Oil-saving emission-reduction device for automobile

A technology for automobiles and fuels, used in machines/engines, internal combustion piston engines, engine components, etc., to solve problems such as filter burnout, emission reduction, filter rupture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

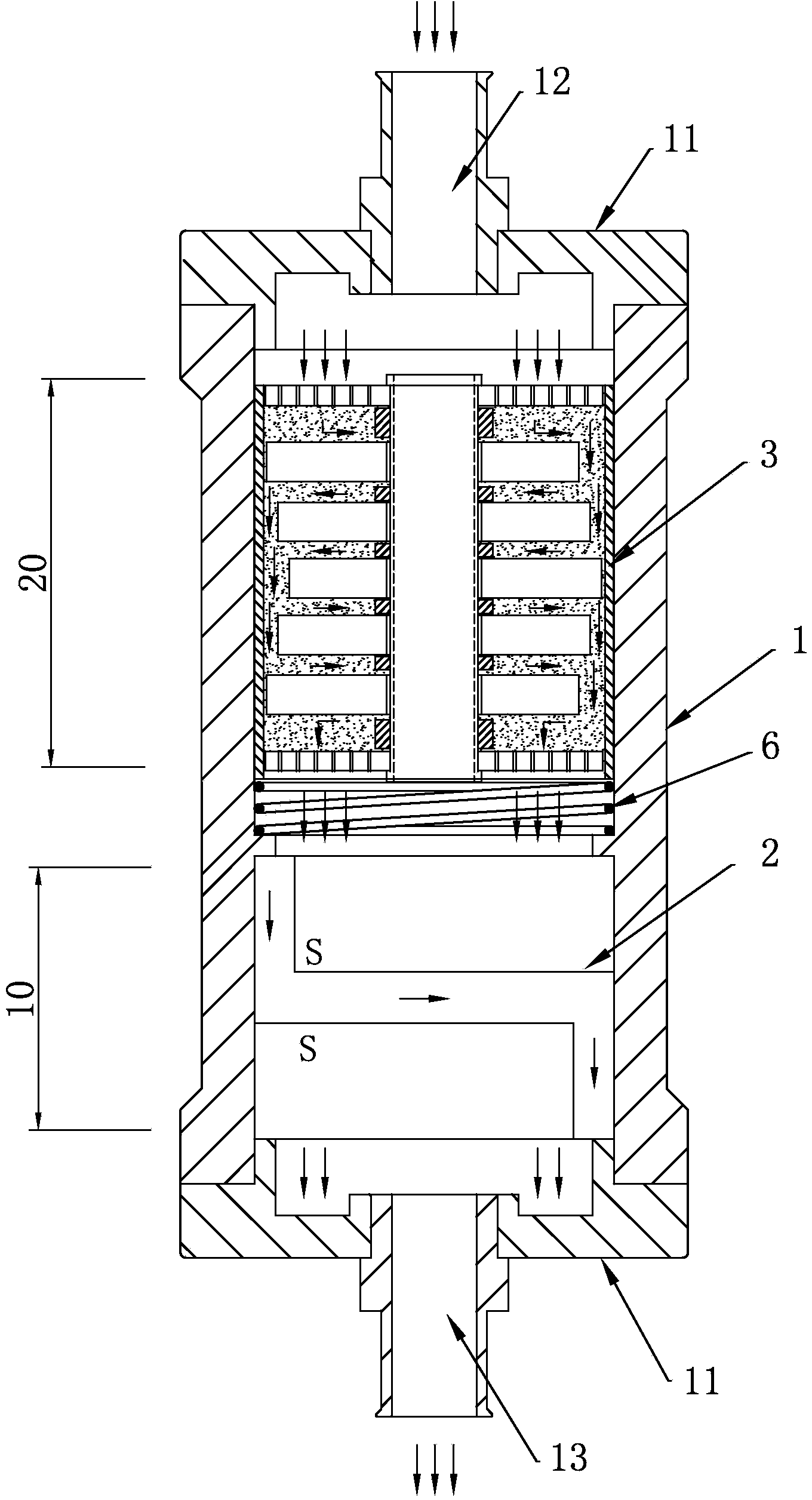

[0041] Such as figure 1 As shown, a strong catalytic zone 20 and a strong magnetic zone 10 are provided in the inner cavity of the housing 1 .

[0042] The strong catalytic area 20 is connected to the oil inlet 12 , the strong magnetic area 10 is placed under the strong catalytic area 20 , and a compression spring 6 is arranged between the strong catalytic area 20 and the strong magnetic area 10 .

