A method of interval filling and gob-side entry retention for processing undercover gangue

A technology of empty entry retaining and gangue, which is applied in the fields of filling, earthwork drilling, safety devices, etc., can solve the problems of difficult transportation of gangue and difficulty of mechanical undercover, and achieve the effect of saving comprehensive cost, reducing transportation cost and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

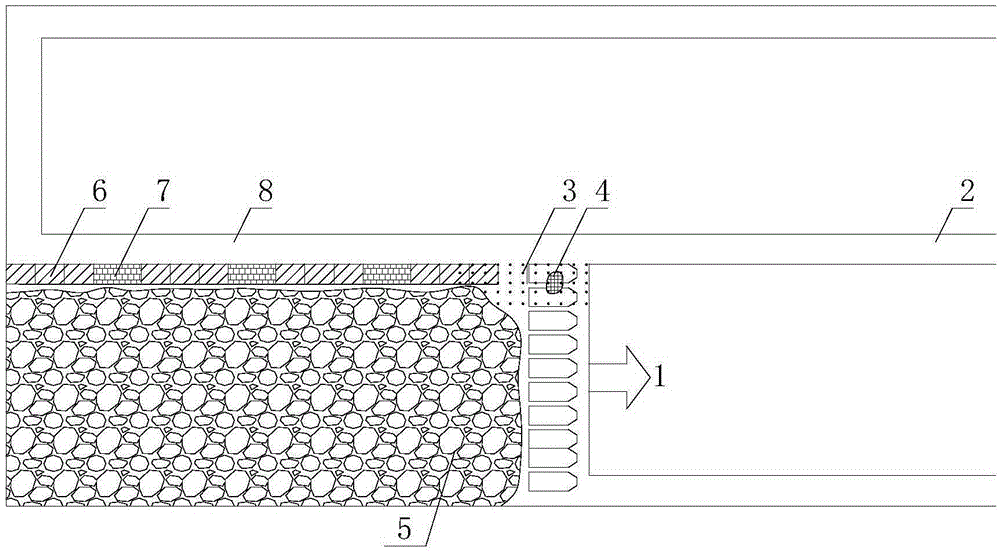

[0016] The specific steps of the interval filling gob-side entry retention method for processing undercover gangue of the present invention are as follows:

[0017] a. With the advancement of the coal mining face 1, according to the stability of the roof, after the coal is cut, the metal mesh 4 is laid in front of the end hydraulic support and the bolt / cable support 3 is carried out;

[0018] b. Erect a single hydraulic prop behind the coal mining face 1. When the coal mining face 1 advances to a filling step distance of 2 to 4 m, clean up the floating coal and floating gangue in the 8 roadways of the gob-side retaining entry and the floor of the filling area, Build the filling formwork on the side of gob-side entry 8 and goaf 5, hang filling bags in the filling formwork, secure the four corners, and use high-water materials or paste materials to construct the filling wall 6 beside the entry; Double-liquid equivalent filling pumps are arranged in the moving roadway 2 or in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com