spinel catalyst is carried out as follows

[0020] (1) Accurately weigh 6.275g Mn(NO 3 ) 2 4H 2 O and 20.2g Fe(NO 3 ) 3 9H 2 O, and dissolved in 100mL of deionized water, so that the solute is completely dissolved to obtain a clear solution, the above solution was stirred and dissolved for 0.5h;

[0021] (2) Accurately weigh 80g NaOH, and dissolve it completely with 250ml deionized water;

[0022] (3) to Mn(NO 3 ) 2 and Fe(NO 3 ) 3 Add 75mL NaOH solution dropwise to the mixed solution, and adjust the pH value of the mixed solution to between 7 and 8 to obtain a homogeneous suspension;

[0023] (4) Place the above suspension in a water bath and heat it to 90°C, and age at this temperature for 2h;

[0024] (5) Pour the supernatant of the above-mentioned aged solution, add distilled water and stir to clean the sediment, cover the bottle mouth and continue to precipitate for one hour, then measure ...

specific Embodiment approach 2

[0028] Specific embodiment two: the difference between this embodiment and specific embodiment one is that 20.2g (0.05mol) Fe(NO 3 ) 3 9H 2 O can be replaced by 20.000g (0.05mol) Fe 2 (SO 4 ) 3 or 8.110g (0.05mol) FeCl 3, other steps and parameters are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com