[0043] 1. Powerful catalytic zone 20

[0044] Such as Figure 4 , 5 As shown, a fuel catalytic assembly 3 is provided in the powerful catalytic zone 20, the assembly is made of an inner cylinder 31 made of copper, a 250-350 mesh copper woven screen 32, a fastening guide post 33, and a plurality of magnetic ring pieces 4 And be filled with the nanometer 9 material (C e o 2 particles) composition.

[0045] The inner cylinder 31 is a hollow cylinder, which is arranged coaxially with the outer shell 1 , and its outer wall is in close contact with the inner wall of the outer shell...

Embodiment 2

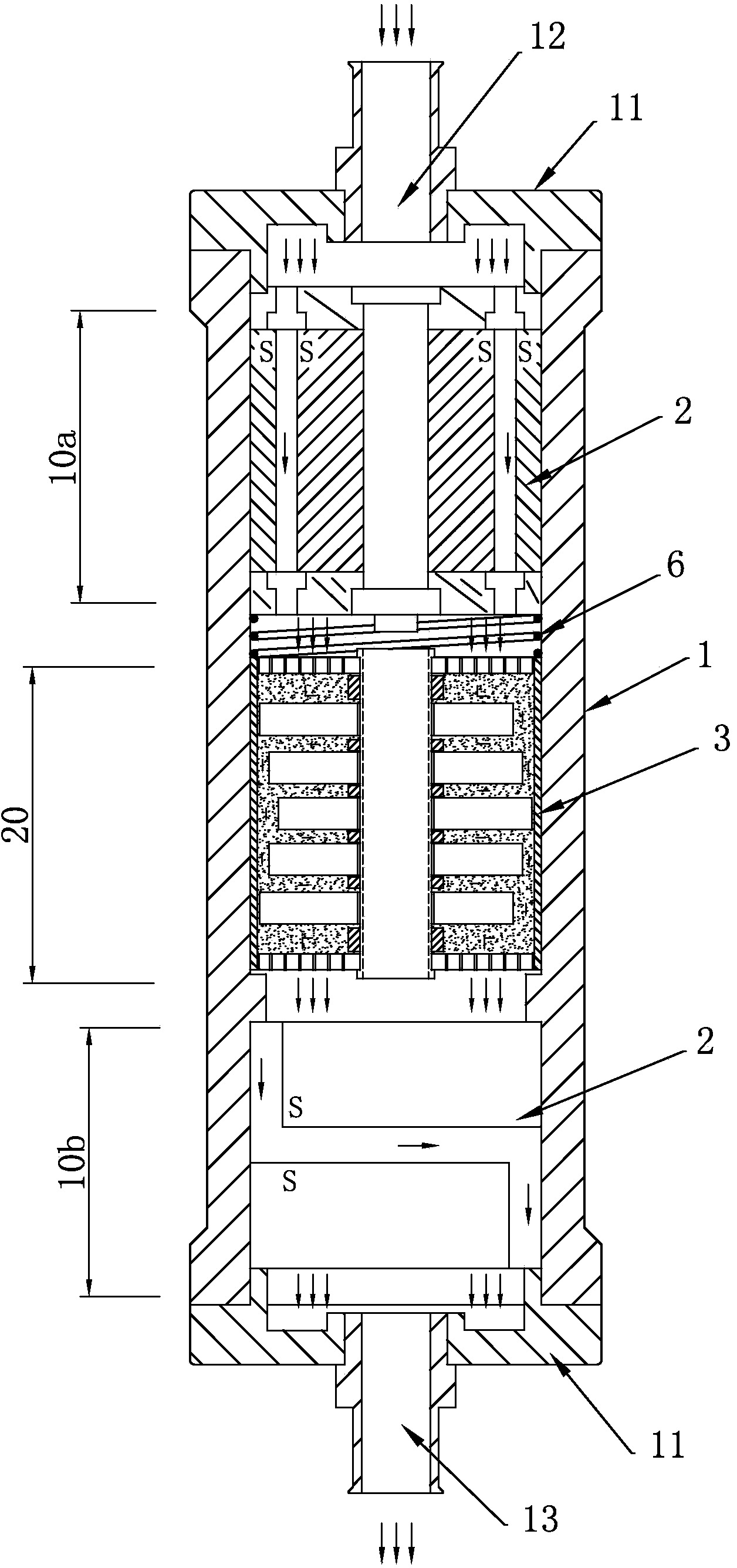

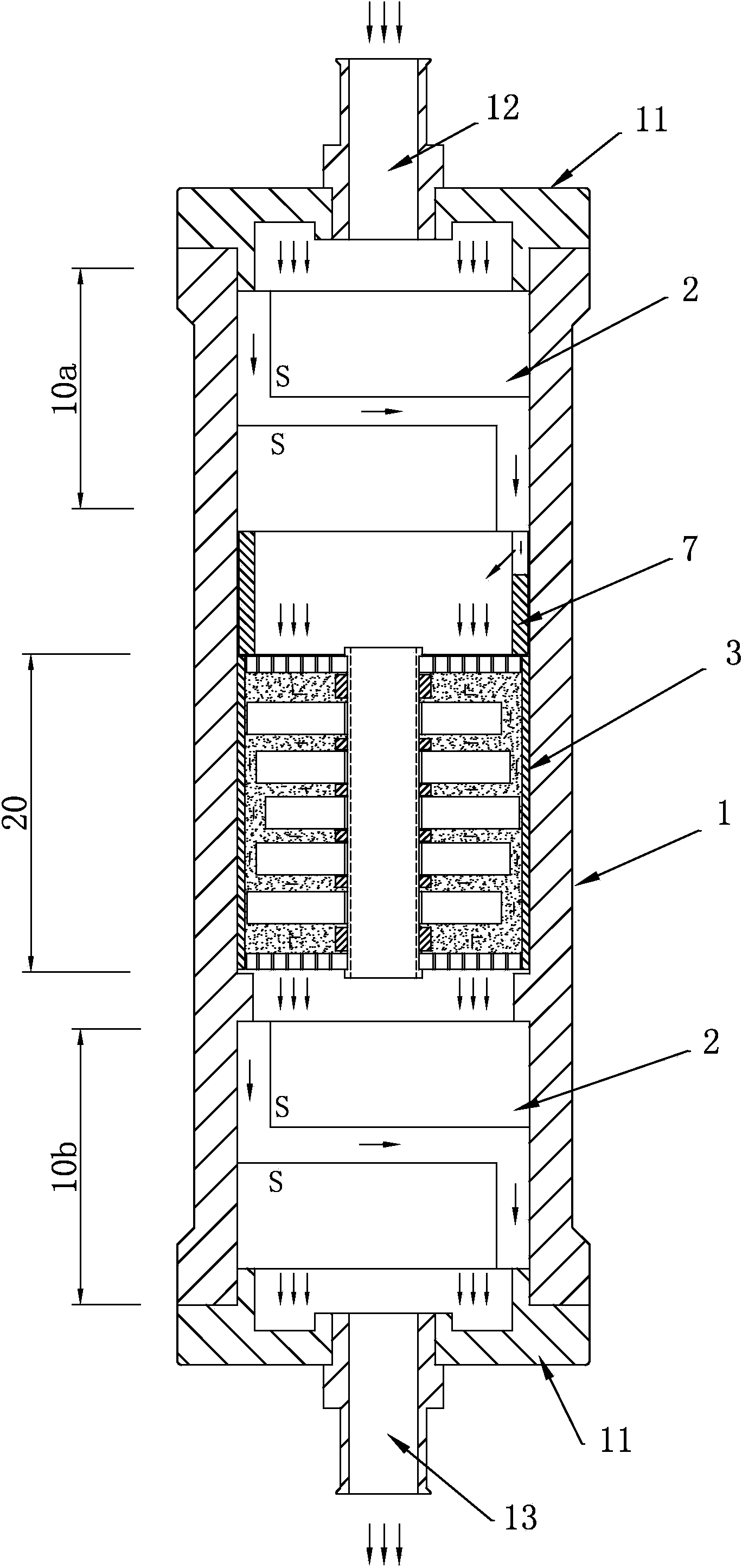

[0075] Such as figure 2 , 3 As shown, the difference between this embodiment and Embodiment 1 is that in the inner cavity of the housing 1, a strong catalytic zone 20 and two strong magnetic zones 10 are provided, and the two strong magnetic zones 10 are respectively connected to the oil inlet 12. The first strong magnetic zone 10a connected to the oil outlet 13 is connected to the second strong magnetic zone 10b, and the strong catalytic zone 20 is placed between the first strong magnetic zone 10a and the second strong magnetic zone 10b.

[0076] The composition and function of the strong magnetic assembly 2 in each strong magnetic area 10 and the fuel catalytic assembly 3 in the strong catalytic area 20 are the same as those in Embodiment 1.

[0077] 1) In this embodiment, when the ferromagnetic assembly 2 in the first ferromagnetic region 10a is the structure of the inner magnet 21 and the outer magnet 22, an oil guide is provided between the first ferromagnetic region 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com