Process technology for turbulent wet-process flue gas desulfurization and desulfurization wastewater treatment

A wet desulfurization and flue gas technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, separation methods, etc., can solve problems such as insufficient chemical reaction, poor desulfurization effect, and poor mutual mixing , to achieve the effect of stable and reliable, excellent effect and easy operation and implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0039] The flue gas multi-stage turbocharged turbulent flow wet desulfurization device of the present invention will be described in detail below in conjunction with the accompanying drawings. As attached to the manual figure 2 Shown:

[0040] A flue gas multi-stage turbocharged turbulent wet desulfurization device, which consists of a sewage pipe 1, a supplementary desulfurizer inlet 2, a water pipe 3, a body 4, a flue gas inlet 5, a nozzle 6, a first-stage turbocharged turbulator 7, a Stage nozzle 8, receiving tank 9, stage 2 turbocharger turbulator 10, stage 2 nozzle 11, water nozzle 12, demister 13, flue gas outlet 14, water inlet pipe 15, stage 2 desulfurizer inlet 16, stage 1 desulfurizer Inlet 17, desulfurizer inlet 18, desulfurizer outlet 19, primary turbocharger turbulence device;

[0041] The flue gas multi-stage turbocharged turbulent flow wet desulfurization device has a flue gas inlet 5 at the lower part of the body 4, and a flue gas outlet 14 at the upper end ...

specific Embodiment approach 2

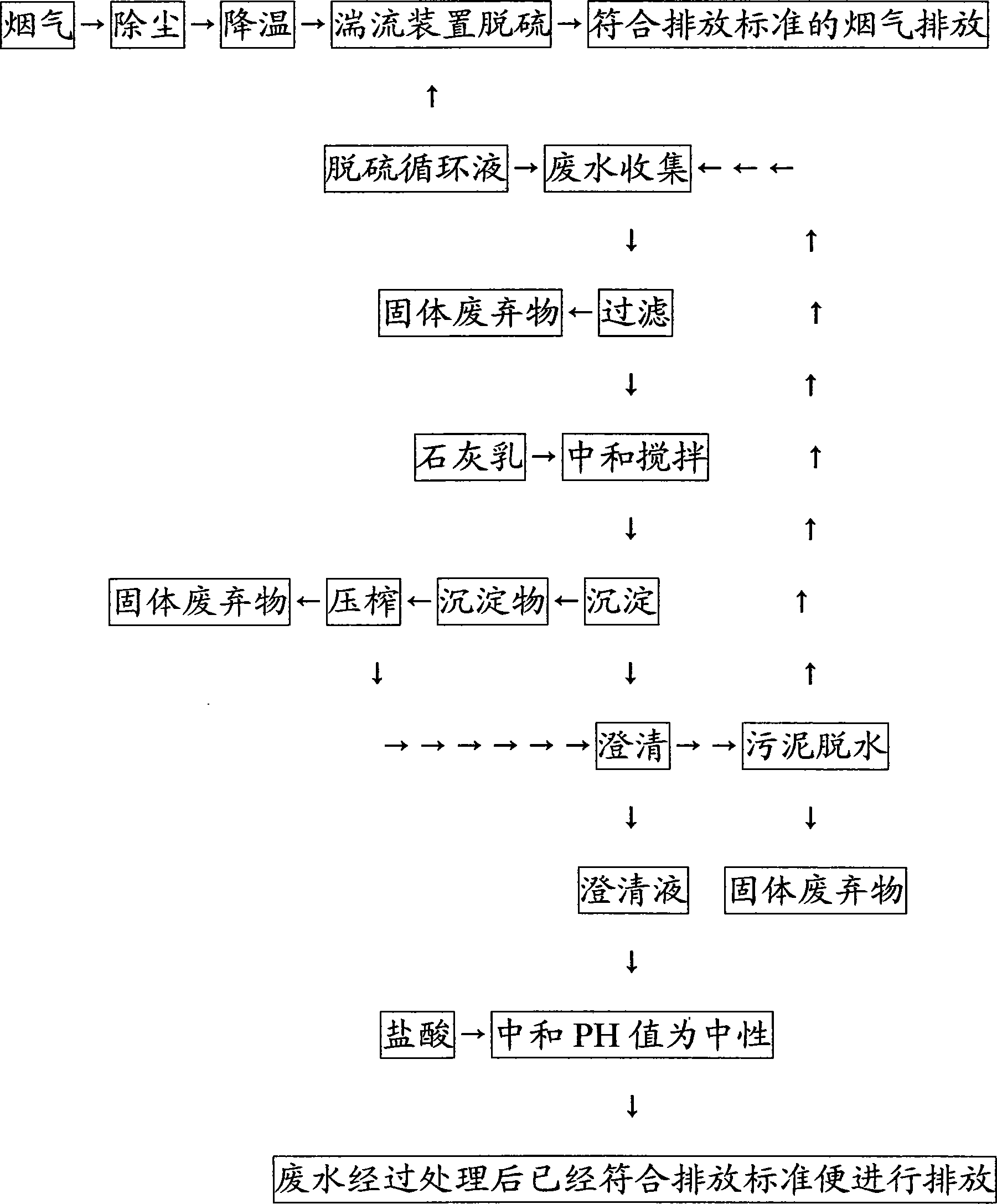

[0046] The following is a detailed description of the desulfurization wastewater treatment technology after flue gas turbulent flow wet desulfurization in the present invention in conjunction with the accompanying drawings. As attached to the manual figure 1 Shown:

[0047] A desulfurization wastewater treatment process technology for flue gas turbulent wet desulfurization, which is aimed at treating the waste water discharged after desulfurization from the flue gas multi-stage turbocharged turbulent wet desulfurization device described in the specific embodiment 1. Sulfur dioxide (SO) in flue gas 2 ) process, both the desulfurizing agent solution in the desulfurizing agent solution pool and the desulfurizing agent solution in the secondary desulfurizing agent solution pool have gone through multiple cycles, and the desulfurizing agent solution will accumulate a large amount of chloride ions after repeated cycles (Cl - ), heavy metal ions, and chloride ions will cause serio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com