Preparation method of industrial waste residue mixed ore powder

A technology of industrial waste slag and mixed ore, which is applied in solid waste management, sustainable waste treatment, cement production, etc., can solve the problems of alkali slag waste and environmental pollution, and achieve the effect of no waste slag discharge, high efficiency and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

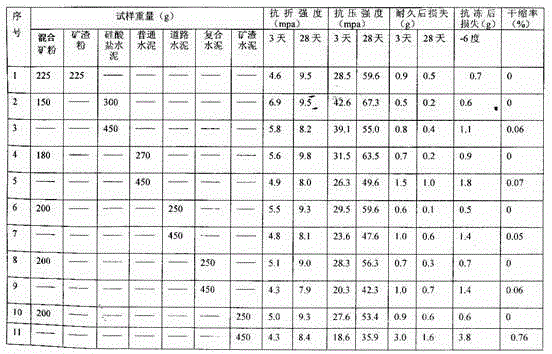

Examples

Embodiment Construction

[0010] The preparation method of industrial waste slag formula mixed mineral powder of the present invention, comprises the following steps:

[0011] A) Raw material preparation: the waste slag and alkali slag discharged from the salinization plant, the waste slag and steel slag discharged from the iron and steel plant, the waste residue straw ash discharged from the straw power plant, and the waste residue titanium gypsum discharged from the titanium dioxide factory are pushed respectively. spare;

[0012] B) Ingredients ball making:

[0013] Get alkali slag calculated as 40% by weight percentage, steel slag is 35%, straw ash is 20%, waste residue titanium gypsum is 5% and the mixed waste residue that is 100% is added to the mixing molding machine, fully in the aqueous environment After mixing, it is processed into material balls with a diameter of 5-15mm that are uniformly dispersed, without agglomeration or dust;

[0014] Or take alkali slag and calculate by weight percen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com