Scraper plate apparatus of mud scraper

A technology of mud scraper and scraper, which is applied to the feeding/discharging device, chemical instrument and method, and separation method of the settling tank, which can solve the problems of high cost and easy wear of the scraper, and achieve low manufacturing cost , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

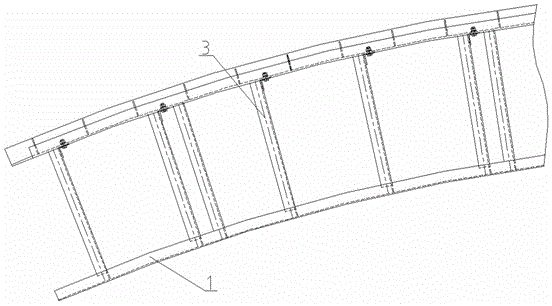

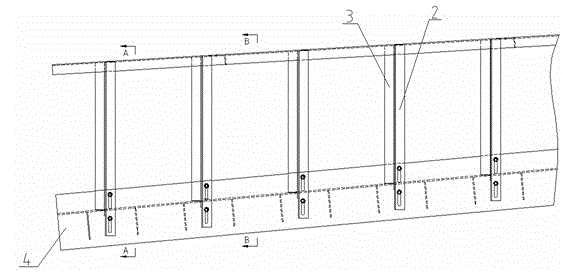

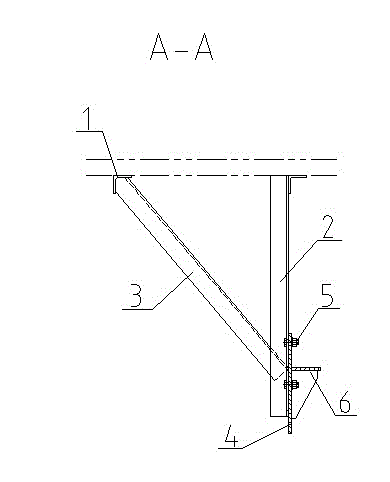

[0013] A scraper device for a mud scraper, comprising two side-by-side beams 1 welded to the bottom of a mud scraper truss, a hanging arm 2, an oblique support 3, and a scraper 4, and the hanging arm 2 is vertically welded to one of the beams 1 On the side, one end of the slanting support 3 is connected to another beam 1, and the other end of the slanting support 3 is connected to the lower end of the hanging arm 2. The lower end of the hanging arm 2 is provided with a waist-shaped long hole. The side of the scraper 4 is welded with a T-shaped support plate 6; a support plate 7 is provided between the two side-by-side beams 1; the number of waist-shaped long holes at the lower end of the hanging arm 2 is at least two.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com