Cathode device for vacuum coating production line

A technology of vacuum coating and production line, which is applied in vacuum evaporation coating, sputtering coating, ion implantation coating and other directions, can solve the problem that the utilization rate of target materials cannot achieve a qualitative leap, and the assembly accuracy is difficult to meet the requirements of design accuracy. problems such as low material utilization rate, to achieve the best coating stability and uniformity, simple structure, and the effect of improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail and completely below in conjunction with the embodiments and the accompanying drawings.

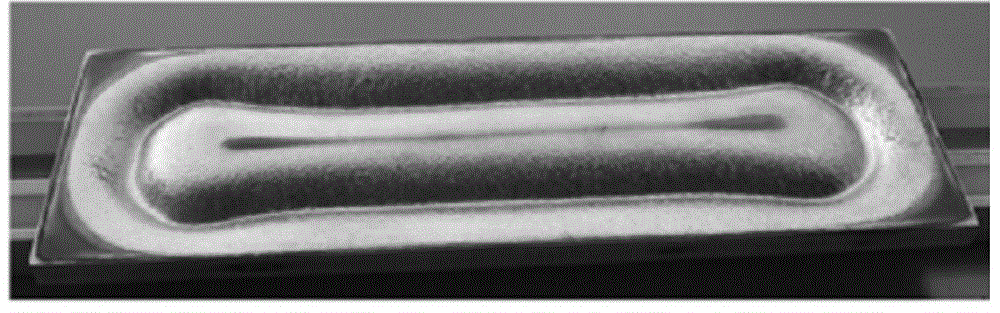

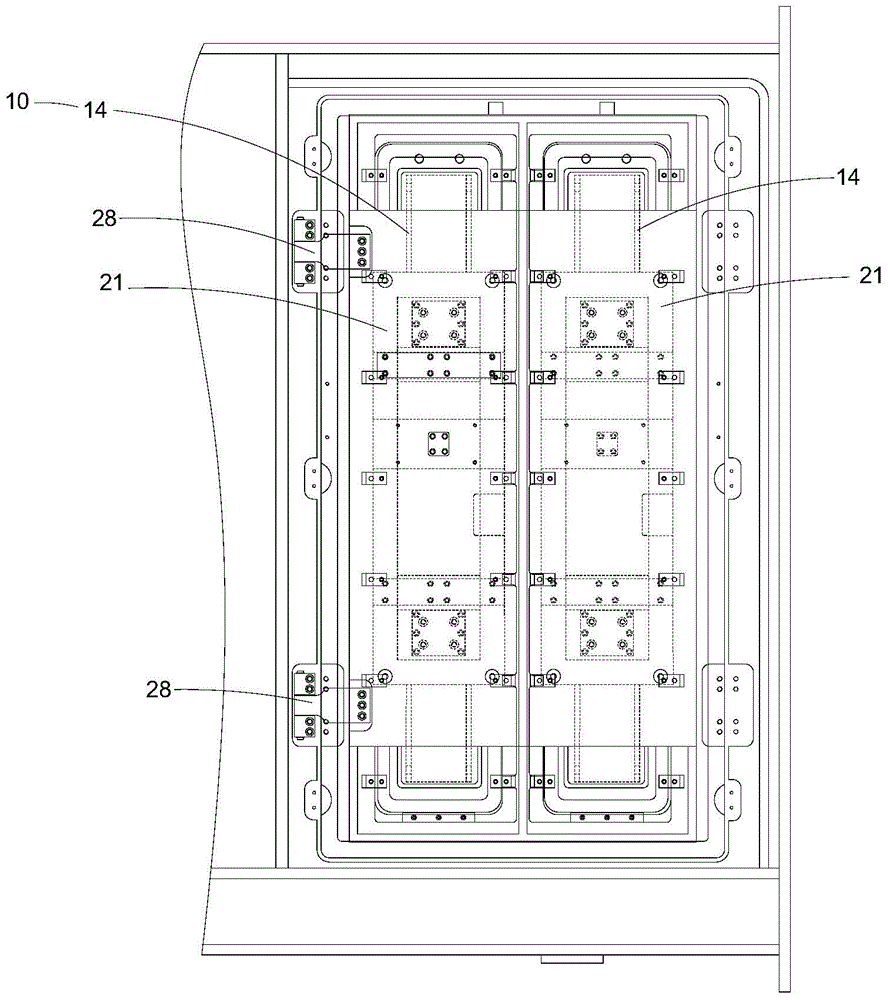

[0036] Figure 3-6 It is a schematic structural diagram of a cathode device for a vacuum coating production line provided by the present invention. in, image 3 A schematic diagram of the assembly of the cathode device, such as image 3 As shown, the cathode device includes: a cathode assembly 10 and a translation assembly 20, the cathode assembly 10 is fixedly connected to the translation assembly 20 and moves in translation with the movement of the translation assembly 20, wherein the cathode is a planar magnetron sputtering cathode. The cathode assembly and the translation assembly pass through An insulator 30 is connected.

[0037] Figure 4 The top sectional view of the cathode device for the vacuum coating production line provided by the present invention; Figure 5 It is a left sectional view of a cathode device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com