Test device for testing contact characteristic of fixed junction surface of machine tool

A technology for fixing the joint surface and contact characteristics, which is applied in the field of the test device for testing the contact characteristics of the fixed joint surface of the machine tool. Precision and dynamics, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

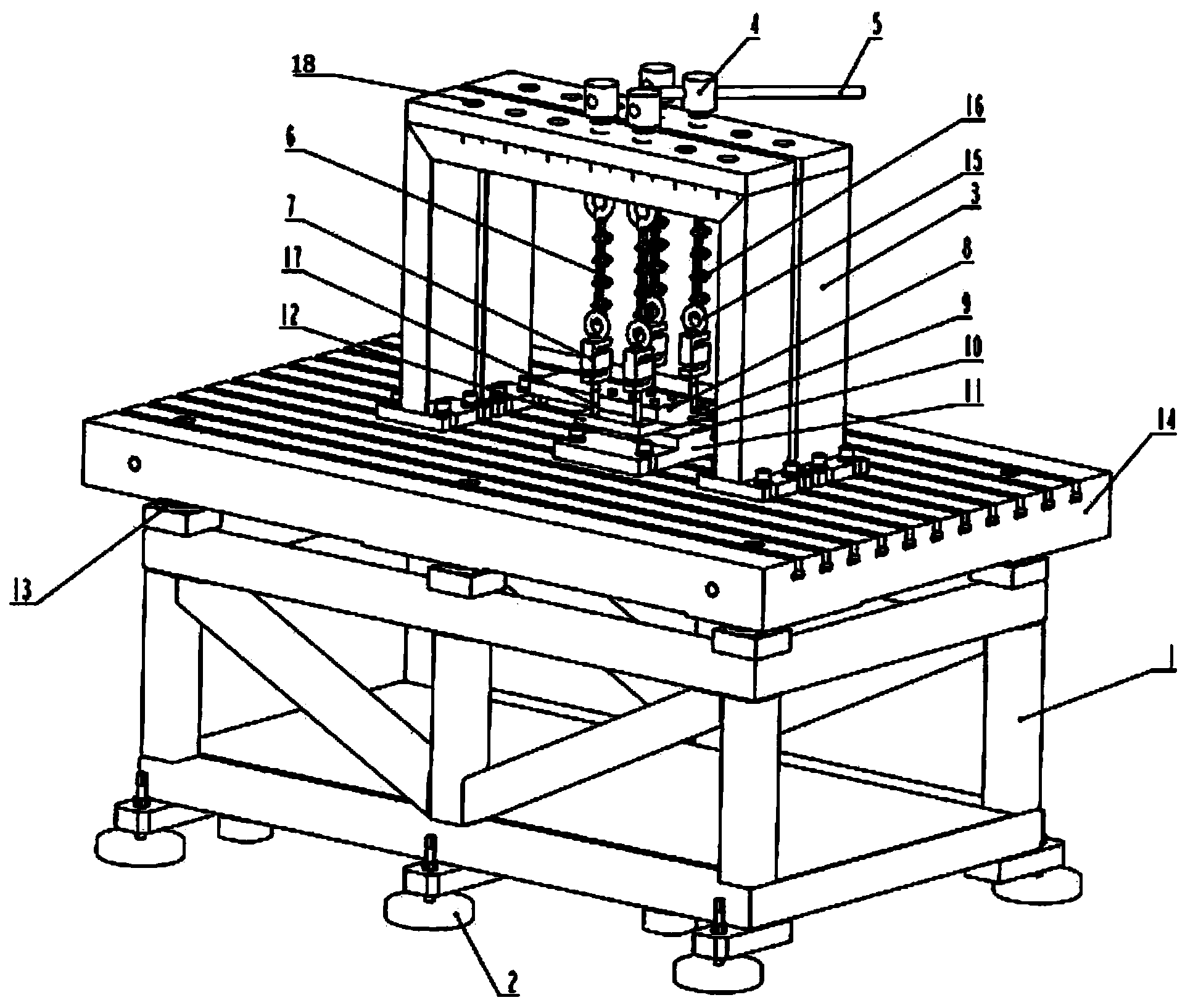

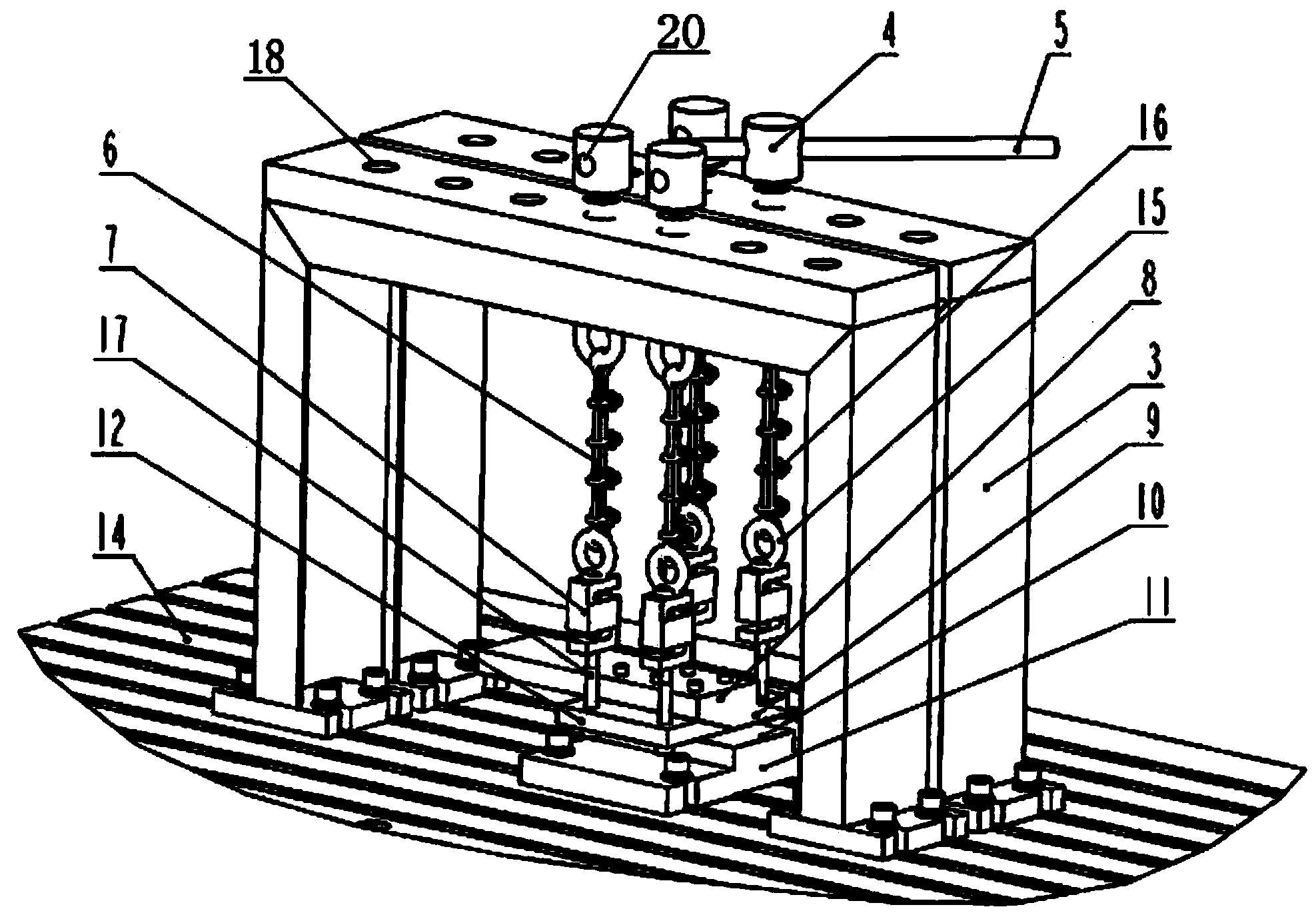

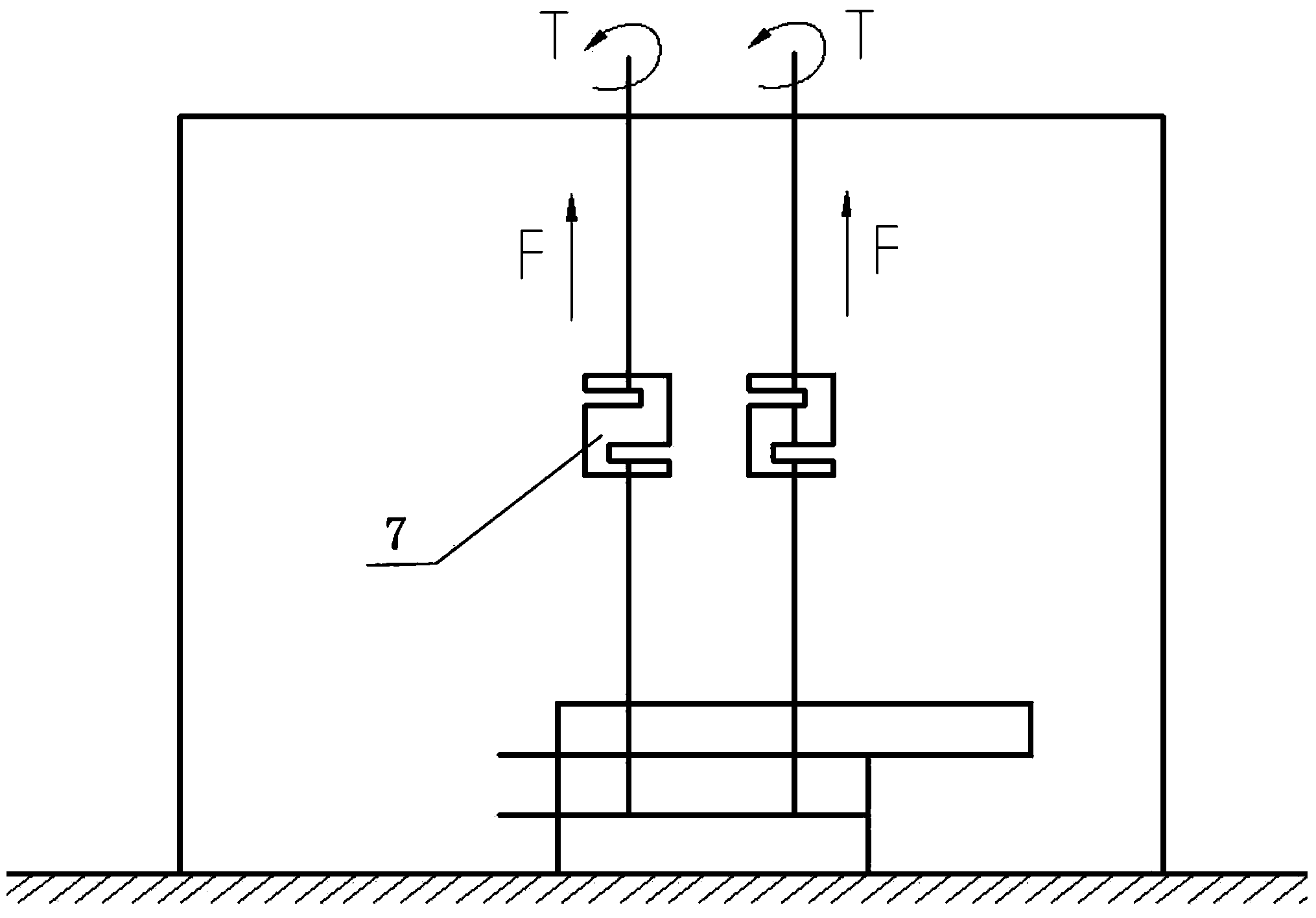

[0023] Such as Figure 1-4 As shown, a test device for testing the contact characteristics of the fixed joint surface of a machine tool includes a test bench body 1, a pressure-sensitive film I9 and a pressure-sensitive film II10, and a shock-absorbing shim 2 is arranged under the test bench body 1 to isolate the surrounding vibration source. The role of the test bench body 1 is provided with a T-slot table 14, a damping bolt 13 is provided between the T-slot table 14 and the test bench body 1, a loading bracket 3 is provided on the T-slot table 14, and a loading bracket 3 Several threaded through-holes 18 are equidistantly arranged at the top of the top, and the loading bolt 4 is placed in the threaded through-hole 18, and the head of the loading bolt 4 is provided with a through-hole 20, and the loading lever 5 is placed in the through-hole 20. The loading bolt 4 is screwed in or out to adjust the tension. The lower end of the loading bolt 4 is connected to the steel wire ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com