Device for splitting cotton and eliminating metal impurities

A metal impurity, combined technology, applied in the field of cotton removing metal impurity device, can solve the problems of high energy consumption, large space occupation, increased equipment cost, fiber damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with embodiment the present invention is further described:

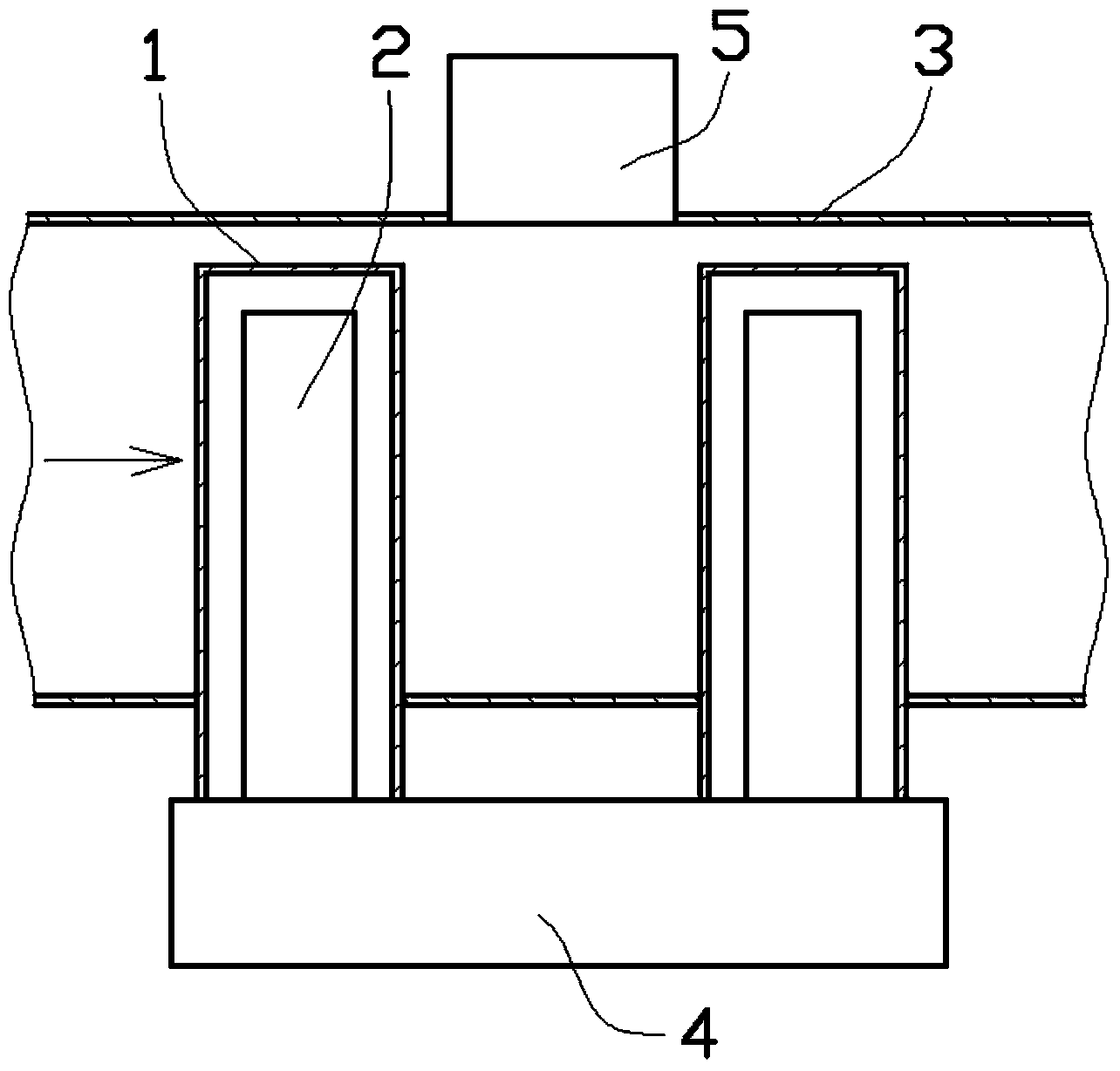

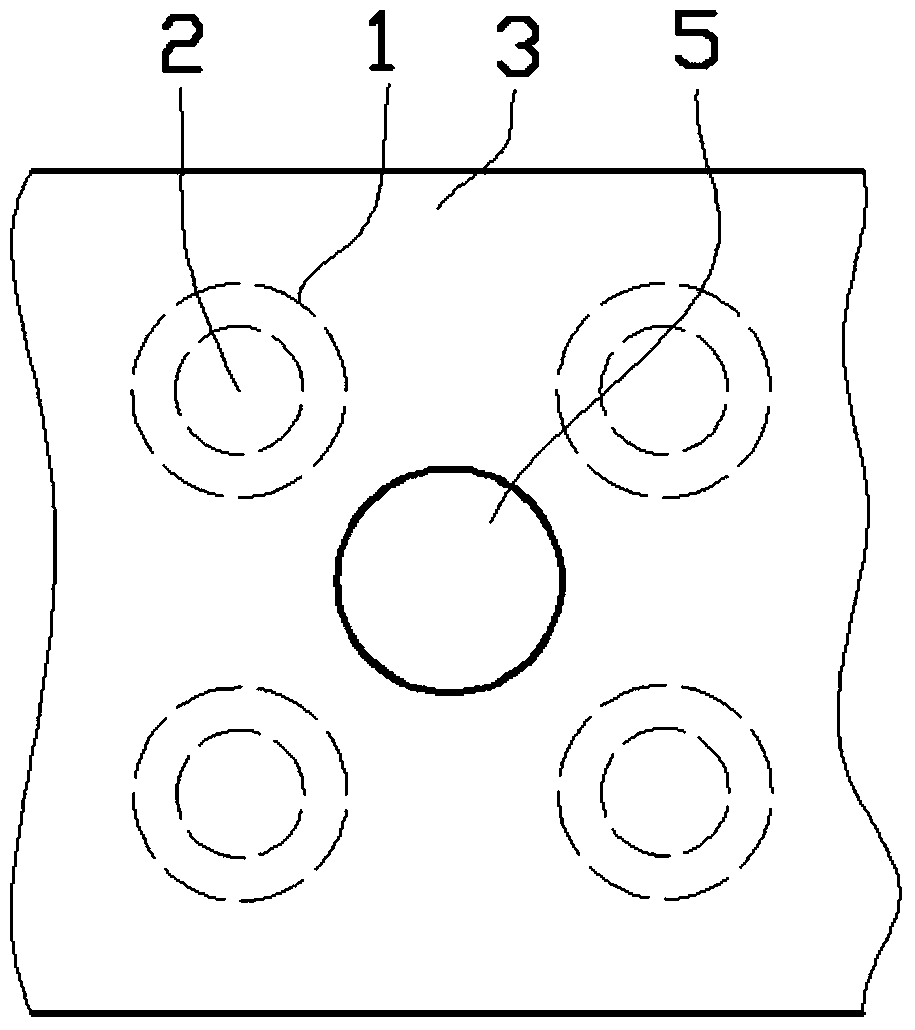

