Heat insulation pipe joint structure

A technology of joint structure and thermal insulation pipe, applied in the direction of pipe/pipe joint/pipe fitting, pipeline protection through thermal insulation, pipeline protection, etc., can solve the problems of medium leakage, unable to guarantee the sealing effect, pipe joint falling off, etc., to improve the service life , good sealing and thermal insulation effect, and the effect of ensuring installation reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

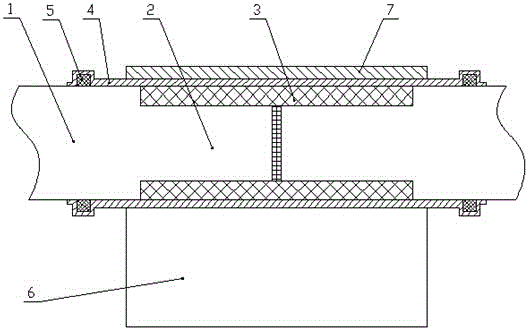

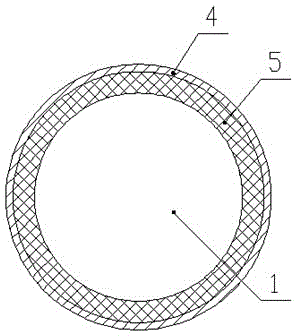

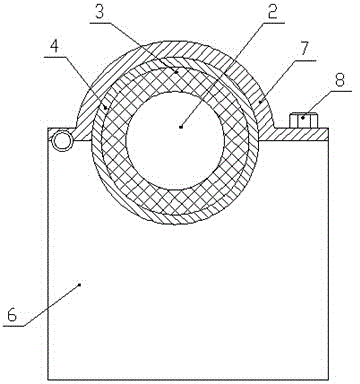

[0028] This embodiment provides a support structure for heat insulating pipe joints, such as Figures 1 to 3 As shown, the two insulated pipes both include a regular section 1 and a joint section 2 at the end of the regular section 1 , and the outer diameter of the joint section 2 is smaller than the outer diameter of the regular section 1 . The two heat-insulating pipes are butted through the joint section 2 and the outer periphery of the butt joint is covered with a heat-insulating sleeve 3 , and the outer peripheral surface of the heat-insulating sleeve 3 is flush with the outer peripheral surface of the conventional section 1 .

[0029] As a preferred manner, the two joint segments 2 are butted by coaxial welding.

[0030] As a preferred manner, the thermal insulation cover 3 is a polyurethane foam layer.

[0031] The outer circumference of the heat insulating sleeve 3 is covered with a sealing collar 4, the length of the sealing collar 4 is greater than the length of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com