Heat-dissipating device, balance control method and controller

A cooling device and controller technology, applied in pump control, pump devices, components of pumping devices for elastic fluids, etc., can solve the problems of reduced fan life, restricted equipment integration, and reduced fan life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

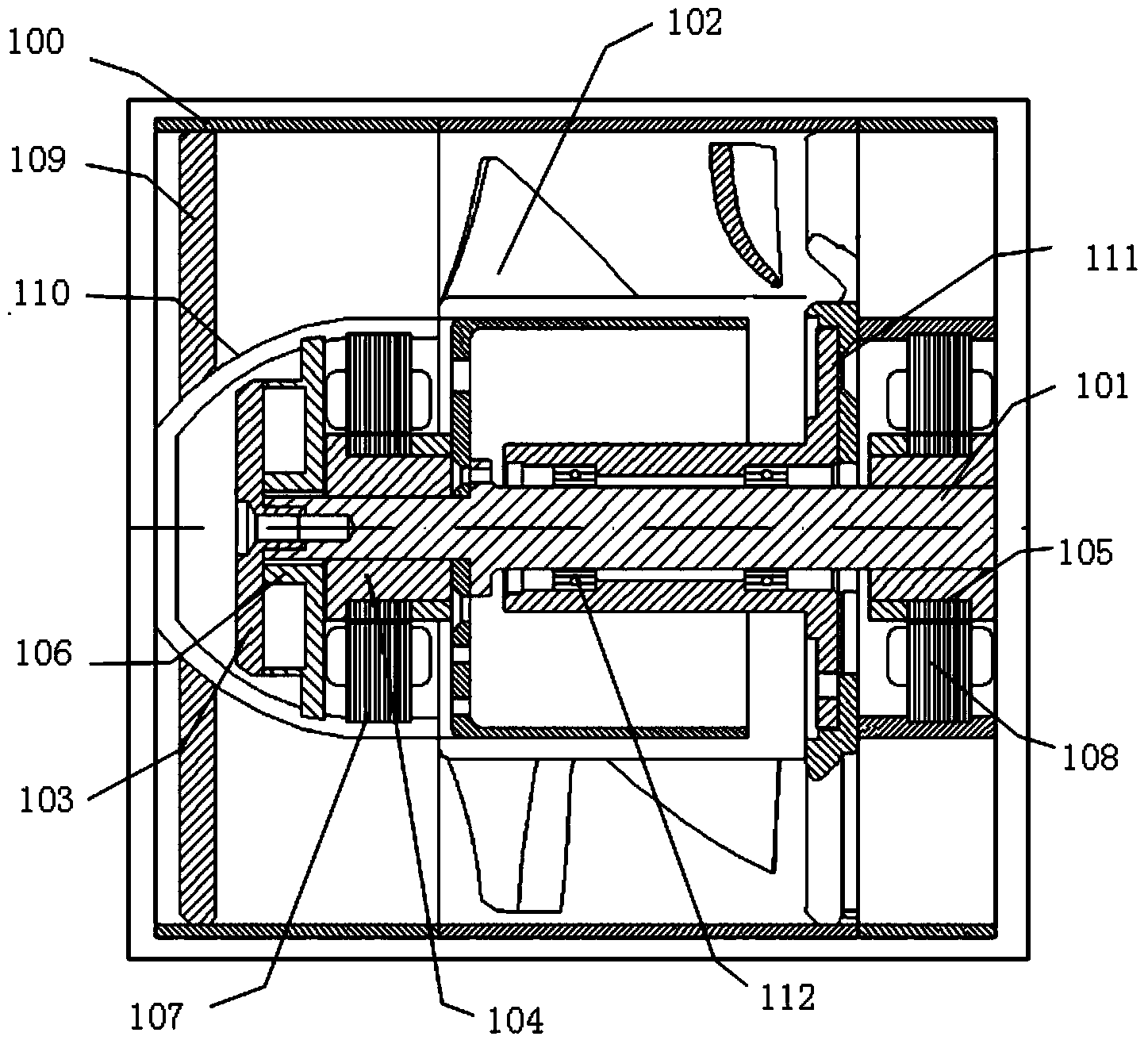

[0074] Embodiment 1. This embodiment provides a cooling device. For the specific structure of the cooling device, please refer to figure 1 as shown, figure 1 It is a schematic cross-sectional top view of a preferred embodiment of the heat dissipation device provided by the embodiment of the present invention.

[0075] Depend on figure 1 It can be seen that the cooling device includes a fan housing 100;

[0076] A driving device (not shown in the figure) is fixedly arranged in the fan casing 100;

[0077] Inside the fan casing 100, a motor shaft 101 is connected to the driving device, that is, the motor shaft 101 can rotate under the power supply of the driving device.

[0078] Wherein, the specific structure of the driving device is an existing technology, which is not limited in this embodiment, as long as the motor shaft 101 can be rotated by the driving device.

[0079] Connected with the motor main shaft 101, there are a plurality of rotors fixedly provided with fan bl...

Embodiment 2

[0106] Embodiment 2. In this embodiment, the specific structure of the heat dissipation device is further described in detail;

[0107] Please continue to see figure 1 As shown, the inside of the fan casing 100 of the heat dissipation device is also fixedly provided with a fan vane 109, which is used as a main load-bearing component in the fan casing 100, which can carry the motor shaft 101 and the rotor 103, The rotor 104 and the rotor 105.

[0108] The fan vane 109 is also used to form an air flow channel inside the fan housing 100 , that is, the fan vane 109 and the fan housing 100 are fixedly provided with a shroud 110 .

[0109] That is, the wind deflector 110 is provided with an accommodating groove, and one end of the motor spindle 101 can be inserted into the accommodating groove of the wind deflector 110 with a gap.

[0110] The wind deflector 110 is fixed in the fan housing 100 through the fan vanes 109 .

[0111] The flow direction of the specific cooling air is:...

Embodiment 3

[0144] Embodiment 3, the heat dissipation device provided by this embodiment can effectively protect the motor shaft and rotor when the motor shaft is powered off, so that the rotor and the magnetic bearing will not collide;

[0145] Please continue to see figure 1 as shown, figure 1 The heat dissipation device shown further includes a motor base 111 , and the motor main shaft 101 is fixedly arranged inside the fan housing 100 through the motor base 111 .

[0146] As long as the motor base 111 is sleeved on the motor main shaft 101 without the axial magnetic bearing and the radial magnetic bearing being sleeved therein, it is acceptable.

[0147] And the motor shaft 101 is in clearance fit with the through hole of the motor base 111 .

[0148] by figure 1 As shown as an example, the motor base 111 can be sleeved on the motor shaft 101 between the first radial magnetic bearing and the second radial magnetic bearing.

[0149] For the specific arrangement of the first radial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com