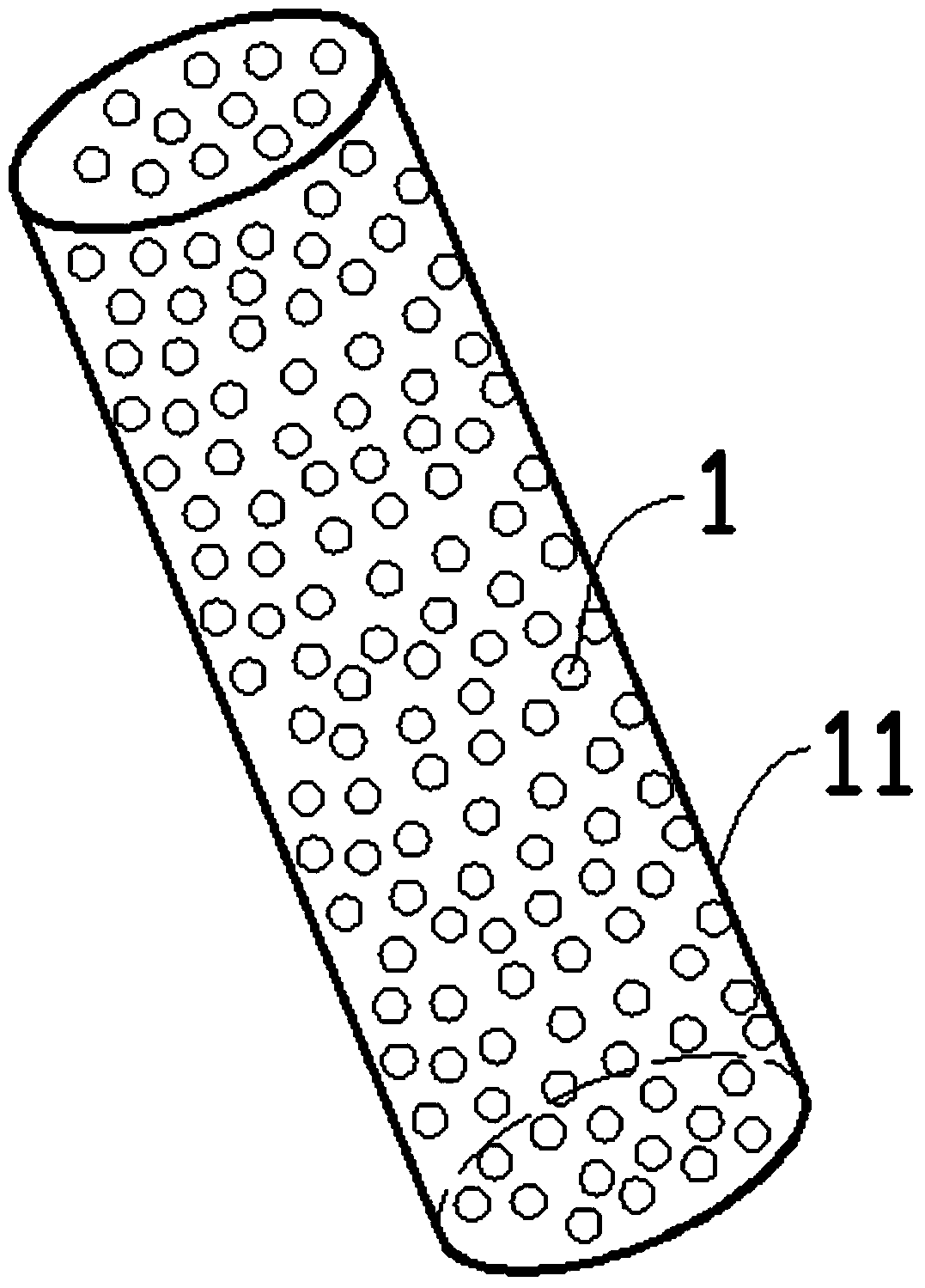

[0012] Such as figure 1 and figure 2 As shown in the embodiment, the device for removing metal impurities by opening cotton includes an isolation cylinder 1 and a magnetic rod 2; the isolation cylinder 1 is vertically assembled in the fiber conveying chamber 3. The conveying chamber 3 may be a common air conveying structure for cotton machinery or other fiber conveying chambers. The lower opening of the isolation cylinder 1 stretches out of the conveying chamber 3, such as image 3 As shown, the wall of the isolation cylinder 1 is densely covered with through holes 11 . A magnetic rod 2 is installed in the isolation cylinder 1 .

[0013] The metal impurity removal device for opening cotton is used on the cotton opening equipment. The isolation cylinder is assembled in the conveying chamber 3. When working, the fiber raw materials in the conveying chamber 3 are vibrated and shunted wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com