Novel ZnO-based thermoelectric thin film and preparation method thereof

A thermoelectric thin film, a new type of technology, applied in metal material coating process, vacuum evaporation coating, coating and other directions, can solve the problems of difficulty in electrical conductivity of ZnO thin film and the reduction of Seebeck coefficient, and achieve excellent thermoelectric performance and good power factor. , the effect of improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

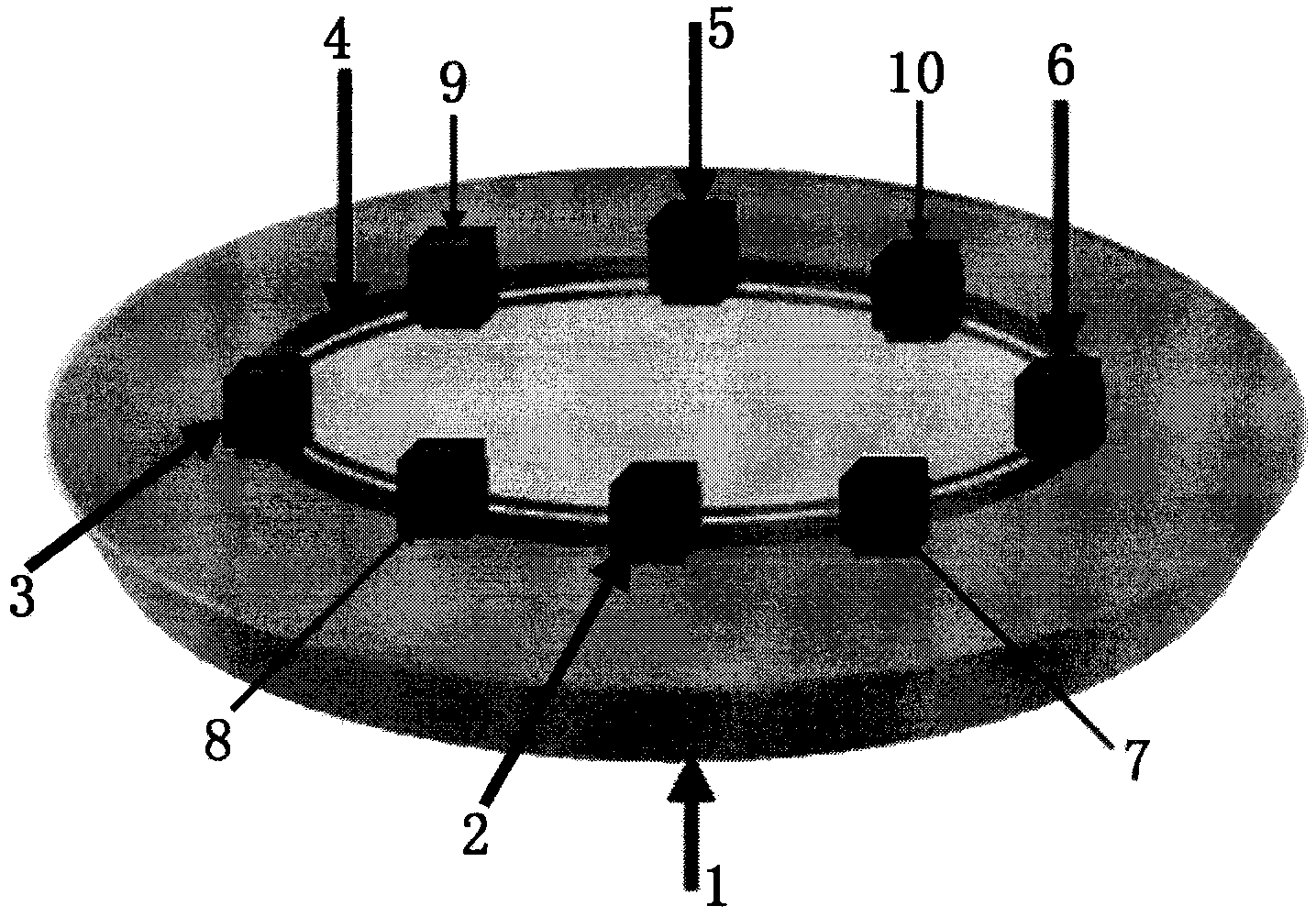

[0017] Such as figure 1 As shown, the preparation method of the new ZnO-based thermoelectric thin film is characterized in that a certain amount of metal Al small pieces and Ti small pieces are evenly placed on the metal Zn target, and suitable Ar gas and O 2 As the sputtering gas and reaction gas respectively, the novel Zn 1-x-y Al x Ti y O thermoelectric thin film. where Zn 1-x-y Al x Ti y The x and y in the O thermoelectric thin film are controlled by the area ratio of the small metal Al block and Ti small block to the entire metal Zn sputtering channel, respectively.

