Motor rotor end ring-guide bar medium-frequency induction brazing verifying tooling and method

An induction brazing and motor rotor technology, which is applied in the manufacture of stator/rotor body, etc., can solve problems such as unfavorable timely tracking and verification of rotor brazing quality, affecting mechanical performance test results, and cracking of end ring-bar brazing seams. , to achieve the effect of improving labor productivity and efficiency, saving verification costs, and shortening verification cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

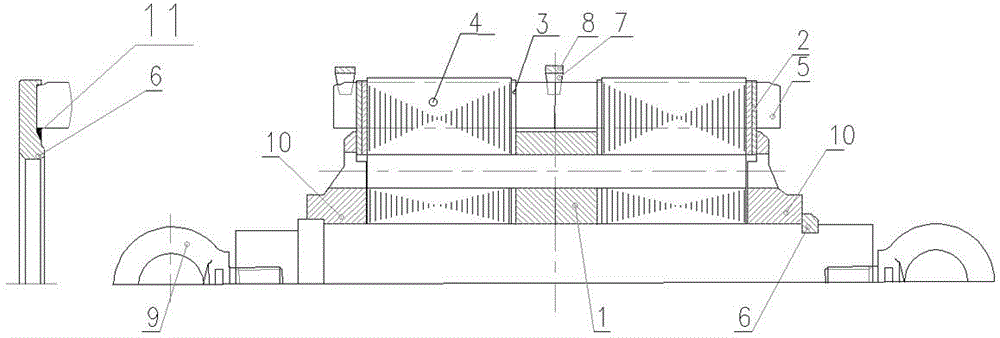

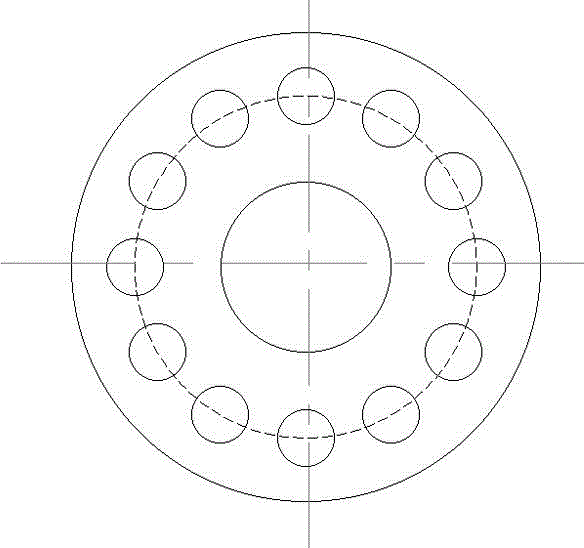

[0029] An intermediate frequency induction brazing verification tool for motor rotor end ring guide bar according to the present invention, such as figure 1 , figure 2 As shown, it includes rotor separator 1, rotor end plate I2 and rotor end plate II3. The rotor separator 1 is arranged in the middle of the rotor core punch 4, which separates the rotor core punch 4 and the guide bar 5 into two parts, realizing the split structure of the verification tooling. After adding the rotor separator, the local core punches are reduced, and the increase After brazing, the ring-guide bar joint assembly opens up the operating space to reduce the contact area between the guide bar and the iron core punch. The outer circumference of the guide bar 5 at the position of the rotor separator 1 is wrapped with asbestos cloth to realize the simulation brazing of the rotor verification tooling and the actual whole process. Consistency of heat loss and quality during brazing of Taiwan rotor product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com