Sustainable hybrid pervious concrete pavement structure

A permeable concrete and hybrid technology, applied in the field of concrete, can solve the problems of traffic paralysis, low compressive strength of permeable concrete, drop of urban groundwater level, etc., and achieve the effect of prolonging service life and good water permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

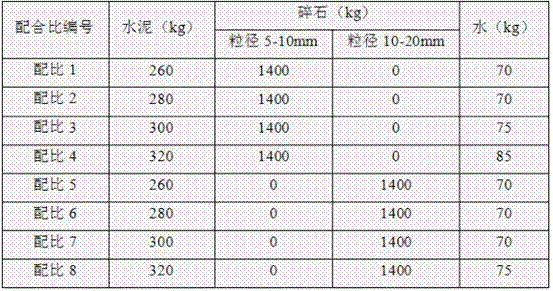

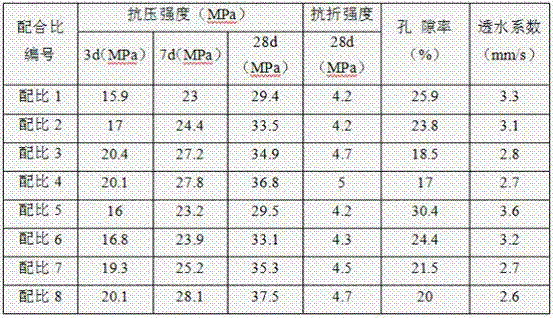

[0019] Below we will further elaborate on the permeable concrete pavement structure of the patent of the present invention in combination with the accompanying drawings and specific examples, in order to understand the structural composition and performance characteristics of the patent of the present invention more clearly, but this cannot be used to limit this invention. The protection scope of the invention patent.

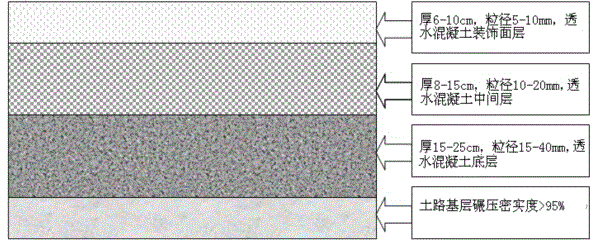

[0020] Such as figure 1 As shown, the present invention is a pavement structure of a sustainable hybrid permeable concrete pavement. The pavement structure is laid on the soil road base. The pavement structure includes a surface layer, an intermediate layer and a bottom layer from top to bottom. The surface layer The middle layer and the middle layer are made of permeable concrete with different water permeability coefficients, and the bottom layer is a crushed stone cushion, and the water permeability coefficient and porosity gradually increase from the surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com