Embodiment 2

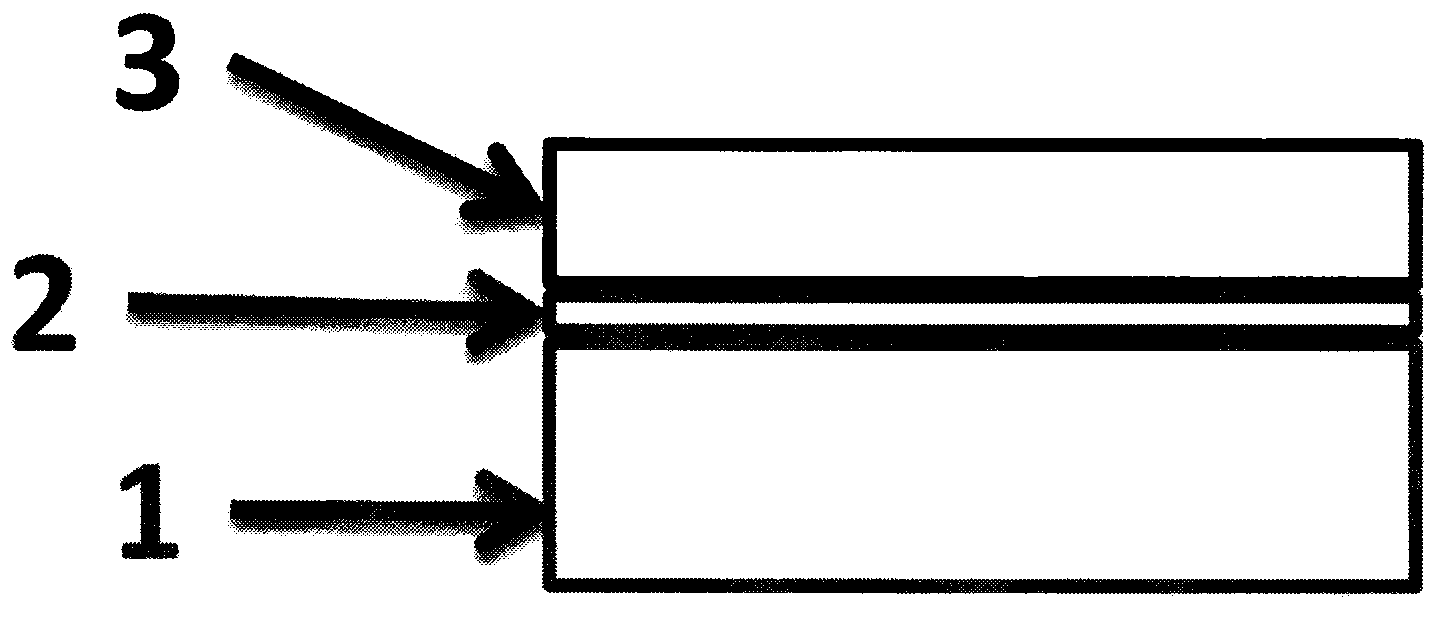

[0019] figure 2 A preparation method showing a novel ZnO-based thermoelectric thin film is characterized in that first, a Ti nano-metal thin layer is deposited on a substrate material, and then a layer of Al-doped ZnO thin film is deposited, and finally the novel ZnO film is obtained by an annealing heat treatment method. 1-x-y Al x Ti y O thermoelectric thin film. where Zn 1-x-y Al x Ti y The x and y in the O thermoelectric film are controlled by the thickness of the Ti nano-metal thin layer and the Al content in the Al-doped ZnO film.

Embodiment 3

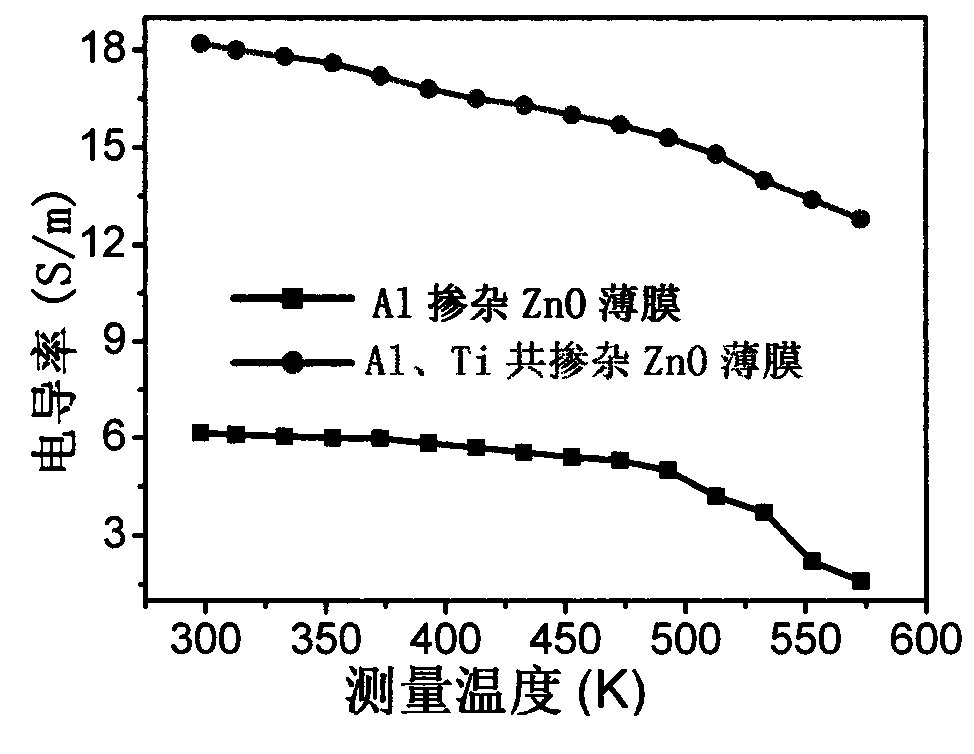

[0021] image 3 Show the novel Zn that adopts invention embodiment 2 to prepare 1-x-y Al x Ti y The conductivity of O thermoelectric film and Al-doped ZnO film as a function of temperature. The novel Zn proposed by the present invention 1-x-y Al x Ti y The conductivity of O thermoelectric thin film is higher than that of Al-doped ZnO thin film, and it decreases more slowly with the increase of test temperature. Ti co-doping provides more carriers, and the carrier mobility is also improved, so its conductivity is greater than that of Al-doped ZnO thin films.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com